Streamlining the manufacture of high-quality bar soaps, whether for laundry or toilet use, demands integrated, reliable equipment. A modern automatic soap production line replaces labor-intensive manual processes with precision machinery, ensuring consistent output, superior hygiene, and significant cost savings. This comprehensive system integrates several key components working seamlessly together.

The process begins with thorough ingredient preparation. Industrial mixers for chemical processing, often heavy-duty sigma blade or paddle mixers, handle the initial blending of fats, oils, alkalis, and additives, creating a homogeneous soap base. This mixing stage is critical for achieving the desired saponification and final bar properties.

Following mixing, the soap base undergoes refinement. Three-roll mill for cosmetics or soap applications is frequently employed here. These robust mills, available as OEM three roller grinding mill units, refine the soap mass, ensuring particle size reduction, uniform texture, and color dispersion – essential for both aesthetic appeal and performance in beauty soap making lines or standard bar production.

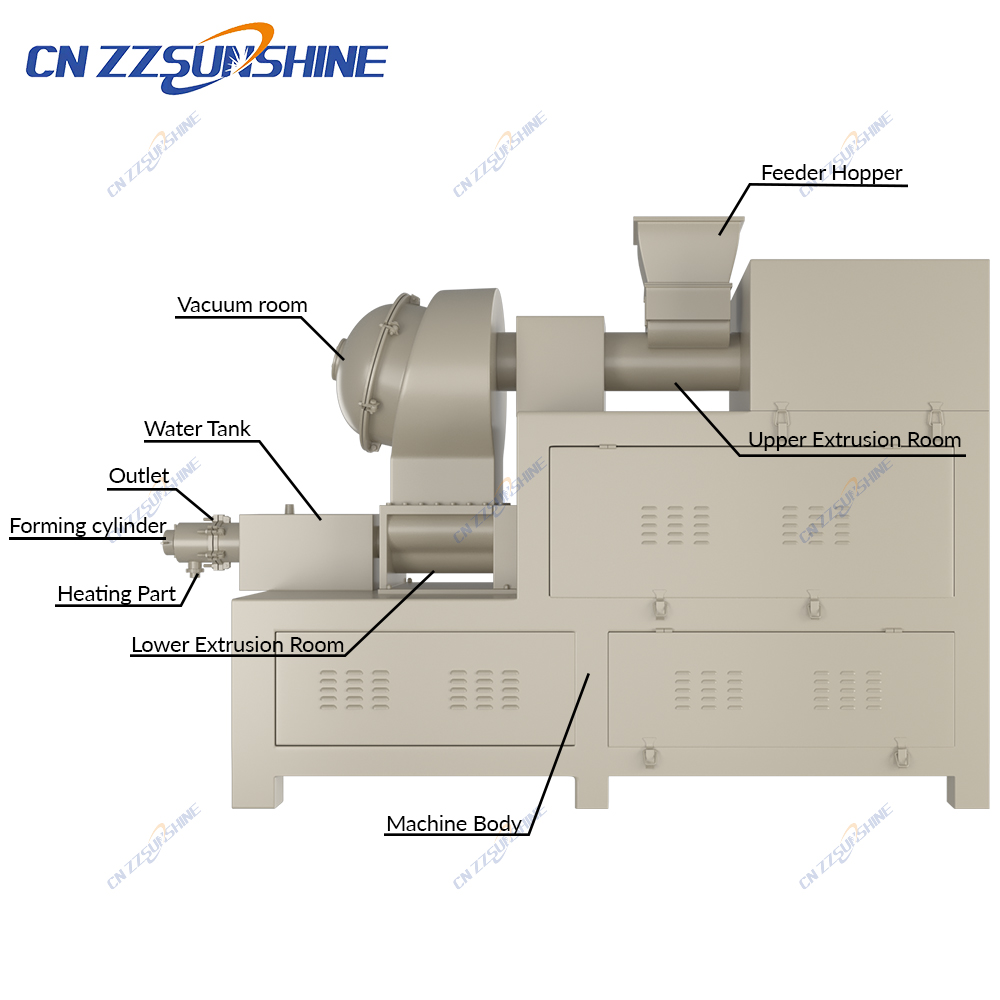

The refined soap then moves to the core of the line: the soap plodder machine. Vacuum plodder units are particularly vital. They work by compressing the soap under vacuum, effectively removing trapped air pockets. This vacuum plodder stage significantly enhances the soap’s density, translucency, lathering properties, and overall durability. The plodder extrudes continuous, solid logs of soap ready for cutting.

Cutting precision is paramount. An automatic soap cutting machine, often an electric washing soap cutter, slices the extruded logs into uniform blanks with minimal waste. These cutters offer adjustable settings for different bar sizes and weights, crucial for both laundry bar soap production lines and toilet soap finishing lines requiring exact dimensions. Custom soap cutting machine solutions cater to unique shapes or specialized requirements.

Finally, the cut bars proceed to finishing. This stage in a toilet soap finishing line or laundry soap making line might include stamping, branding, cooling tunnels, and automated packing machine for food-grade or cosmetic packaging. Integration with an industrial chiller for machinery, offering factory price industrial chiller options, is common for cooling processes or controlling equipment temperatures.

Investing in a complete automatic soap production line, sourced from reputable suppliers, delivers unmatched efficiency. It encompasses the soap mixer, vacuum plodder, cutter, and finishing equipment into one cohesive bath soap making machine system. This automation minimizes human handling, maximizes throughput, ensures product consistency crucial for brand reputation, and provides a rapid return on investment for manufacturers scaling their soap production operations.