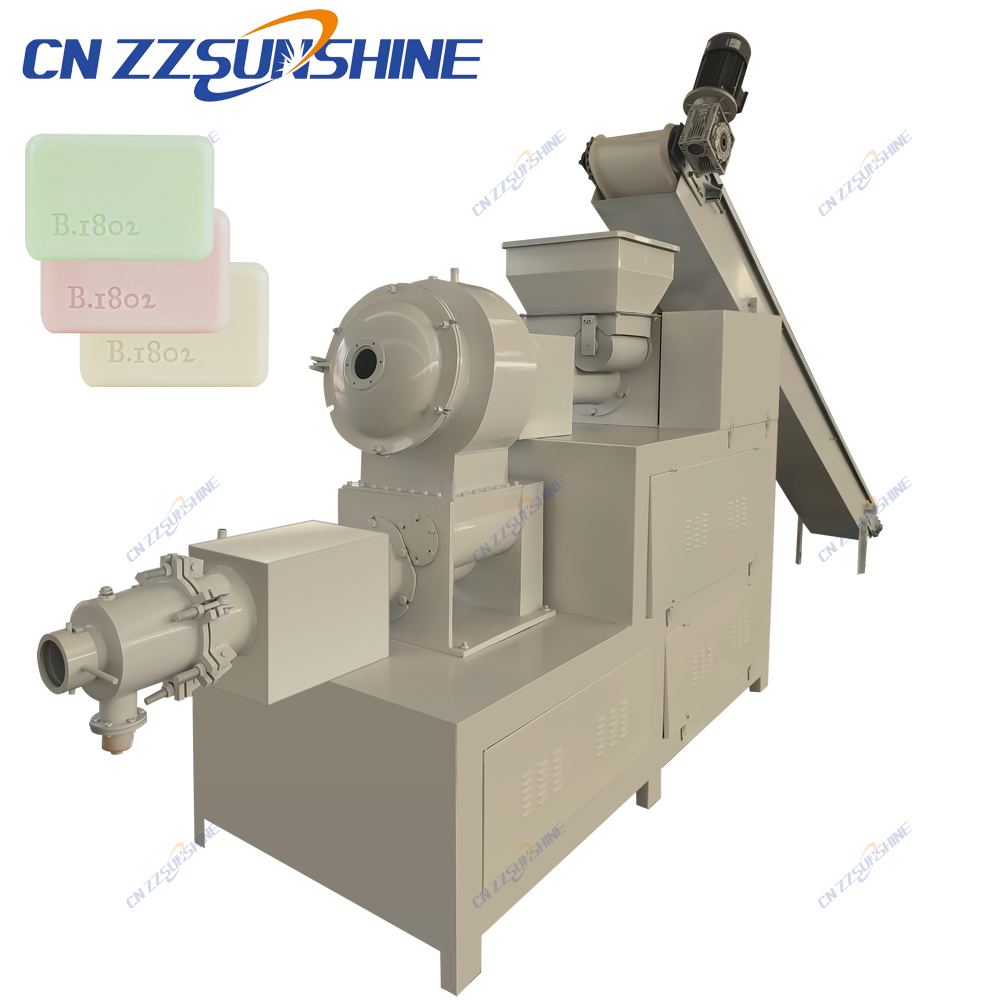

The heart of a consistent, high-quality **bar soap production line** often lies in the efficiency and sophistication of its **vacuum plodder**. This critical component is far more than just an extrusion device; it’s the stage where soap base transforms into a dense, homogeneous bar ready for cutting and finishing. Understanding its role is key for manufacturers aiming to elevate their **laundry bar soap production line** or **toilet soap finishing line**.

Modern **vacuum plodder** technology addresses core challenges in **soap making production line** operations. Before extrusion, the soap mixture, even after thorough work in the **soap mixer**, can contain trapped air pockets and variations in texture. The vacuum chamber within the plodder actively removes these air bubbles under controlled negative pressure. This deaeration is crucial. It prevents unsightly voids or “honeycombing” within the final bars, significantly improving product integrity and visual appeal. Furthermore, it enhances the **soap extrusion density**, leading to harder, longer-lasting bars that consumers prefer, whether for **laundry soap making line** or **bath soap making machine** applications.

The extrusion screw design within the **vacuum plodder** is engineered for precise molecular compaction. As the deaerated soap paste is forced through the final cone and die plate, it undergoes significant pressure. This process refines the soap’s texture, ensuring a smooth, uniform consistency throughout the entire log. This uniformity is paramount for downstream processes like **electric washing soap cutter** operation or **custom soap cutting machine** precision. Consistent log density allows for clean, accurate cuts, minimizing waste and ensuring every bar meets dimensional specifications. The resulting logs exhibit excellent structural stability, handling easily through the **automatic soap production line** stages like stamping, cooling, and wrapping.

Integrating a high-performance **vacuum plodder** into your **beauty soap making line** or industrial **soap plodder machine for bar soap** setup delivers tangible benefits: markedly reduced bar defects, improved product shelf life due to higher density, enhanced production efficiency through smoother downstream processing, and ultimately, a superior finished product. Selecting a plodder with appropriate capacity, robust construction, and precise vacuum control is an investment in the core quality and efficiency of your entire **soap making machine** operation.