In the competitive world of soap manufacturing, efficiency, consistency, and quality are paramount. Implementing a well-designed **soap making machine** setup is no longer a luxury but a necessity for businesses aiming to scale. A complete **automatic soap production line** integrates several key components, each playing a vital role in transforming raw materials into finished bars ready for the market.

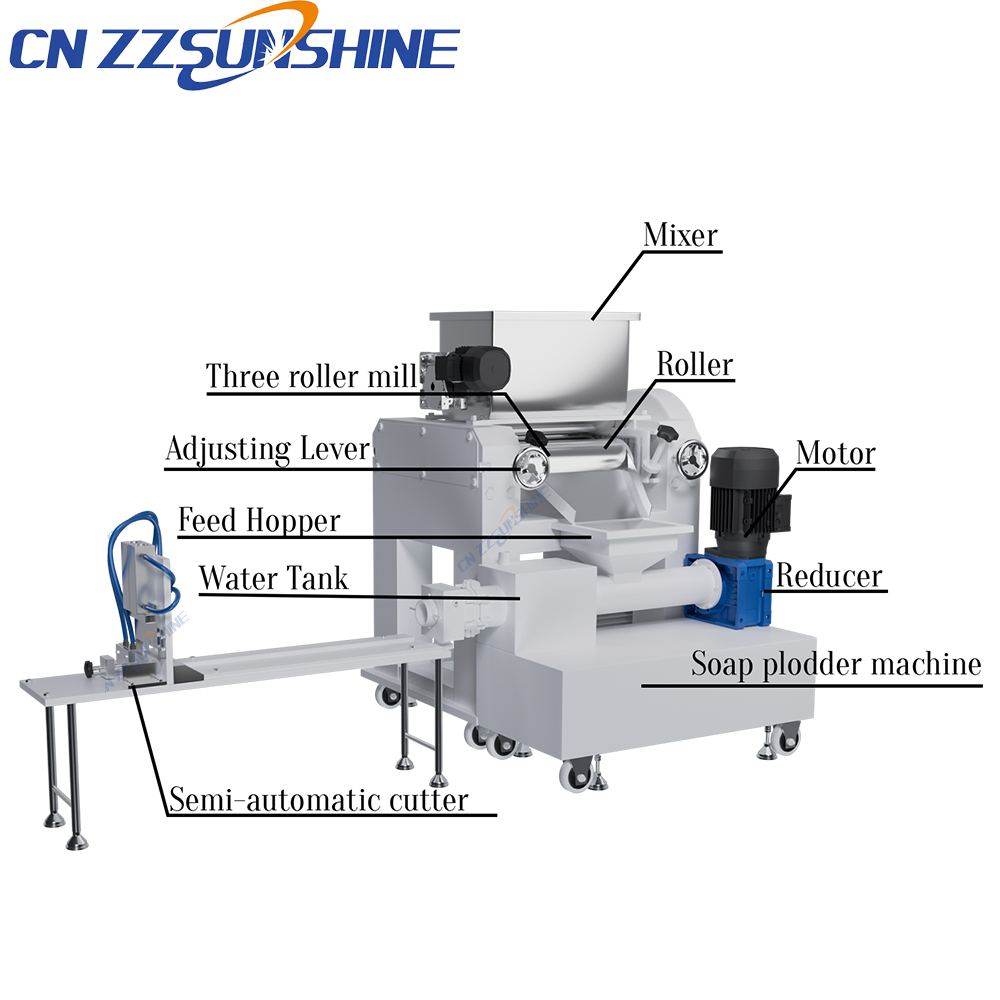

The process typically begins with precise ingredient handling. Industrial mixers, often referred to as **soap mixer** units, ensure fats, oils, lye, and additives are blended uniformly. This foundational step is critical for achieving the desired chemical reaction and final bar properties. Following mixing, the soap mass undergoes refining and extrusion. Here, **vacuum plodder** technology is indispensable. A high-quality **soap plodder** removes air pockets, compacts the soap, and extrudes a continuous, dense log with consistent texture and density – essential for both **laundry bar soap production line** and **toilet soap finishing line** operations.

The extruded log then moves to cutting. Precision is key, whether using a robust **electric washing soap cutter** for larger laundry bars or a sophisticated **custom soap cutting machine** designed for intricate shapes and sizes in **beauty soap making line** applications. Modern **automatic block cutter machine** units ensure minimal waste and uniform bar dimensions.

For comprehensive operations, integrating a **soap making production line** that includes all stages – from mixing and refining via the **soap plodder machine for bar soap**, through cutting, stamping, cooling (often aided by a **factory price industrial chiller**), and finally, **automatic packing machine for food** grade products – streamlines workflow, reduces labor costs, and significantly boosts output. This holistic approach, encompassing both **laundry soap making line** and premium toilet soap processes, allows manufacturers to cater to diverse market segments efficiently.

Choosing reliable equipment, potentially from an experienced OEM partner for specialized components, directly impacts profitability. Investing in a high-performance **soap making machine** system translates to superior product quality, reduced downtime, and the agility to meet evolving market demands.