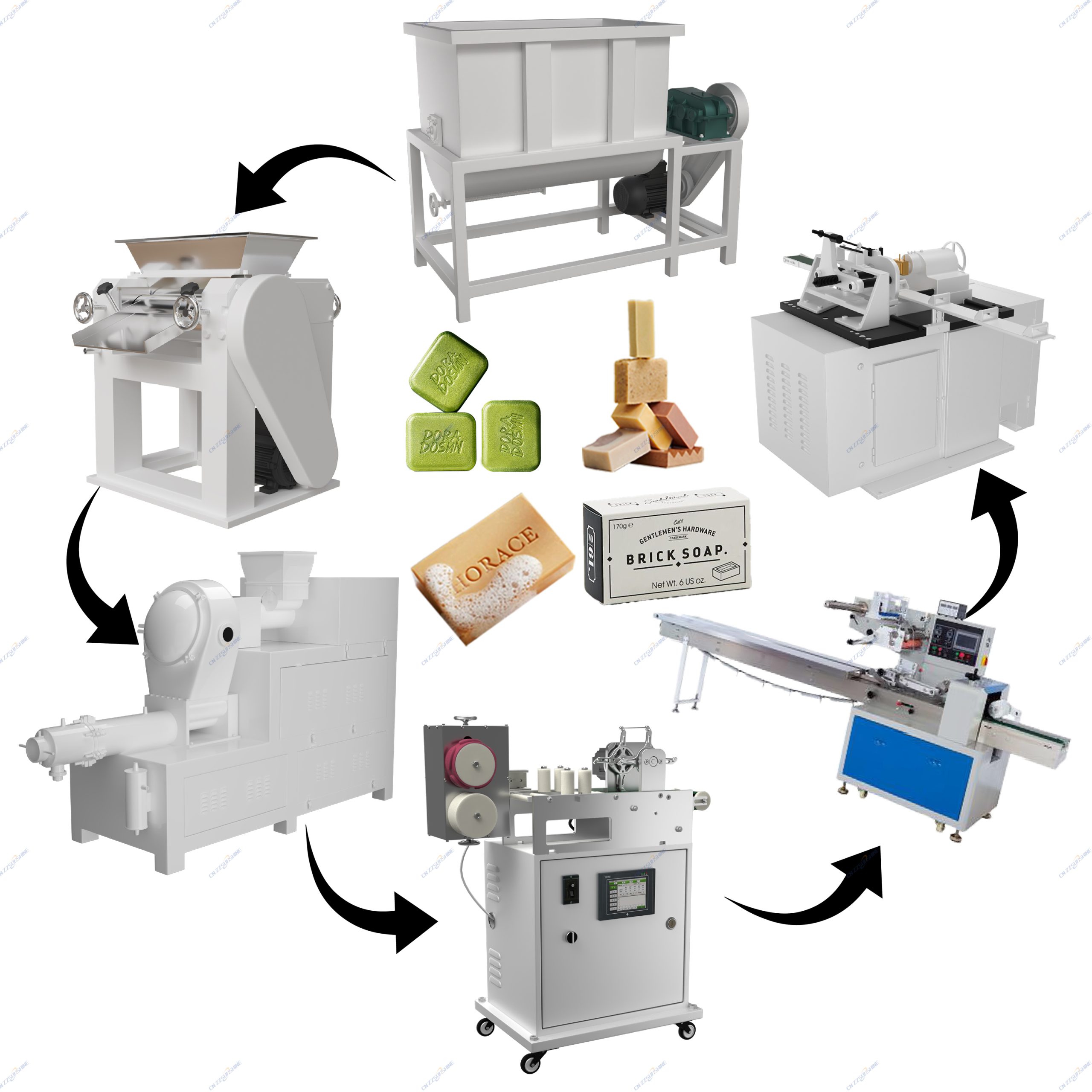

Streamlining soap manufacturing demands precision-engineered solutions. An integrated automatic soap production line significantly enhances output consistency while reducing labor costs and material waste. This seamless system typically incorporates several critical components working in unison, starting with industrial mixers for chemical processing that ensure homogeneous blending of fats, alkalis, and additives under controlled conditions.

The mixed soap base then moves to refining stages, often utilizing specialized equipment like a three roller mill for cosmetics-grade products or a high-efficiency soap plodder machine for bar soap. This stage is crucial for achieving the desired texture and eliminating air pockets. Modern lines frequently employ a vacuum plodder, which enhances density and translucency, especially vital for premium toilet soap finishing lines or luxury beauty soap making lines.

Extrusion is followed by precise cutting. While traditional cutters exist, advanced operations adopt an electric washing soap cutter or a fully custom soap cutting machine for intricate shapes and sizes, particularly in bath soap making machine setups. Consistent sizing is paramount for both laundry bar soap production lines and high-end toilet soap operations.

Finally, automated packing machines handle wrapping, boxing, and palletizing. This end-to-end automation, from the initial soap mixer through the vacuum plodder to the final cutter and packer, delivers unmatched efficiency. Leading manufacturers offer comprehensive solutions, including laundry soap making line configurations or modular systems allowing scalability. Investing in a robust automatic soap production line, featuring reliable components like a high-capacity soap plodder and precision cutter, translates directly to superior product quality, reduced downtime, and a stronger competitive edge in the global market. Optimizing throughput and minimizing waste are key ROI drivers for any soap manufacturing business.