Revolutionize Your Soap Production: Introducing the Compact, High-Quality Solution

For many artisanal producers and small-scale manufacturers, scaling soap production while maintaining quality presents significant challenges. Manual processes are labor-intensive and inconsistent, while large industrial lines are prohibitively expensive and space-consuming. This gap in the market demands a solution that blends efficiency, quality, and affordability – a need perfectly met by our innovative small soap production line, centered around the New High Quality Bar Soap Noodles Mixer/Deep Clean Laundry Bar Soap Making Machine.

The Heart of Quality: Superior Mixing and Refining

Consistent, high-grade soap starts with impeccable mixing and refining. Our compact line integrates a high-quality bar soap noodles mixer designed for thorough blending of raw materials, essential oils, pigments, and additives. This mixing machine ensures a homogenous paste, crucial for achieving uniform color, scent, and texture in every bar, whether it’s for laundry bar soap production or delicate beauty soap making.

Following mixing, achieving the perfect soap texture requires precision. Our system incorporates a three roller grinding mill (available for OEM customization) that refines the soap mass, smoothing out any inconsistencies and creating a dense, workable paste ready for extrusion. This step is vital for producing bars that feel luxurious and lather effectively.

Precision Extrusion and Cutting: The Key to Uniform Bars

Transforming the refined soap paste into bars requires controlled extrusion and cutting. Our line features a robust soap plodder machine for bar soap, specifically a vacuum plodder. This component is critical as it compresses the soap under vacuum conditions, removing trapped air pockets that can cause crumbling or cracking in the final product. The result is a continuous, dense, and smooth soap log.

The extruded log then moves to the cutting stage. An automatic block cutter machine slices the log into precise, uniform blocks. Options include pneumatic cutting machines for consistent force application or electronic cutting machines for programmable precision. This eliminates the variability and physical strain associated with manual cutting machines, ensuring every bar meets exact specifications. For specialized shapes, a custom soap cutting machine can be integrated.

Finishing Touches: Stamping and Packaging

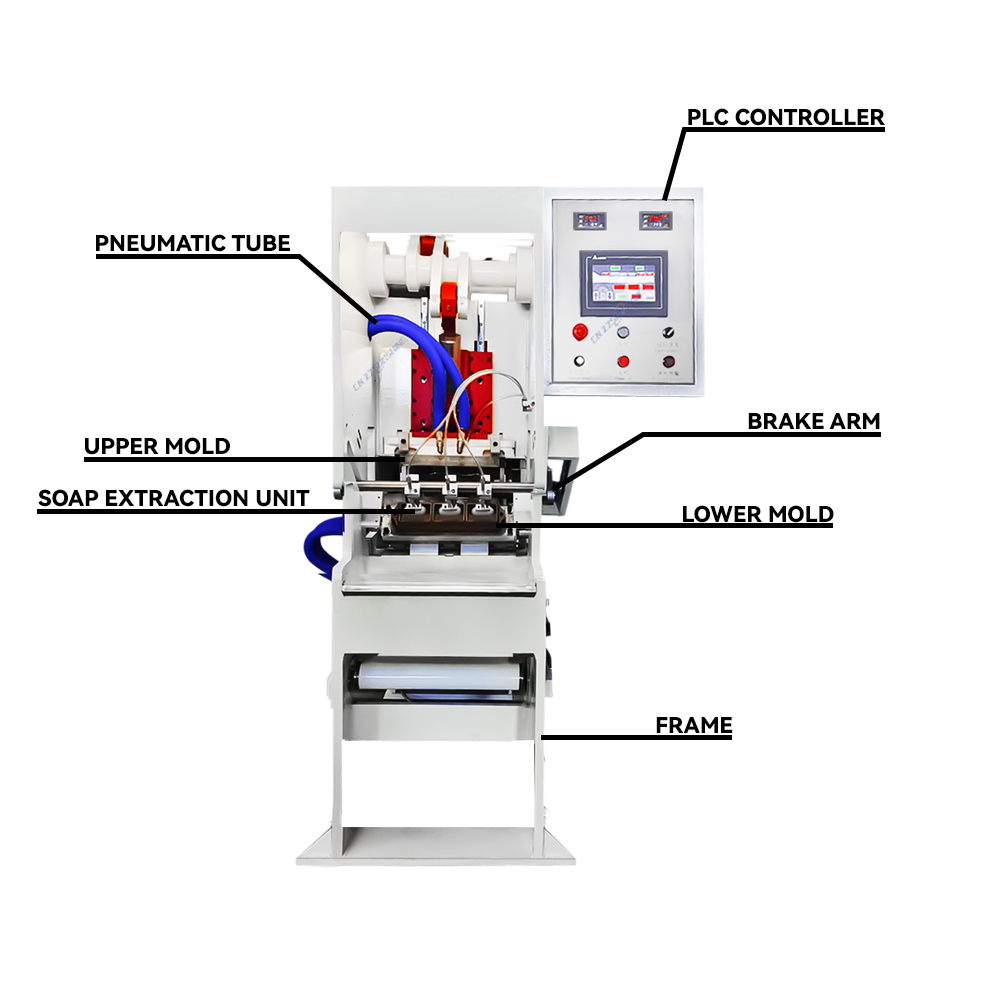

The final stages transform the soap blocks into finished products ready for market. A soap stamping machine imprints logos, designs, or text onto each bar, adding brand identity and a professional touch. For toilet soap finishing lines or premium bath soap making machines, this step is particularly important for aesthetic appeal.

Finally, a film packaging machine efficiently wraps and seals the finished bars, protecting them from moisture, dirt, and damage during storage and transport. This automated packaging ensures product integrity and extends shelf life.

Why Choose Our Compact Line?

This automatic soap production line, while designed for smaller scale operations, delivers results rivaling larger systems. It integrates seamlessly:

High-Quality Mixing: Essential for deep clean laundry bar soap and delicate beauty bars.

Vacuum Plodding: For dense, air-free bars.

Precision Cutting: Via automatic block cutter machines.

Efficient Finishing: With soap stamping machines and film packaging machines.

Whether you’re establishing a dedicated laundry soap making line, a beauty soap making line, or producing versatile bar soaps, this semi-automatic printer equipped line offers the perfect blend of automation and control. It significantly reduces labor costs, minimizes waste through precision, and guarantees consistent, high-quality output batch after batch.

Empower Your Production Today

Don’t let inefficient processes limit your soap business’s growth and potential. Our small soap production line, featuring the core New High Quality Bar Soap Noodles Mixer/Deep Clean Laundry Bar Soap Making Machine, provides the technological edge you need. Experience the difference that professional-grade, yet accessible, soap making machinery can make. Contact us today to discuss how we can tailor this automatic soap production line to your specific needs and help you elevate your soap production to new heights of quality and efficiency. Request a quote and explore customization options!