Unlock Your Soap Production Potential: Smart Machines for Every Budget

Dreaming of launching your own soap brand or scaling up production? The right equipment is crucial, but navigating the world of soap making machinery can feel overwhelming, especially with budget constraints. The good news? You don’t need a massive investment to start producing high-quality bars efficiently. Modern soap making production lines are more accessible than ever, offering incredible value and functionality tailored for businesses of all sizes, from hobbyists turning pro to established manufacturers seeking compact solutions.

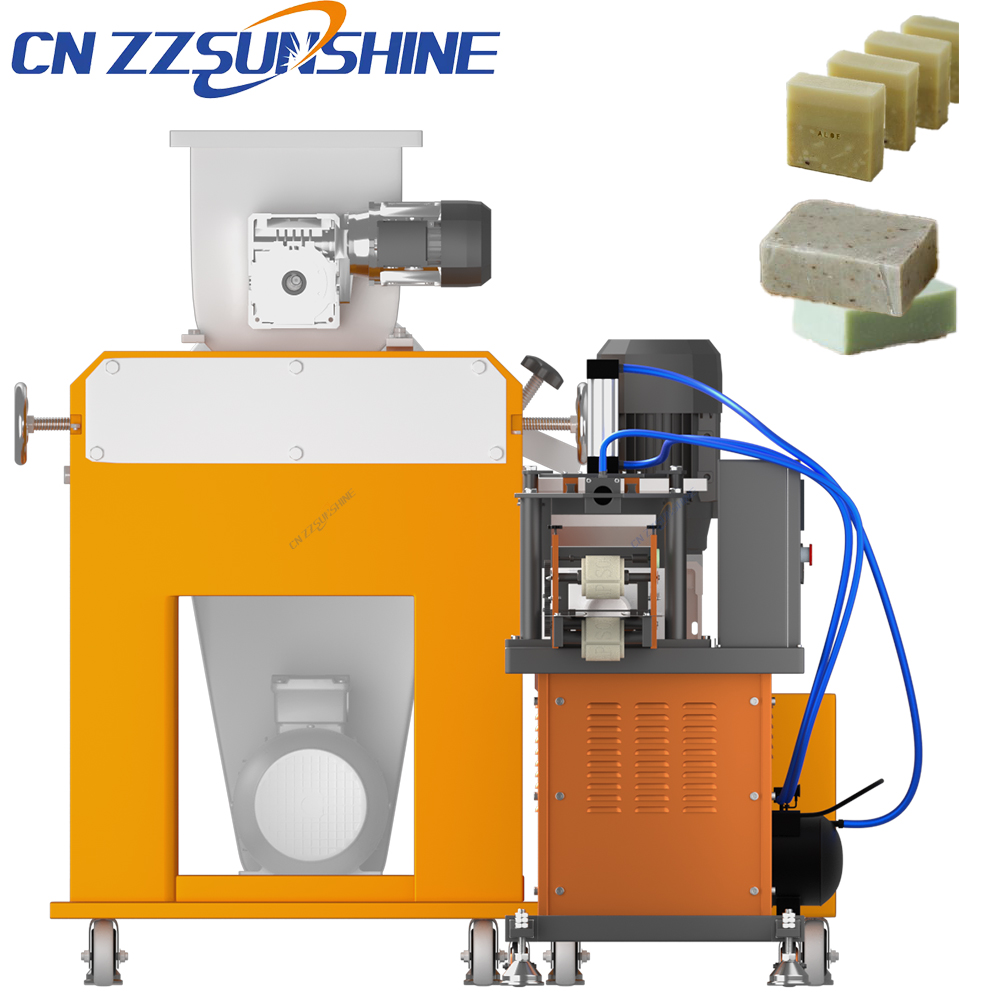

For those starting out or operating on a smaller scale, a focused soap machine small making setup is the perfect entry point. Think of it as your core toolkit. Essential components like a robust soap mixer ensure a perfectly homogeneous mix of oils, lye, and additives – the foundation of a great bar. Following mixing, a soap plodder machine for bar soap, particularly a compact Vacuum plodder, becomes indispensable. It removes air bubbles and compresses the soap mass into a continuous, dense extrusion (or log), critical for achieving that professional finish and consistent bar soap production line output. Even smaller setups benefit immensely from this step.

Next comes shaping and branding your product. For cutting those extruded logs into individual bars, options abound. A reliable custom soap cutting machine or an Electric washing soap cutter provides precise, clean cuts without the strain of manual methods. Depending on your volume, you might consider Manual Cutting Machine, Electronic Cutting Machine, or Pneumatic Cutting Machine variants. Then, add your unique touch with a Soap Stamping Machine – even a Semi-automatic Printer or Automatic Printer allows for efficient logo application, making your bars stand out on shelves. Finally, a simple Film Packaging Machine protects your finished product.

This streamlined approach forms the heart of many successful Mini Soap Production Lines or Semi-automatic soap production line setups. It delivers professional results without the complexity or cost of larger, fully automated systems. You gain control over production, maintain quality, and keep overheads manageable. Whether you’re targeting the laundry soap making line market with sturdy bars or crafting luxurious beauty soap making line products, the right small-scale equipment is your launchpad.

The key is finding a supplier who understands diverse needs and offers Operation Soap Maker Machine With Cheap Price without compromising on essential functionality. Look for manufacturers providing core machines like compact soap plodders and soap mixers, along with cutter options and stamping solutions, often with OEM flexibility. Investing in a well-designed Automatic soap production line core, even on a smaller scale, empowers you to produce consistently excellent soap efficiently and cost-effectively, turning your soap-making vision into a thriving reality.