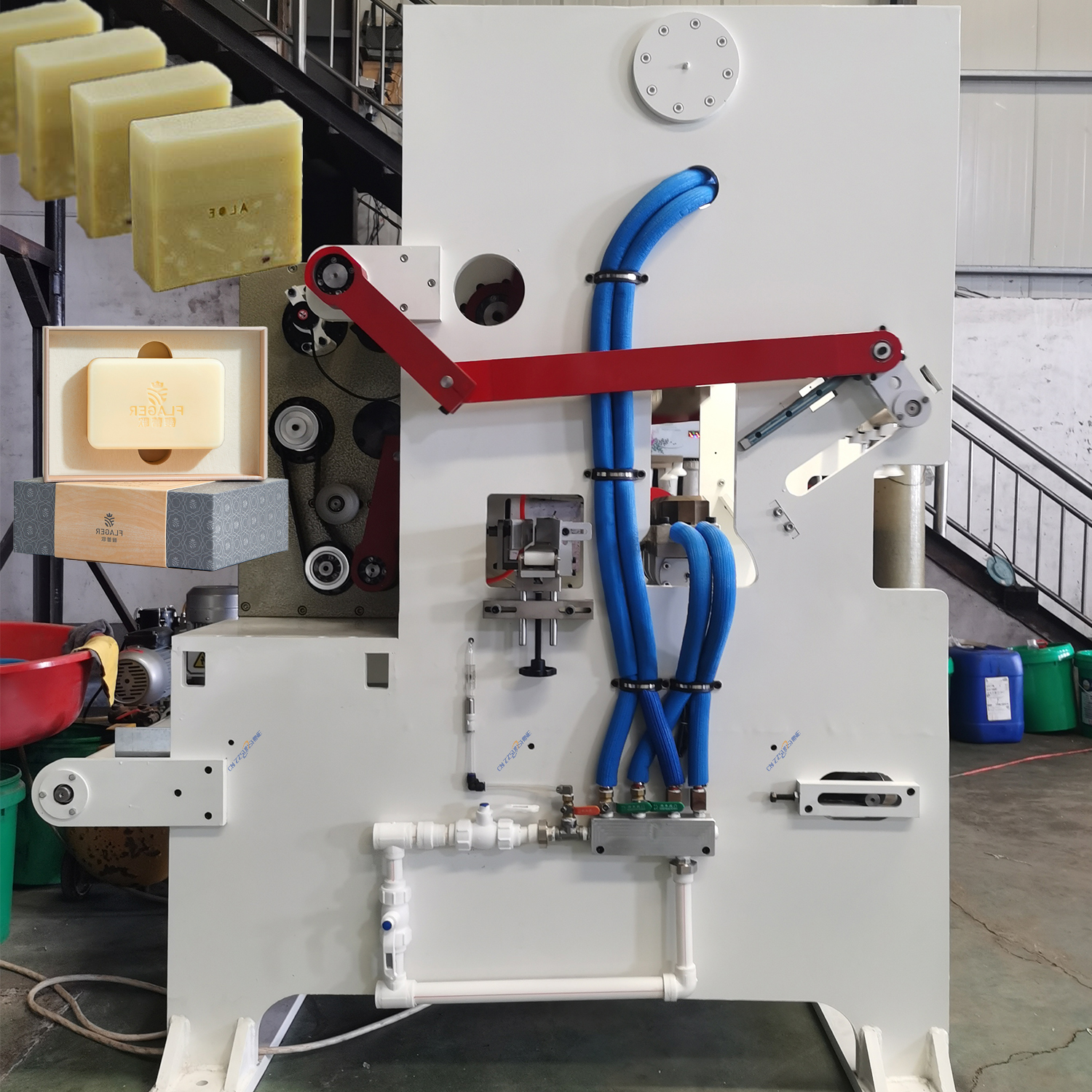

In modern industrial soap manufacturing, achieving consistent quality and high efficiency hinges on the extrusion process. This is where the **Vacuum Plodder** proves indispensable within any robust **automatic soap production line**. Unlike basic **soap mixer** units that simply combine ingredients, the **soap plodder machine** performs the vital task of refining, compressing, and de-aerating the soap mass under vacuum. This removal of air pockets is crucial for creating a **homogenous texture** essential for both **laundry bar soap production line** and **toilet soap finishing line** operations.

Integrating a high-performance **vacuum plodder** into your **laundry soap making line** or **bath soap making machine** setup directly impacts product integrity. The de-aeration prevents common defects like cracking, voids, and lamination issues in the final bars. Furthermore, the continuous compression ensures optimal plasticity, allowing downstream equipment like the **custom soap cutting machine** or **electric washing soap cutter** to perform precise, clean cuts with minimal waste – a key factor for maintaining **factory price** competitiveness.

For manufacturers seeking a complete **beauty soap making line** or a high-volume **industrial soap production line**, selecting the right plodder is paramount. Modern **vacuum plodder** units are designed for seamless integration with upstream **mixing machine** components and downstream **cutter** systems. This integration facilitates a smooth, continuous flow essential for maximizing output in **automatic soap production line** configurations. The result is a streamlined process producing dense, durable bars suitable for rigorous packaging and end-use, whether for heavy-duty laundry applications or premium toilet soap segments.

Ultimately, the **soap plodder machine**, particularly the **vacuum plodder**, is not just another piece of equipment; it’s the core technology ensuring the structural quality and consistency demanded by global markets. Investing in advanced plodder technology translates directly to superior product quality, reduced waste, and enhanced efficiency throughout your **soap making production line**, solidifying your position in the competitive industrial soap sector.