The modern soap industry demands efficiency, consistency, and hygiene. Integrating an **automatic soap production line** is no longer a luxury but a necessity for competitive manufacturers aiming for high-volume output of quality bars, whether **laundry bar soap production line** or **toilet soap finishing line** requirements. This integrated approach replaces fragmented manual processes with a seamless, controlled system.

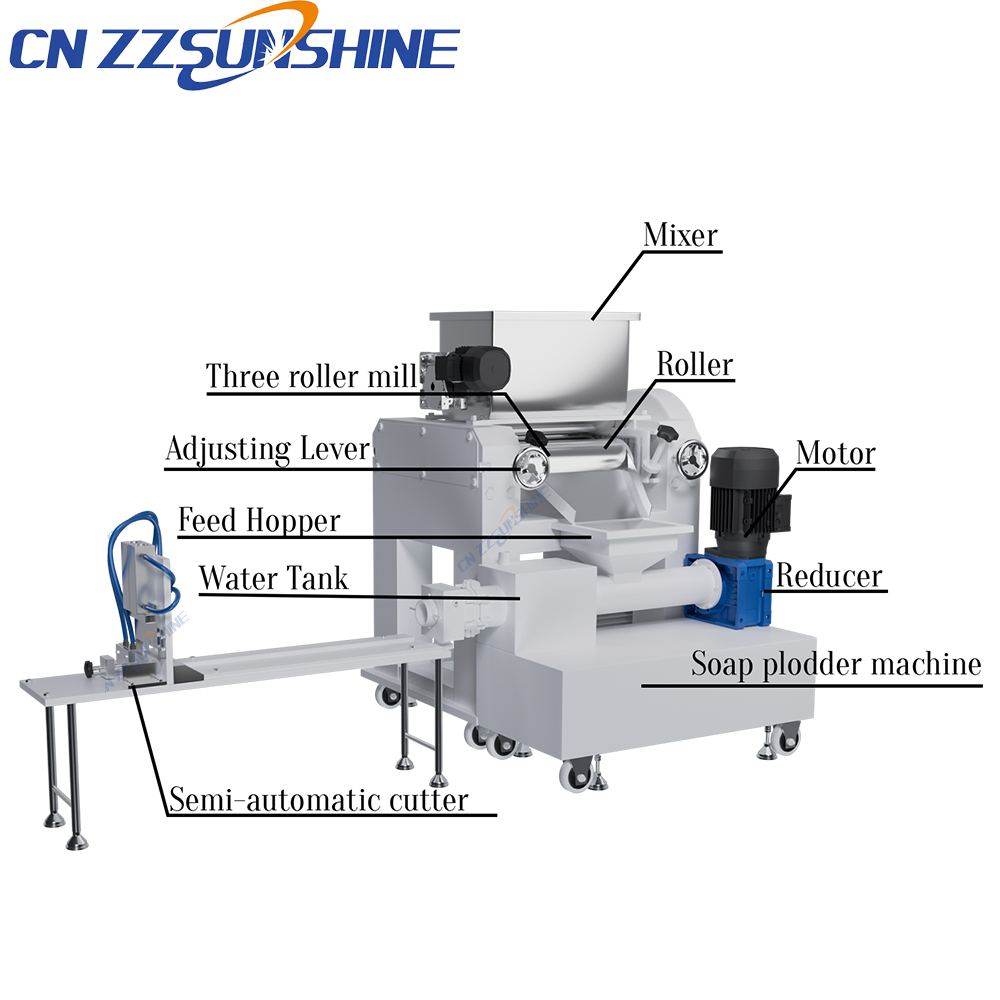

At the heart of such a line lies the **soap plodder**, often a **vacuum plodder**, which is crucial for refining the soap base. This machine compacts the mixed soap, removing air pockets under vacuum to ensure a dense, uniform texture – essential for both **laundry soap making line** durability and premium **beauty soap making line** aesthetics. Preceding the plodder, a robust **soap mixer** or **industrial mixer for chemical processing** guarantees thorough homogenization of fats, oils, lye, additives, and fragrances, forming a consistent base material.

Following extrusion from the plodder, precise cutting is paramount. A **custom soap cutting machine**, often an **electric washing soap cutter**, delivers accurate, repeatable bar sizes and shapes, minimizing waste and ensuring product uniformity crucial for packaging and consumer appeal. This automation is far superior to manual methods, especially in high-speed **bath soap making machine** operations.

The synergy of these components – the **mixing machine**, **soap plodder machine for bar soap**, and **cutter** – within a unified **automatic soap production line** delivers significant advantages. It drastically reduces labor costs, minimizes human contact enhancing hygiene, improves batch-to-batch consistency, increases overall throughput, and optimizes floor space. For manufacturers sourcing equipment, partnering with a reliable **China feed processing machine supplier** (many of whom also supply soap machinery) can offer cost-effective solutions without compromising on technology.

Implementing a well-designed **soap making production line** translates directly to higher productivity, superior product quality, and a stronger competitive edge in the demanding global soap market. The investment in automation, centered around core technologies like the vacuum plodder and precision cutter, provides a clear return through streamlined operations and market-ready products.