The demand for high-volume, consistent bar soap – encompassing laundry, bath, and beauty products – drives the need for integrated automatic soap production lines. These sophisticated systems replace fragmented manual processes with a seamless flow from raw material mixing to finished bar output, significantly enhancing efficiency and product uniformity.

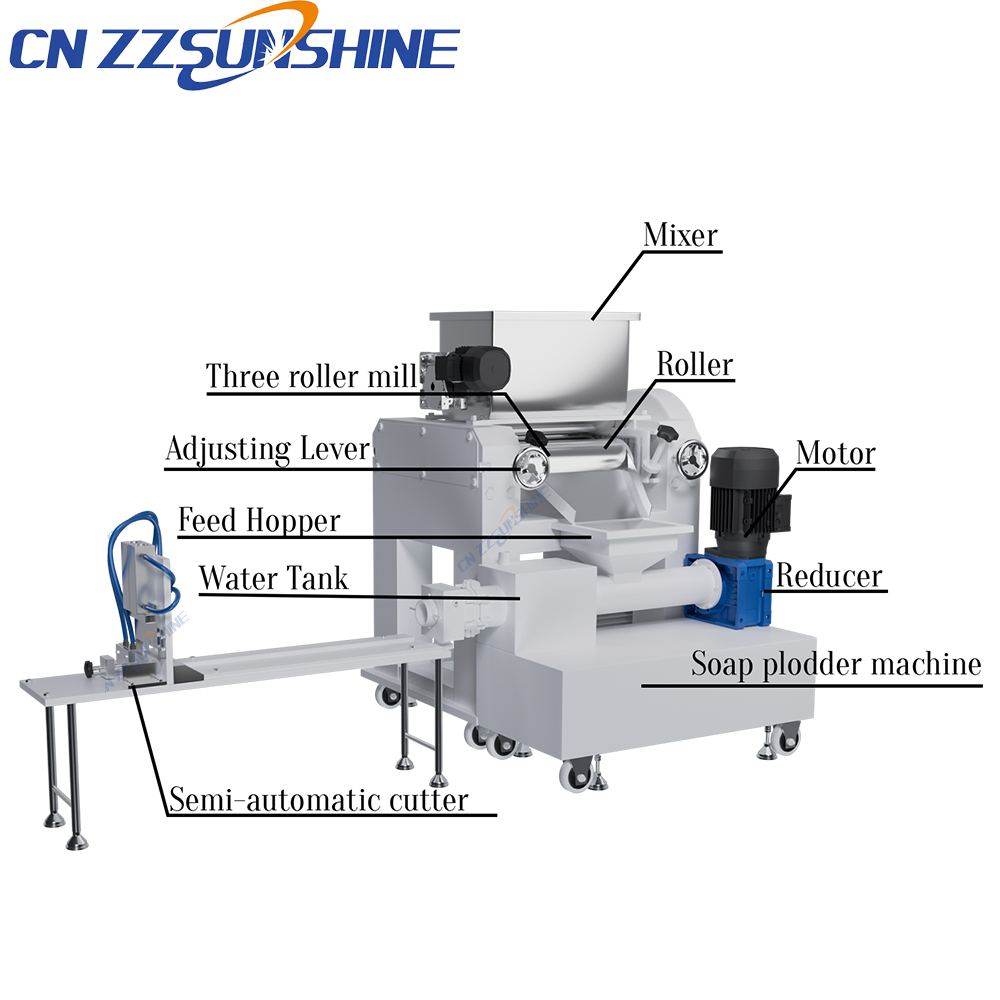

At the core lies the industrial mixer for chemical processing, precisely combining fats, oils, alkalis, and additives. This critical stage ensures homogenous blending before the soap mass moves to refining. Depending on the desired quality and application (like a high-gloss beauty soap making line), a three roller mill for cosmetics may be employed to achieve ultra-fine particle size and smooth texture.

The refined soap is then fed into the vacuum plodder, arguably the heart of a modern soap plodder machine for bar soap. Under vacuum, this unit compresses the soap, removing air pockets which cause cracking and ensures optimal density for extrusion. The continuous log extruded by the vacuum plodder maintains perfect consistency essential for both laundry bar soap production lines and toilet soap finishing lines.

Following extrusion, precision cutting is paramount. An automatic block cutter machine, often an electric washing soap cutter, slices the log into uniform billets with minimal waste. For specialized shapes or sizes, a custom soap cutting machine can be integrated. Finally, the cut bars proceed through stamping, cooling (sometimes aided by a factory price industrial chiller), and packaging – potentially via an automatic packing machine for food-grade soap products.

Implementing a complete automatic soap production line offers substantial ROI. It minimizes labor costs, maximizes throughput, guarantees batch-to-batch consistency vital for brand reputation, and reduces material waste. Whether establishing a new laundry soap making line or upgrading a bath soap making machine setup, manufacturers, particularly those sourcing reliable equipment like an OEM three roller grinding mill or a robust soap mixer, achieve superior quality control and scalability. The integration of components like the soap plodder and automated cutter within a single line represents the pinnacle of efficient, large-scale soap manufacturing today.