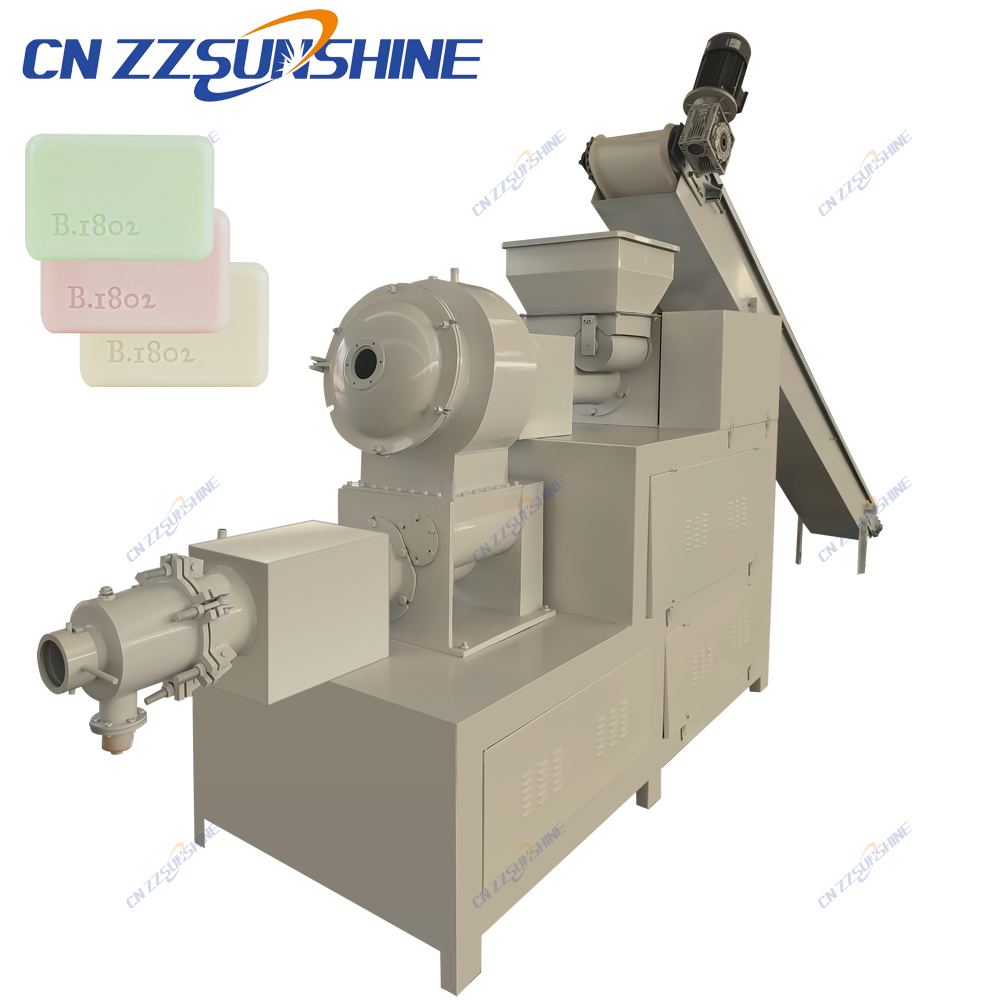

Efficient bar soap manufacturing hinges on consistent quality and minimal waste, making the vacuum plodder machine indispensable in modern soap making production lines. Unlike simple soap plodder machines, a vacuum plodder actively removes air pockets during extrusion. This crucial step prevents cracking, ensures uniform density, and significantly enhances the final bar’s longevity and lather – critical factors for both laundry bar soap production lines and high-end toilet soap finishing lines.

Integrating the vacuum plodder effectively requires compatible upstream equipment. A robust industrial mixer for chemical processing thoroughly blends oils, lye, and additives into a homogenous soap paste before extrusion. For producers requiring versatility across product ranges, from laundry soap to beauty soap making lines, a reliable soap plodder machine for bar soap capable of handling different formulations under vacuum is paramount. Downstream, precision cutting is achieved with equipment like an electric washing soap cutter or a custom soap cutting machine, ensuring bars meet exact size and weight specifications with clean edges.

The advantages of a well-designed vacuum plodder extend beyond product quality. By eliminating air, the machine reduces material waste and improves extrusion speed, contributing directly to a more profitable automatic soap production line. Reduced air content means less drying time is required after extrusion, accelerating the entire bath soap making machine process. For manufacturers aiming at high-volume markets, this efficiency gain is transformative. Furthermore, the dense, smooth texture achieved through vacuum extrusion provides a superior base for stamping, embossing, and packaging in the toilet soap finishing line stage.

Selecting the right vacuum plodder involves considering throughput needs, desired bar hardness, and compatibility with existing soap mixer and cutter units. Reputable suppliers often offer OEM configurations to match specific line requirements. Investing in this core technology within your laundry soap making line or cosmetic production setup delivers tangible returns through superior product consistency, reduced operational costs, and enhanced brand reputation for quality bar soap production.