Efficient soap manufacturing demands integrated, reliable equipment. A modern soap making production line seamlessly combines several critical processes to transform raw materials into finished bars, whether for laundry, toilet, or beauty soap. Understanding each component’s role is key to achieving high output, consistent quality, and cost-effectiveness.

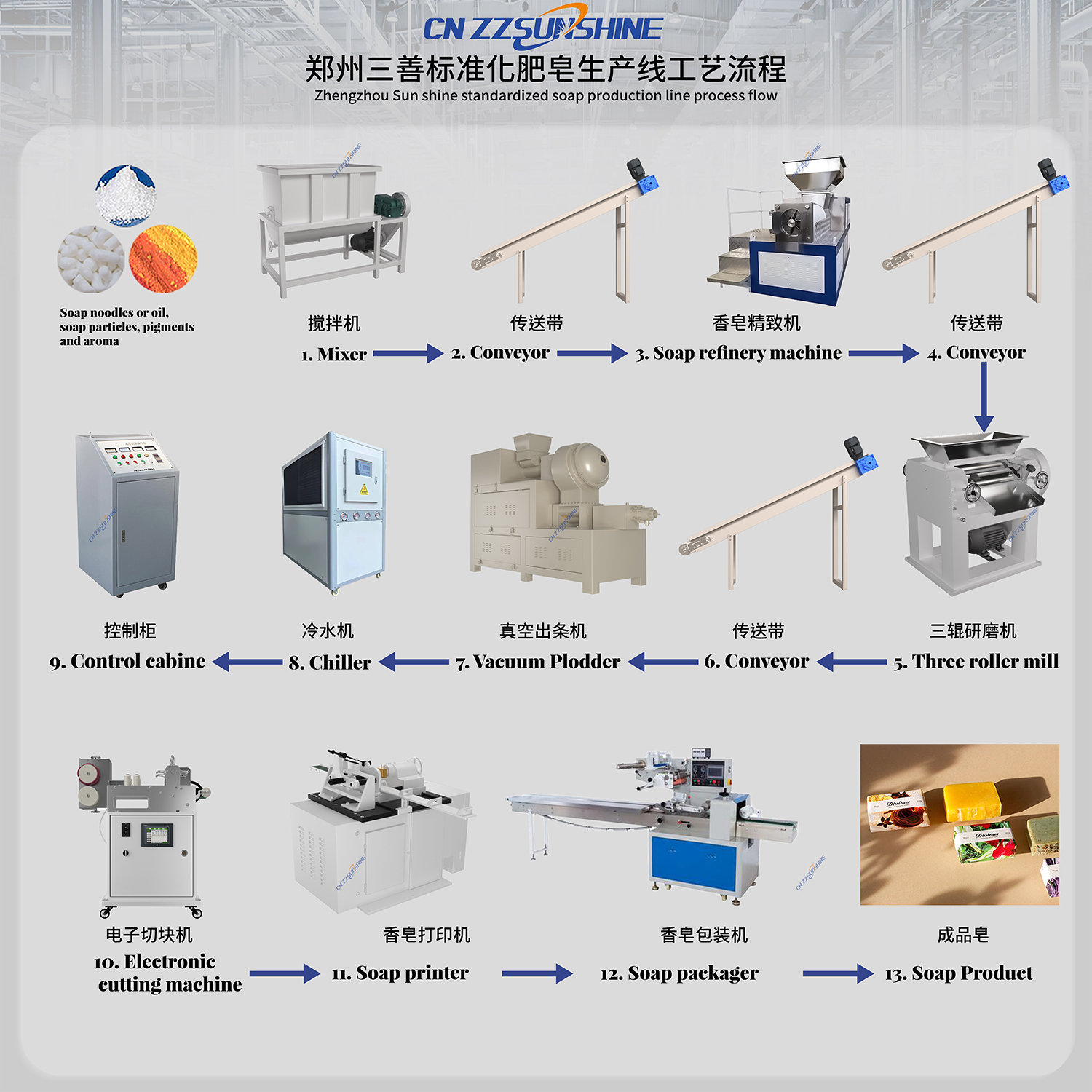

The process begins with precise ingredient handling. An industrial mixer for chemical processing ensures fats, oils, lye, and additives are blended uniformly under controlled conditions, forming the initial soap base. This homogeneous mixture is then refined using specialized milling equipment, such as a three roller mill for cosmetics-grade soap, to achieve the desired smoothness and particle size essential for premium bars.

The refined soap mass moves to the extrusion stage. A vacuum plodder is crucial here, compressing the soap to remove air pockets and create a dense, continuous log. This step significantly impacts the final bar’s hardness, lather quality, and longevity. For high-volume operations, an automatic soap production line integrates the plodder with downstream equipment.

Next, the continuous soap log requires cutting. Precision is paramount. An electric washing soap cutter or a custom soap cutting machine ensures bars are sliced to exact dimensions with clean edges, minimizing waste. For specialized shapes, an automatic block cutter machine may be employed before final stamping.

Finally, the bars enter the finishing stage. A toilet soap finishing line typically includes stamping, cooling, polishing, and wrapping equipment, giving the soap its final appearance and packaging. Similarly, a laundry bar soap production line focuses on efficient curing, stacking, and cartoning for bulk shipment. Key advantages include reduced labor costs, minimized material waste, and consistent product quality meeting stringent standards.

Investing in a well-designed laundry soap making line or bath soap making machine, incorporating high-quality components like the soap plodder, industrial mixer, and cutter, streamlines operations. Leading suppliers, including experienced China feed processing machine supplier firms often manufacturing soap equipment, offer solutions ranging from individual machines like a soap plodder machine for bar soap to complete, automated turnkey systems. Factors like desired output, bar type (laundry, toilet, beauty), and level of automation (OEM three roller grinding mill options) dictate the optimal configuration. Choosing the right soap making machine system is fundamental to competitive manufacturing.