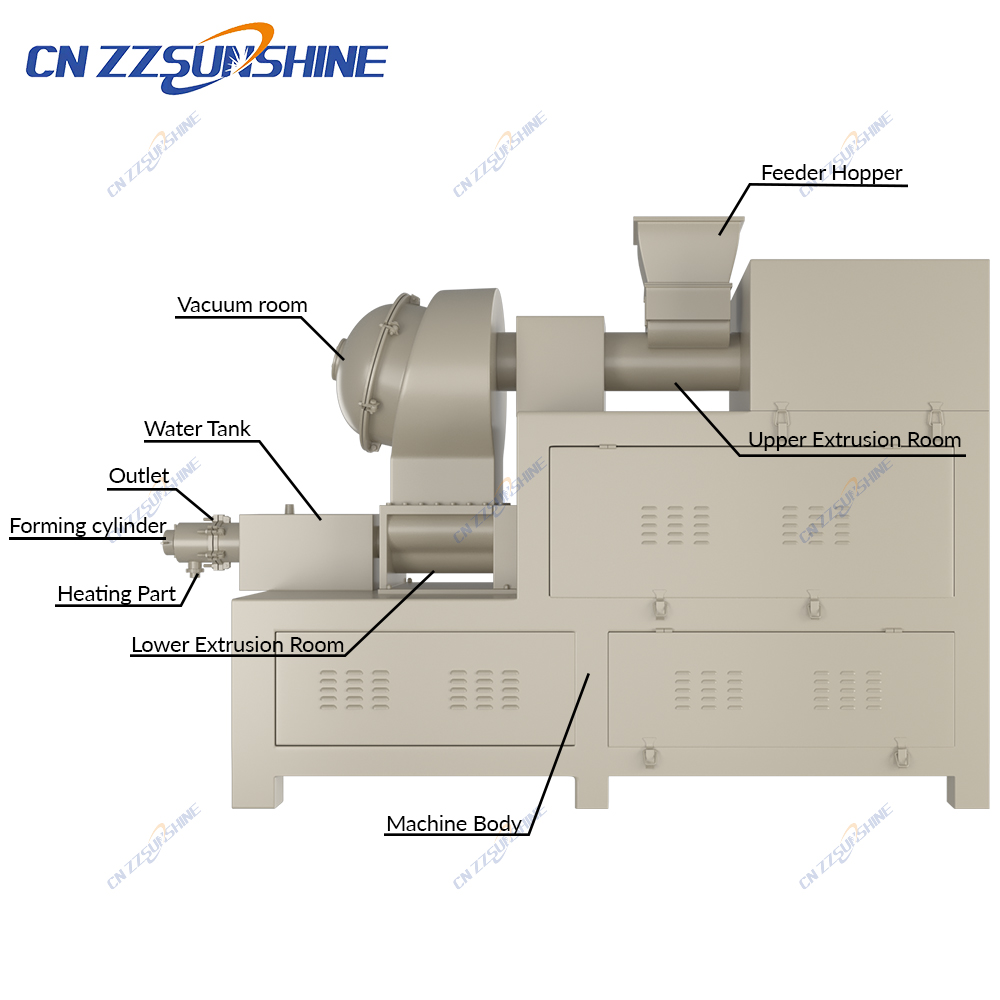

Within industrial soap making lines, achieving consistent, high-quality bar soap demands specialized equipment. The vacuum plodder machine stands as a cornerstone of modern laundry bar soap production lines and toilet soap finishing lines. Its function is critical: transforming mixed soap noodles into a dense, homogeneous, and completely deaerated log ready for stamping and cutting.

Unlike simple soap mixers that combine ingredients, the vacuum plodder performs extrusion under significant pressure and vacuum. This twin-screw or single-screw machine compresses the soap mass, forcing it through a refining screen or cone. Crucially, the integrated vacuum chamber actively removes all trapped air pockets. This deaeration is non-negotiable for producing defect-free bars; air bubbles lead to crumbling, cracking, and poor lathering characteristics in the final bath soap or laundry bar.

Integrating a high-performance vacuum plodder into your automatic soap production line directly impacts efficiency and product integrity. Key advantages include:

1. **Superior Bar Density & Hardness:** Continuous pressure extrusion creates a far denser soap log than older methods, resulting in harder, longer-lasting bars for both laundry soap making lines and beauty soap making lines.

2. **Elimination of Air Pockets:** The vacuum stage ensures a completely homogenous structure, preventing common defects like voids or “honeycombing” that plague non-deaerated soap. This is vital for premium toilet soap finishing lines.

3. **Enhanced Lathering & Smoothness:** Deaeration and intense refining yield a smoother texture and significantly improve the lathering performance of the finished bar soap.

4. **Increased Line Efficiency:** Modern vacuum plodders operate continuously, feeding downstream equipment like precision soap cutting machines or electric washing soap cutters at a steady rate, maximizing throughput for large-scale laundry bar soap production.

Choosing the right vacuum plodder involves considering factors like required capacity (single vs. twin screw), desired final bar properties, and compatibility with upstream soap mixer outputs and downstream automatic block cutter machines. For operations focused on bath soap making machine setups or demanding toilet soap finishing, investing in robust vacuum plodder technology is fundamental to achieving premium quality, efficient continuous soap production, and reliable, high-volume bar soap extrusion. The consistent output of a well-tuned plodder ensures the entire soap production line runs smoothly, delivering defect-free bars at scale.