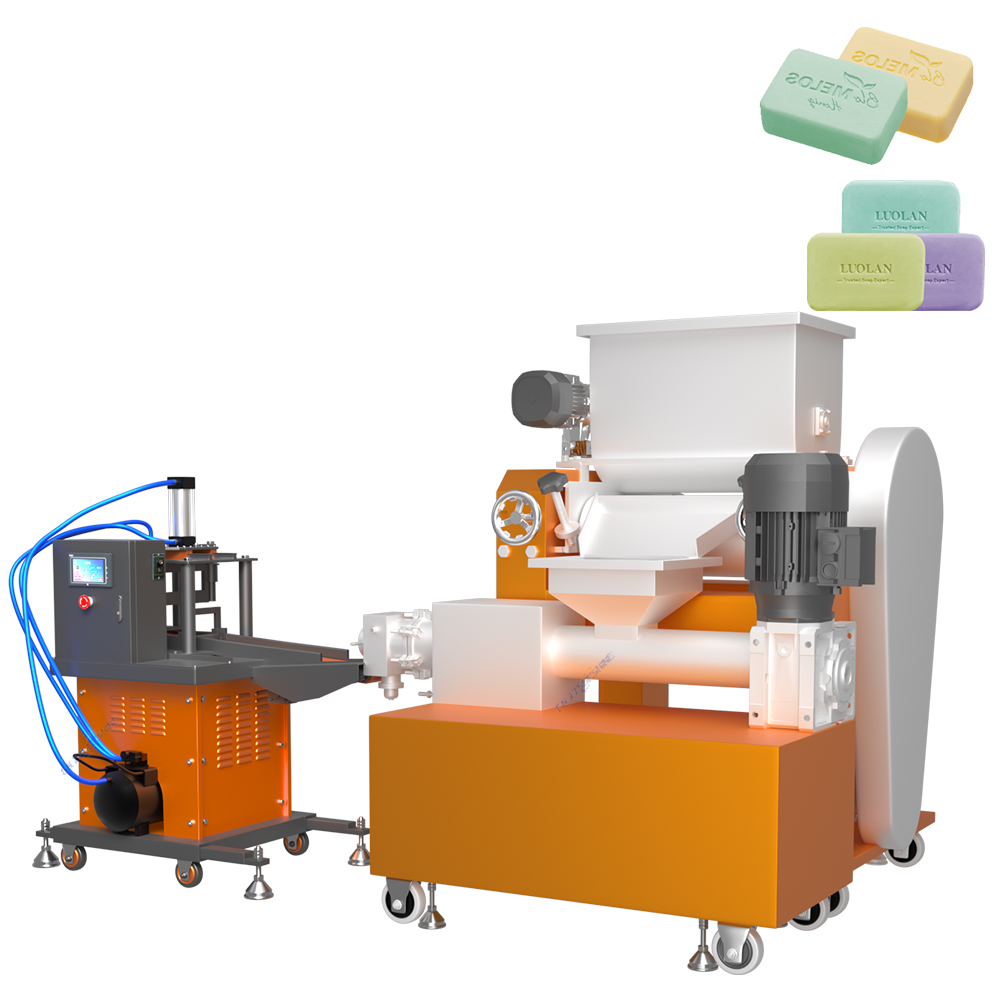

The modern bar soap market demands unwavering consistency and high-volume output. Achieving this requires investing in optimized industrial soap making lines, integrating specialized machinery like the robust soap plodder and precise soap mixer. The core of any laundry bar soap production line or toilet soap finishing line is the vacuum plodder. This critical component compacts, homogenizes, and extrudes the soap noodle mixture under vacuum, eliminating air pockets that cause imperfections and ensuring a dense, uniform bar structure essential for both laundry and bath soap making machines. Proper homogenization in the mixing machine stage is paramount before extrusion.

Integrating an automatic soap production line significantly boosts throughput and minimizes manual handling. Key automation steps include precision cutting using an electric washing soap cutter or a custom soap cutting machine tailored to specific bar dimensions and shapes – crucial for both laundry soap making lines and beauty soap making lines where aesthetics matter. Automation ensures consistent bar weight and size, reducing giveaway and maximizing yield. For manufacturers seeking flexibility, partnering with an experienced OEM provider allows for bespoke solutions, such as integrating a specific three-roller mill for cosmetics-grade refining if producing specialty beauty bars alongside standard toilet soap.

The efficiency gains from a well-designed soap making production line are substantial. Reduced labor dependency, minimized waste through precise soap cutting, and consistent product quality directly translate to lower operational costs and enhanced competitiveness. Whether establishing a new laundry soap making line or upgrading an existing bath soap making machine setup, focusing on the synergy between the vacuum plodder, mixer, and cutter within the automated framework is key to unlocking superior product quality and factory floor productivity. Selecting machinery from reputable suppliers, including established China soap machinery manufacturers, ensures reliability and access to technical support for sustained operation.