Designing a robust **soap making production line** demands meticulous attention to each processing stage to ensure consistent bar quality, operational efficiency, and cost-effectiveness. Whether establishing a new **laundry bar soap production line** or upgrading an existing **toilet soap finishing line**, selecting the right integrated machinery is paramount.

The core process begins with precise saponification and mixing. Utilizing a high-shear **soap mixer** or **industrial mixer for chemical processing** ensures uniform blending of fats, oils, and caustics, forming the foundational soap base. This homogeneous mixture is then refined to achieve the desired smoothness. Incorporating a **three roller mill for cosmetics** grade soap or a robust **OEM three roller grinding mill** effectively reduces particle size and eliminates grittiness, crucial for both **laundry soap making line** outputs and premium **beauty soap making line** products.

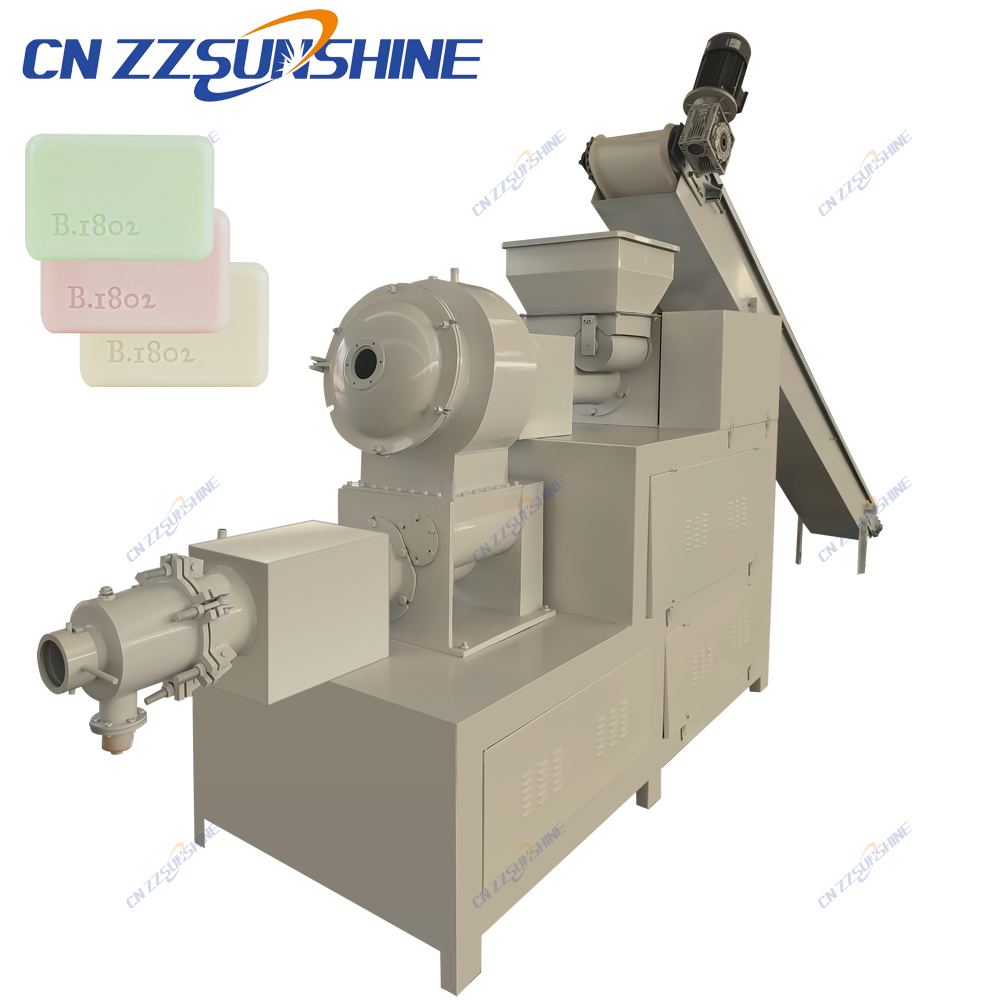

Following refining, the soap enters the critical extrusion phase. A **vacuum plodder** is indispensable here, removing air pockets under controlled vacuum conditions. This step dramatically enhances bar density, translucency, and longevity. The **soap plodder machine for bar soap** compresses the noodle-like soap strands into a continuous, dense log ready for forming. For high-volume operations, integrating an **automatic soap production line** significantly boosts throughput, minimizing manual handling.

The formed log then proceeds to cutting. Precision is key. A **custom soap cutting machine** allows for exact sizing tailored to specific bar weights and shapes, while an **electric washing soap cutter** offers clean, consistent cuts with minimal waste. For fully automated setups, an **automatic block cutter machine** seamlessly integrates into the line after extrusion.

Finally, temperature control throughout the process, particularly during milling and plodding, is vital. Employing a reliable **industrial chiller for machinery** maintains optimal soap viscosity and plasticity, preventing equipment overheating and ensuring smooth operation. Efficient **automatic packing machine for food** grade standards often completes the line, wrapping bars securely for distribution.

Investing in a well-integrated **soap making machine** system, from the initial **mixing machine** through the **soap plodder** to the final **cutter**, directly impacts product quality, waste reduction, and overall profitability. Partnering with experienced manufacturers ensures access to **high efficiency flour mill plant** level reliability tailored for soap, optimizing both **bath soap making machine** outputs and industrial detergent bar production.