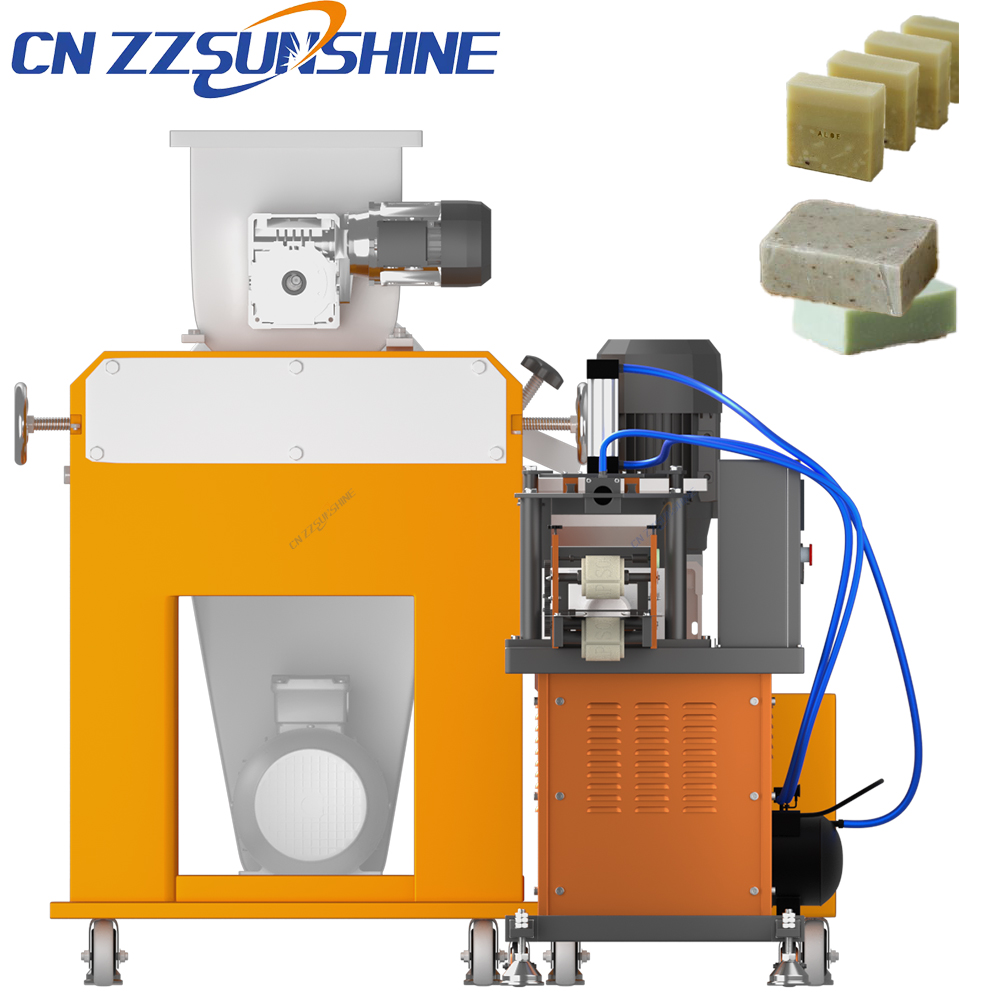

Consistent quality and efficiency are non-negotiable in modern bar soap manufacturing. The core of achieving this lies in the precision of the soap plodder machine. This critical equipment transforms mixed soap noodles into a dense, homogenous, and air-free log ready for stamping. Unlike basic extruders, industrial vacuum plodders operate under negative pressure, meticulously eliminating air pockets. This vacuum process is essential for producing hard, long-lasting bars that resist cracking and provide a smooth finish – crucial for both laundry bar soap production lines and premium toilet soap finishing lines.

Integrating the soap plodder seamlessly within a complete automatic soap production line is key. It follows the soap mixer or industrial mixer for chemical processing, where the saponified base is blended with fragrances, colors, and additives. The quality of the mixed soap base directly impacts the plodder’s efficiency. Downstream, the dense soap log requires precise cutting. Options range from robust laundry soap making line cutters to sophisticated electric washing soap cutters or custom soap cutting machines designed for intricate beauty soap making line products. The synergy between the mixer, plodder, and cutter determines output consistency and minimizes waste.

Selecting the right soap plodder machine involves several factors. Capacity must match the demands of your bath soap making machine or laundry soap operation. Vacuum strength directly correlates with final bar density and quality. Materials of construction must withstand the soap’s chemical nature. For high-volume producers, integrating a fully automatic soap production line incorporating a high-performance vacuum plodder, automated mixers, and precision cutters offers significant advantages. This setup maximizes throughput, ensures uniform product characteristics across every bar, whether for utilitarian laundry or luxurious toilet soap, and optimizes labor costs. Investing in advanced plodding technology is fundamental for any competitive soap maker aiming for superior product integrity and streamlined manufacturing efficiency.