Implementing an efficient automatic soap production line transforms soap manufacturing capabilities. Modern lines integrate specialized equipment to handle every stage – from raw material processing to finished bar packaging – maximizing output while minimizing labor costs and human error.

The process begins with precise ingredient handling. Industrial mixers for chemical processing ensure uniform blending of oils, fats, and lye, creating a homogeneous soap base critical for quality. This mixture then undergoes refining, often utilizing a three roller mill for cosmetics-grade smoothness, essential for premium toilet soap finishing lines or beauty soap making lines requiring ultra-fine texture.

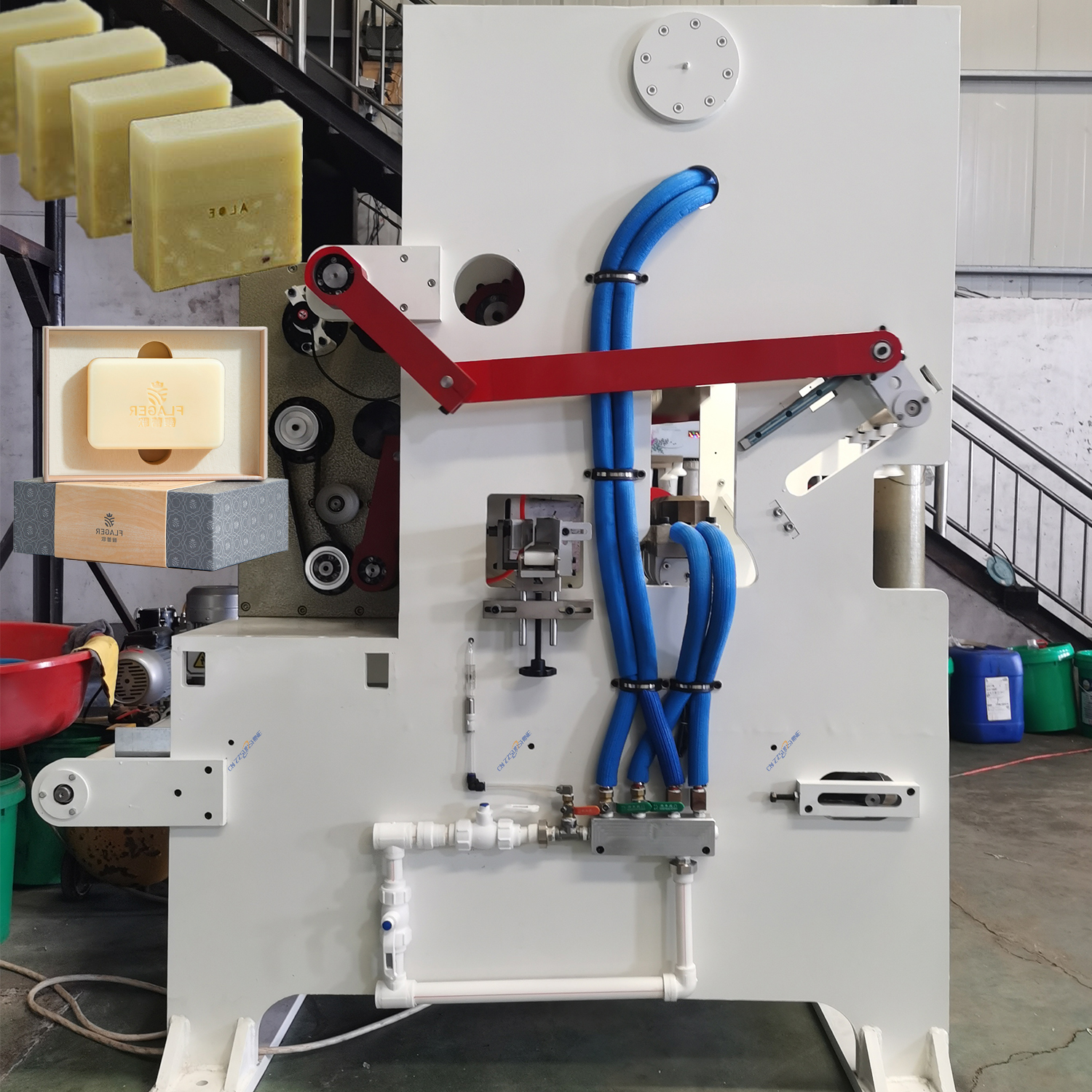

Vacuum plodder technology represents a significant advancement in soap extrusion. By removing air pockets under vacuum during compression, these soap plodder machines produce denser, longer-lasting bars with consistent structure – vital for both laundry bar soap production lines and bath soap making machines. The extruded continuous soap log then moves to cutting stations. Electric washing soap cutters or custom soap cutting machines deliver precise, programmable sizing with clean edges, minimizing waste. For high-volume operations, integrating an automatic block cutter machine further boosts efficiency.

Downstream, automatic packing machines for food-grade standards handle wrapping, labeling, and boxing, ensuring hygienic presentation. The entire automatic soap production line benefits from integrated temperature control. Factory price industrial chillers maintain optimal conditions for cooling extruded bars and stabilizing machinery like three roller grinding mills.

Successful integration hinges on selecting equipment matched to specific soap types (laundry vs. toilet vs. beauty) and desired throughput. Reputable suppliers offer OEM three roller grinding mill options and tailor vacuum plodder configurations. Key advantages include:

* **Scalability:** Modular lines grow with demand, from compact laundry soap making lines to full toilet soap finishing lines.

* **Consistency:** Automated soap mixer and plodder stages eliminate batch variations.

* **Hygiene:** Closed systems reduce contamination risks versus manual handling.

* **Cost Efficiency:** Reduced labor, lower waste (precise soap cutter operation), and continuous operation.

Investing in a cohesive automatic soap production line, incorporating a high-performance soap plodder machine for bar soap, reliable mixing machines, and precise cutters, delivers a decisive competitive edge through superior product uniformity, increased capacity, and optimized operational costs.