Modern soap manufacturing demands efficiency, consistency, and scalability. Implementing a comprehensive automatic soap production line is the definitive solution for manufacturers aiming to dominate the bar soap market, whether for laundry or toilet soap applications. This integrated system seamlessly combines specialized machinery to transform raw materials into finished, market-ready bars.

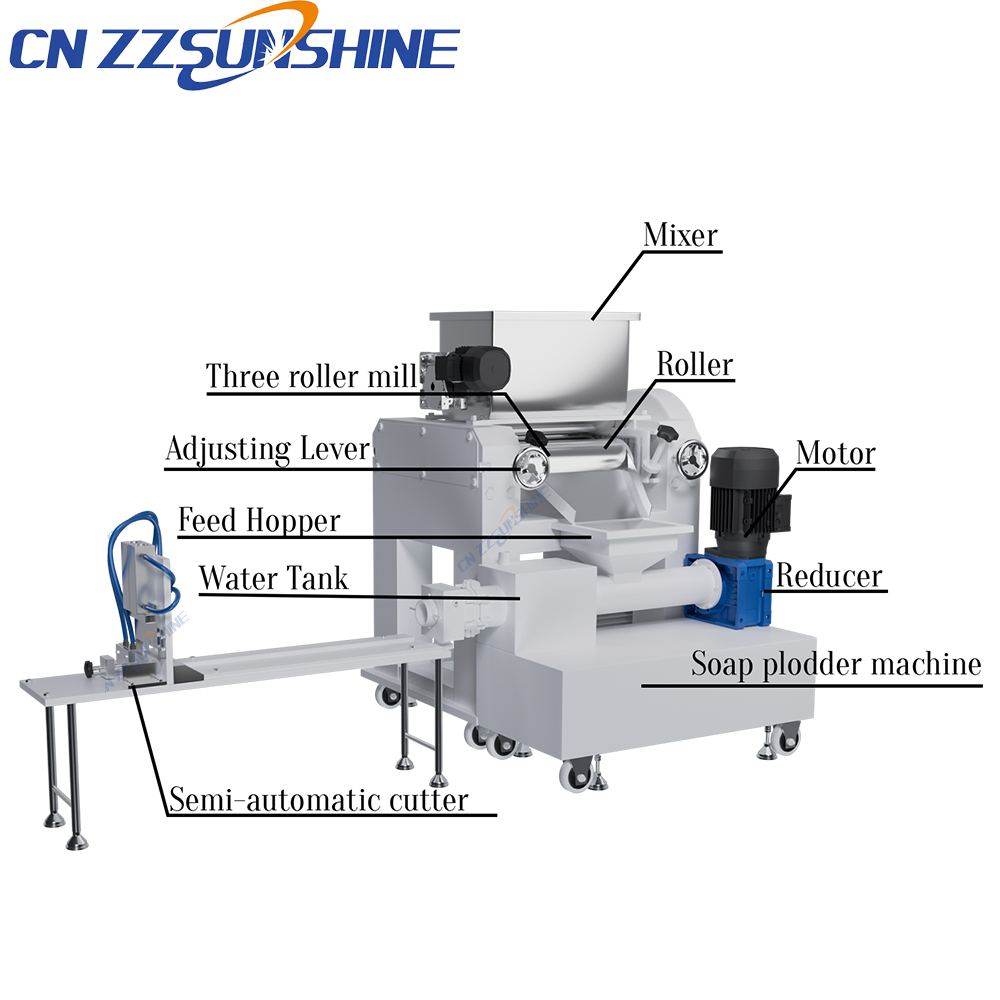

The core of any high-output bar soap production line starts with robust mixing. Industrial mixers for chemical processing ensure homogeneous blending of fats, oils, alkalis, and additives under precisely controlled conditions. This critical step directly impacts the final soap quality and saponification efficiency. The mixed soap mass then undergoes refining and extrusion, typically via a vacuum plodder machine. This essential soap plodder component removes air pockets under vacuum, resulting in a denser, smoother bar with superior lather and longer lifespan – crucial for both laundry bar soap production lines and premium toilet soap finishing lines.

Following extrusion, the continuous soap log enters the forming stage. Here, custom soap cutting machines, often sophisticated electric washing soap cutters, precisely slice the log into individual bars with minimal waste and consistent weight. For high-volume operations, integrating an automatic soap production line includes conveyors transporting bars to stamping, cooling tunnels, and finally, automated packing systems. This end-to-end automation, encompassing the entire bath soap making machine process, drastically reduces labor costs, minimizes human contact (enhancing hygiene), and ensures uniform product quality crucial for brand reputation.

Key advantages of investing in an automatic soap production line include:

* **Enhanced Productivity:** Continuous operation significantly boosts output compared to batch processing, meeting demands for laundry soap making lines and beauty soap making lines alike.

* **Superior Quality Control:** Consistent processing via the soap mixer, vacuum plodder, and precision cutter guarantees every bar meets exact specifications.

* **Reduced Operating Costs:** Automation lowers labor dependency and minimizes material waste through precise cutting.

* **Scalability:** Modular design allows lines to expand capacity or integrate new features like specific toilet soap finishing line equipment.

Choosing the right soap making machine supplier is paramount. Look for expertise in integrating all components – from the industrial mixer and soap plodder to the cutter and packing – ensuring seamless operation of your entire soap making production line. The shift towards fully automated solutions is not just a trend; it’s the strategic imperative for competitive, high-quality soap manufacturing on an industrial scale.