Consistent density and texture are non-negotiable in quality bar soap production, whether for laundry or toiletries. Achieving this efficiently at scale hinges on the industrial soap plodder machine, the core extrusion unit within any modern laundry bar soap production line or toilet soap finishing line. Unlike simple compactors, a properly engineered plodder, particularly a vacuum plodder, actively removes air pockets during the extrusion process. This vacuum function is essential for producing hard, long-lasting bars that resist cracking or crumbling during use and packaging.

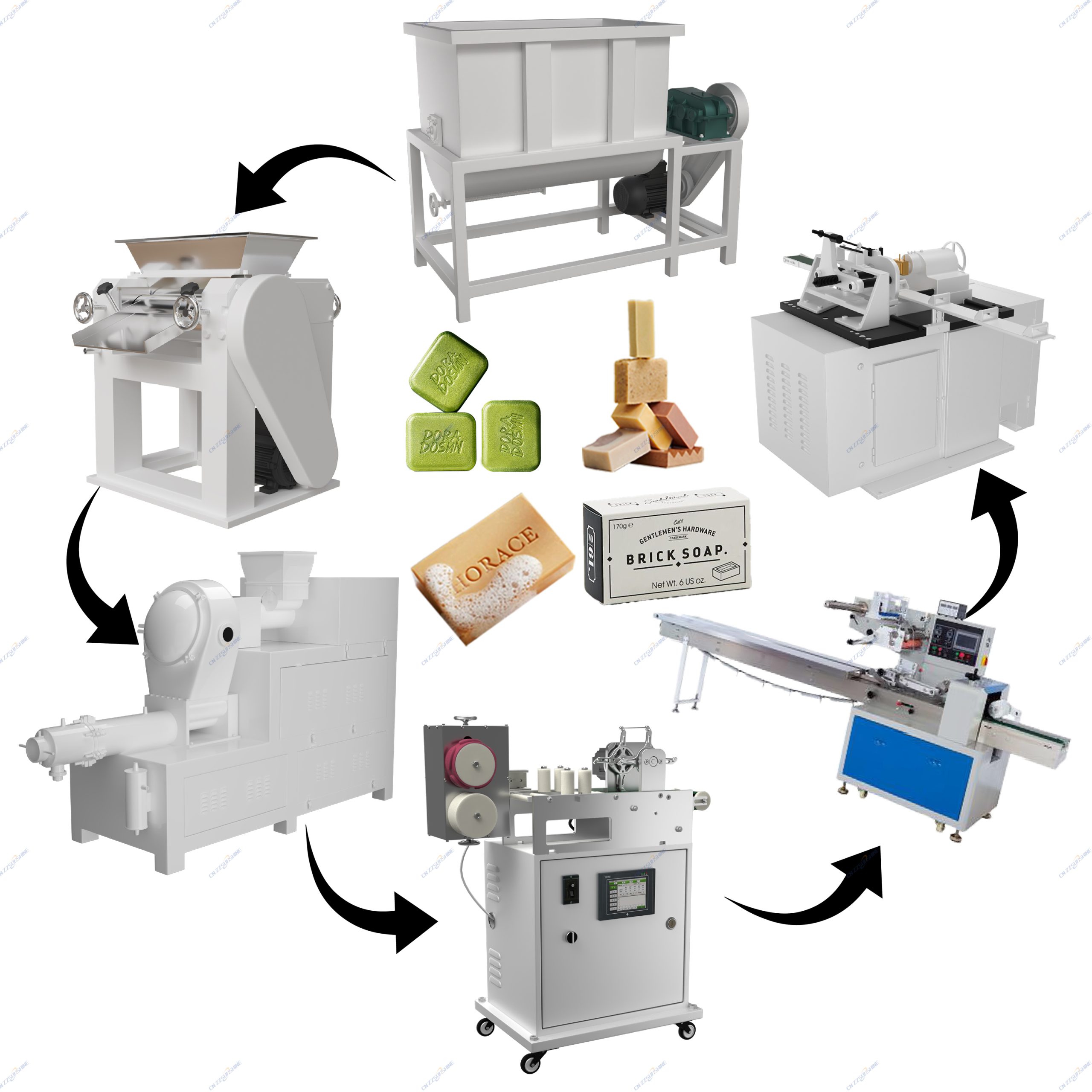

Integrating the soap plodder machine seamlessly into an automatic soap production line demands compatibility with upstream and downstream equipment. The mixed soap base from a heavy-duty soap mixer – often a robust twin-shaft industrial mixer for chemical processing – must feed consistently into the plodder hopper. Downstream, precision cutting is vital. While traditional cutter units exist, modern lines often utilize high-speed electric washing soap cutters or custom soap cutting machines for accurate, hygienic sizing with minimal waste, especially critical in bath soap making machines and beauty soap making lines.

The choice between a single-stage vacuum plodder and a more complex twin-stage vacuum plodder impacts final product quality and line throughput. Twin-stage units offer superior de-aeration and homogenization, essential for premium toilet soap finishing lines where smoothness and luxurious feel are paramount. Operators report significant improvements in bar density consistency (often 15-20%) and reduced lather inhibitors when implementing vacuum plodding versus non-vacuum methods. This directly translates to consumer satisfaction and brand reputation.

For manufacturers evaluating a laundry soap making line or upgrading an existing bath soap making machine setup, partnering with experienced suppliers who understand the interplay between the soap mixer, vacuum plodder, and cutter is crucial. Look for OEM providers offering robust construction, readily available wear parts, and process expertise. Optimizing the extrusion stage via the industrial soap plodder machine remains the most effective strategy for boosting yield, enhancing bar quality, and ensuring the smooth operation of the entire automatic soap production line.