Craft Your Success: Why Compact Soap Machines are Revolutionizing Small-Scale Production

The demand for unique, handcrafted soaps is booming. From artisan boutiques to bespoke gift lines, consumers are seeking quality and individuality. For entrepreneurs and small businesses, this presents a golden opportunity. But scaling production without sacrificing quality or breaking the bank can be daunting. Enter the new generation of small-scale soap making equipment – compact, efficient, and surprisingly powerful.

Unlocking Potential with the Right Tools

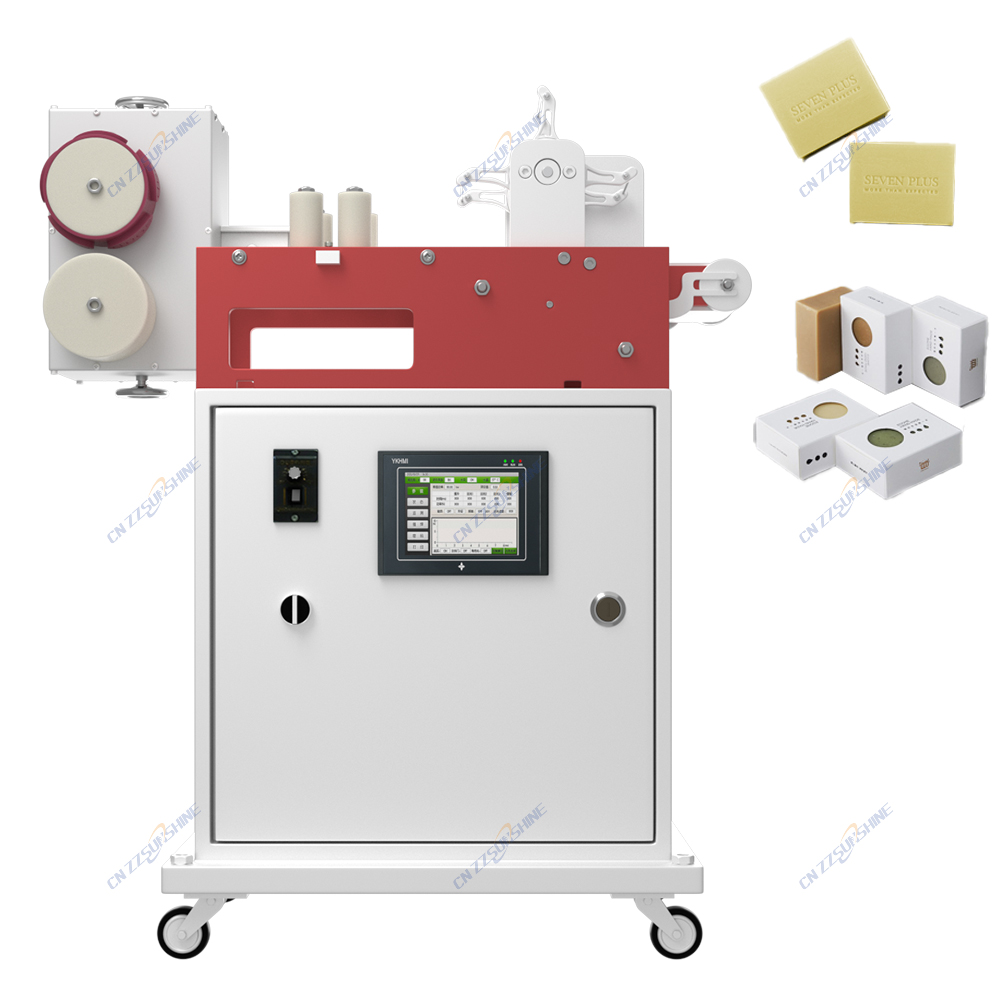

Gone are the days when starting a soap line required massive investment in industrial-scale machinery. Today’s hot selling small soap equipment is designed specifically for smaller batches and limited space. These mini soap production line solutions are engineered for efficiency, allowing you to produce consistent, professional-grade bars without the footprint or complexity of larger systems. The new best sale small scale soap making home machine isn’t just a gadget; it’s a gateway to serious business potential.

Essential Components for Quality Bar Soap

So what makes up an effective small-scale setup? Key components often include:

Soap Mixer/Mixing Machine: Ensures thorough blending of ingredients for uniform texture and properties.

Soap Plodder Machine: A crucial element, especially a vacuum plodder for smaller setups, which compacts the mixed soap base, removes air pockets, and extrudes a solid, homogenous log. This step is vital for achieving a smooth, long-lasting bar.

Cutting Solutions: Depending on needs, options range from manual cutting machines to more advanced automatic block cutter machines or pneumatic cutting machines. Electric washing soap cutters or electronic cutting machines offer precision slicing for consistent bar sizes.

Finishing Touches: While large soap stamping machines exist, smaller operations might utilize semi-automatic printers for branding. Even simple film packaging machines add a professional touch.

Why Choose Compact Equipment?

Investing in a focused soap making machine setup offers distinct advantages:

1. Affordability: Significantly lower upfront costs compared to full automatic soap production line systems.

2. Flexibility: Easily adapt recipes and production volumes. Perfect for testing new designs or seasonal lines.

3. Quality Control: Maintain hands-on oversight for exceptional quality in every bar, whether it’s a delicate beauty soap making line or robust laundry bar soap production line.

4. Efficiency: Streamline your process. A well-chosen soap plodder combined with a reliable cutter drastically reduces manual labor and time per batch.

5. Customization: Many suppliers offer custom soap cutting machine options or OEM three roller grinding mill services to tailor equipment to specific needs.

Building Your Dream, One Bar at a Time

For passionate soap makers looking to turn their craft into a thriving business, efficient small-scale machinery is no longer a luxury – it’s a necessity. These hot selling small soap equipment packages provide the practical foundation needed to scale intelligently. They empower you to meet growing demand, ensure consistent product excellence, and carve out a profitable niche in the competitive soap market. Explore the possibilities and discover how the right mini soap production line can be the cornerstone of your entrepreneurial success.