Consistent, high-quality bar soap demands precision engineering, particularly during the extrusion phase. The soap plodder machine for bar soap is the cornerstone of any efficient laundry bar soap production line or toilet soap finishing line. This specialized equipment transforms homogenized soap noodles into a dense, continuous bar, directly impacting the final product’s texture, durability, and lather.

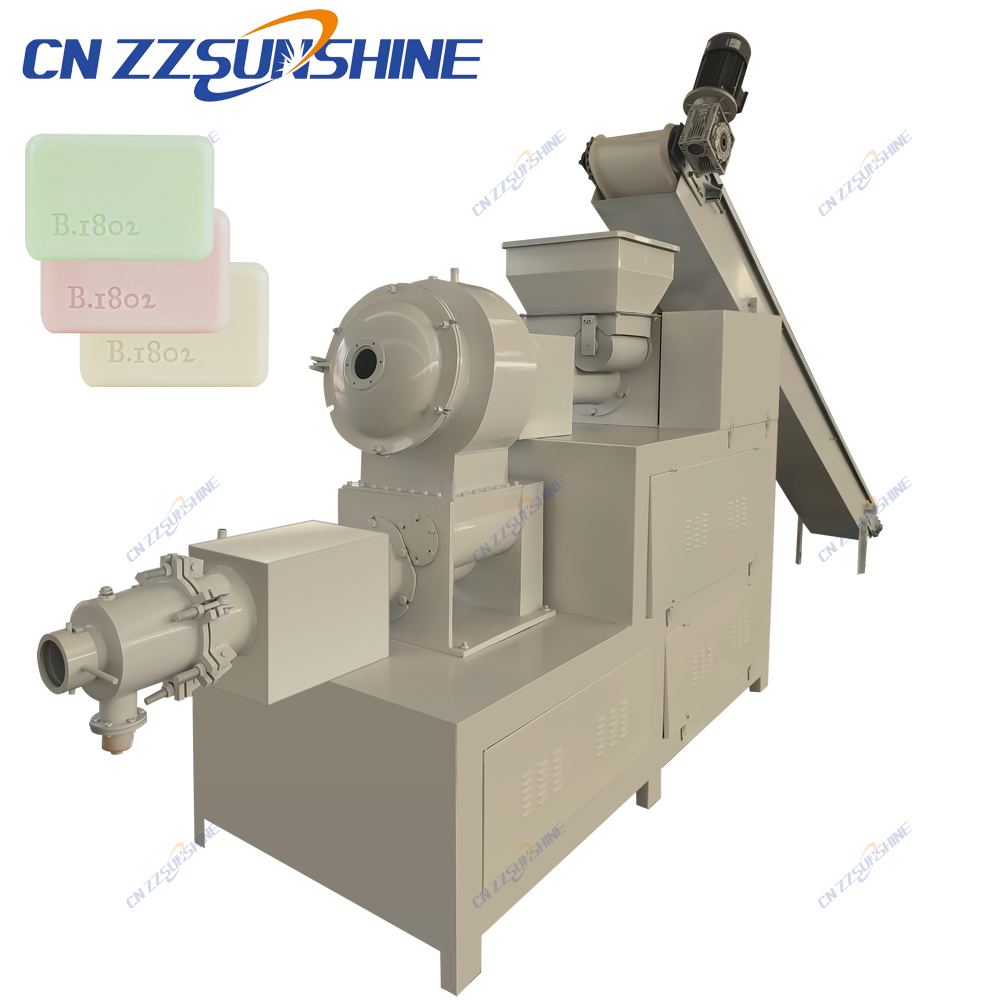

A modern vacuum plodder is essential for premium results. It subjects the mixed soap base to intense pressure within a barrel, forcing it through a tapered cone and a final die. Crucially, the integrated vacuum chamber removes trapped air during this process. This deaeration prevents unsightly bubbles and cracking in the finished bars, ensuring a smooth, professional appearance vital for both laundry and bath soap making machines. The compression also significantly enhances the bar’s hardness and longevity during use.

Integrating the plodder effectively requires compatible upstream and downstream equipment. A robust industrial mixer for chemical processing ensures the soap base (fats, lye, additives) is uniformly blended before extrusion. Downstream, an automatic soap cutting machine, often an electric washing soap cutter, slices the continuous extruded log into precise, uniform slugs or bars. This entire sequence – from the soap mixer creating the homogeneous mass, through the vacuum plodder extruding and deaerating, to the cutter forming individual units – defines a streamlined automatic soap production line.

Selecting the right soap plodder involves evaluating factors like throughput capacity, vacuum efficiency, and compression ratio. For large-scale operations, such as a complete laundry soap making line or beauty soap making line, a high-output, double-stage vacuum plodder is often the optimal choice. It guarantees the density and air-free structure required for mass-market products. Properly maintained plodder machines deliver exceptional reliability, minimize waste, and are fundamental for manufacturers aiming for consistent quality and optimal efficiency in competitive bar soap markets.