Modern soap manufacturing demands efficiency, consistency, and flexibility. Implementing a comprehensive automatic soap production line is the definitive solution for factories aiming to meet high-volume requirements while maintaining superior product quality. This integrated system seamlessly connects key processes, transforming raw materials into finished bars ready for packaging.

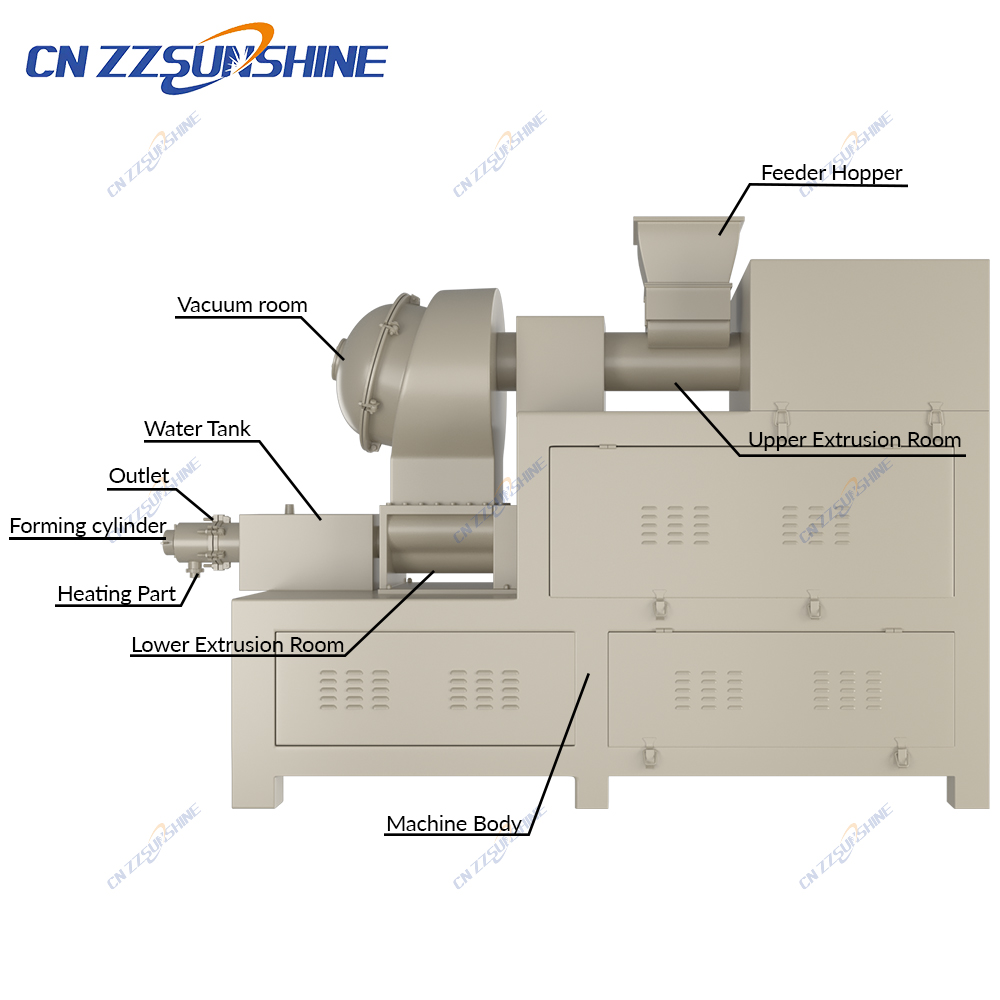

The core of any efficient soap making machine setup begins with precision mixing. An industrial mixer for chemical processing ensures fats, oils, lye, and additives are blended homogeneously under controlled conditions, forming the perfect soap base. This critical step directly influences the final bar’s properties. The mixed paste then undergoes refining and extrusion, typically using a vacuum plodder machine for bar soap. The vacuum plodder is indispensable; it removes air pockets, compacts the soap mass, and extrudes a continuous, dense log of uniform consistency – essential for premium texture and long-lasting bars. Vacuum plodder technology is particularly crucial for producing high-quality laundry bar soap production lines and sophisticated toilet soap finishing lines.

Downstream, specialized cutting equipment takes center stage. A custom soap cutting machine, often an electric washing soap cutter, slices the extruded logs into precise, uniform billets or bars with minimal waste. This automation ensures consistent sizing and shape, critical for both aesthetics and packaging efficiency. For diverse product offerings, from robust laundry soap to delicate beauty soap making lines, the ability to configure the cutter is vital. Finally, the cut bars proceed through optional stamping, cooling (where an industrial chiller for machinery might be employed), drying, and packaging stages.

The advantages of an integrated automatic soap production line are compelling. It significantly reduces labor costs, minimizes human contact with the product (enhancing hygiene), ensures batch-to-batch consistency, and dramatically boosts output capacity. Whether establishing a new laundry soap making line, upgrading a bath soap making machine setup, or expanding a toilet soap finishing line, sourcing from a reliable supplier offering robust machinery, potentially at competitive factory price industrial chiller and equipment options, is key. Look for partners experienced in OEM three roller grinding mill supply if additional refining is needed for specialty products. Investing in the right soap plodder, soap mixer, and cutter technology streamlines operations and delivers a rapid return on investment through optimized production flow and superior final product quality.