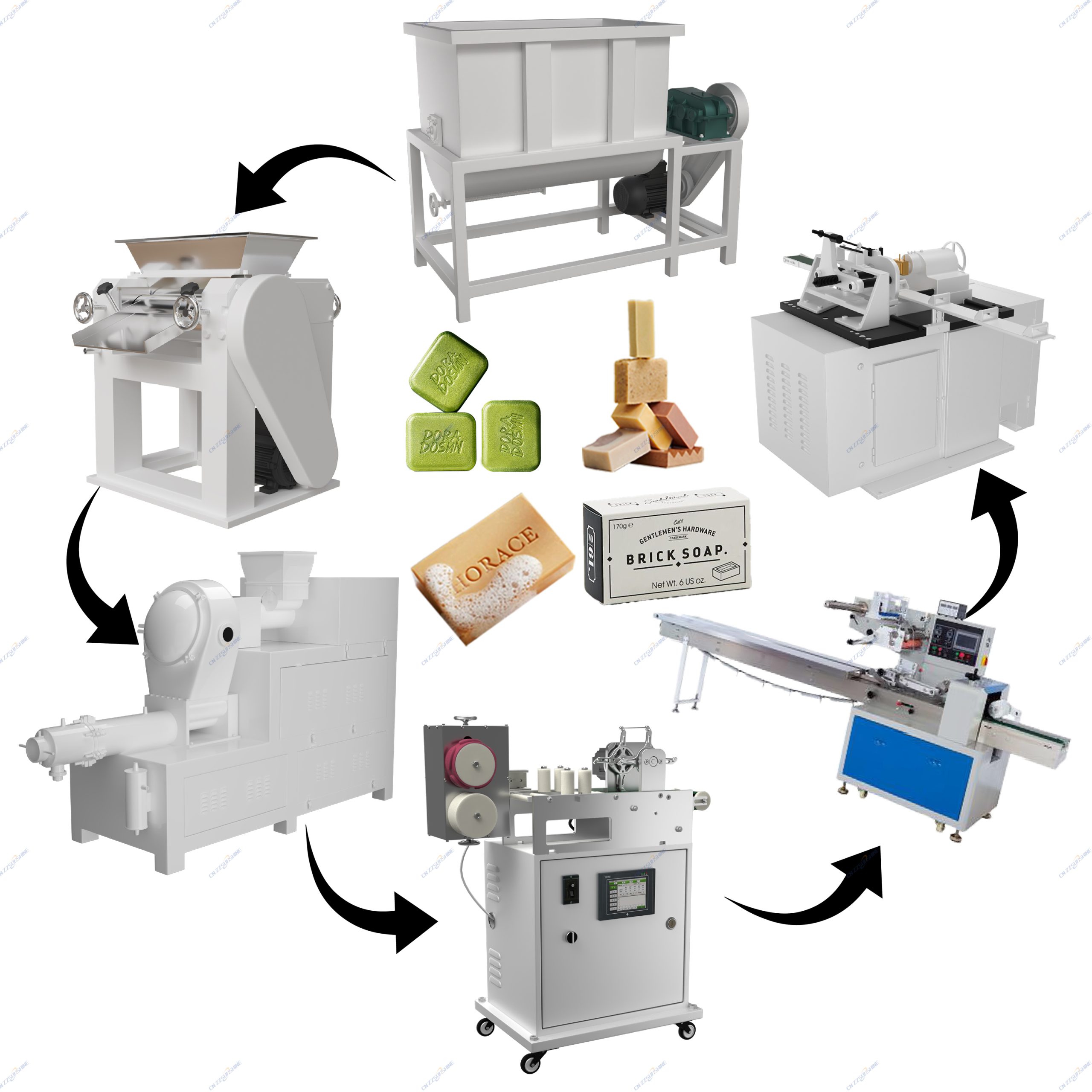

Efficiency and consistency are paramount in modern soap manufacturing. Achieving this demands more than isolated machines; it requires a seamlessly integrated **Automatic Soap Production Line**. Such a comprehensive system transforms raw materials into finished bars with minimal manual intervention, maximizing output and quality control.

The core of any high-volume **laundry soap making line** or sophisticated **toilet soap finishing line** lies in precision mixing and refining. An industrial mixer for chemical processing ensures homogeneous blending of fats, oils, lye, and additives. For products requiring ultra-fine textures, like those in a **beauty soap making line**, an **OEM three roller grinding mill** is indispensable, refining the soap mass to a smooth consistency. The refined soap base then moves to the **soap plodder machine for bar soap**, often a critical **vacuum plodder**. This component removes air pockets under vacuum, significantly enhancing the final bar’s density, lather quality, and longevity – essential for both **laundry bar soap production line** output and premium **bath soap making machine** operations.

Following extrusion, the continuous soap log requires precise sizing. Here, the **custom soap cutting machine** or **electric washing soap cutter** comes into play. These units deliver accurate, consistent cuts with clean edges, minimizing waste and ensuring uniform bar weights crucial for packaging and consumer satisfaction. Integrating an **automatic packing machine for food** (adapted for soap) further streamlines the end of the **automatic soap production line**, readying bars for boxing and shipment.

Investing in a well-designed **soap making production line** offers substantial returns. It drastically reduces labor costs, minimizes human error, ensures batch-to-batch uniformity, and increases overall throughput. Whether establishing a new **soap making machine** facility or upgrading existing capacity, focusing on the synergy between the **soap mixer**, **soap plodder**, and **cutter** within a fully automated line is the key to scalable, profitable soap manufacturing. The integration of robust components like the **vacuum plodder** and **OEM three roller grinding mill** specifically elevates the quality achievable in competitive markets.