The Mighty Mini: Streamlining Soap Finishing with Compact Roller Grinders

For businesses crafting high-quality toilet soaps, bath bars, or specialty beauty soaps, achieving that perfect, smooth finish is paramount. While large-scale operations often dominate the conversation, the need for efficient, space-saving solutions is growing, especially for boutique hotels, smaller manufacturers, or those starting their soap-making journey. Enter the compact yet powerful Mini Soap Grinder Grinding Machine – the Automatic Soap Milling Roller Machine designed to deliver professional results without demanding a massive footprint.

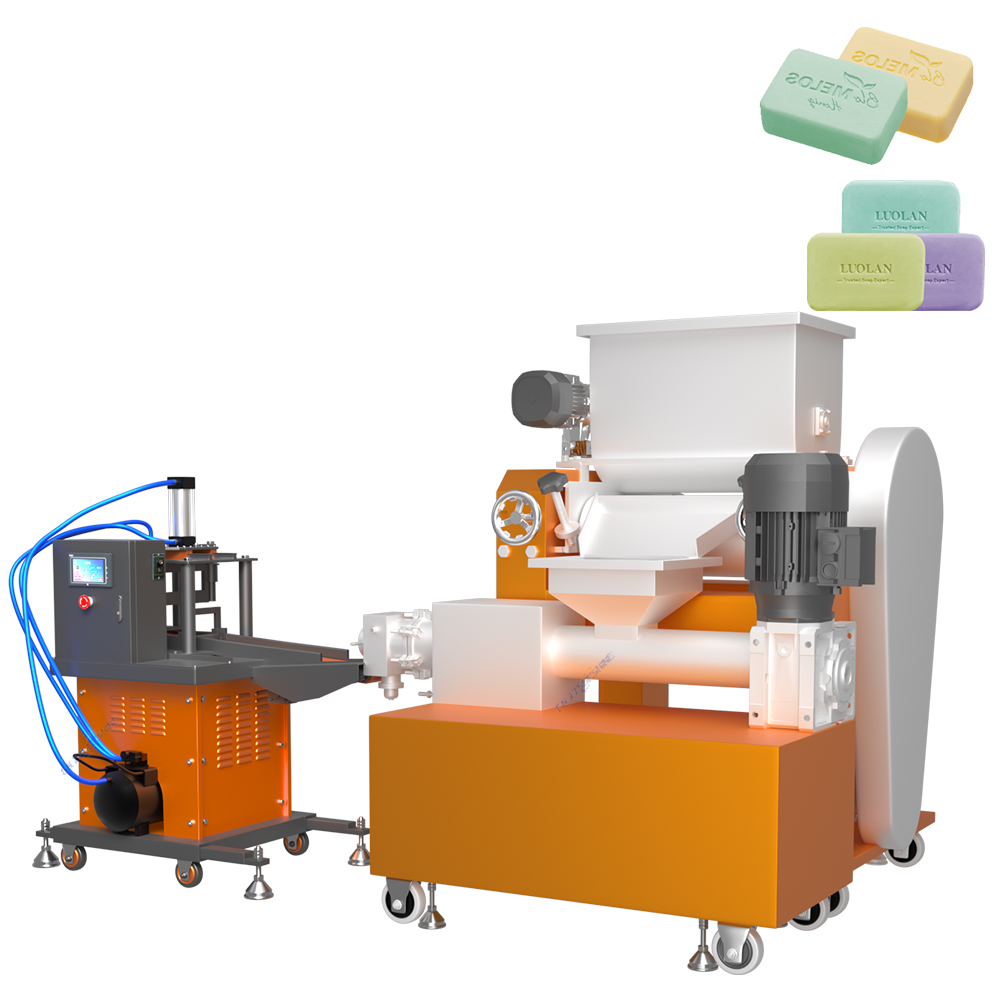

This specialized piece of equipment focuses on a critical stage: refining the soap base. Following extrusion through a soap plodder machine and cutting with an automatic block cutter machine, the soap noodles or logs often require milling to ensure a homogenous texture and remove imperfections. This is where the roller mill shines. Using the principle of OEM three roller grinding mill technology in a smaller form factor, it meticulously grinds the soap, creating a smooth, pliable paste ready for the final plodding and stamping stages.

Integrating a Mini Soap Grinding Machine into your soap making production line offers significant advantages. Its compact size makes it ideal for Mini Soap Production Lines or supplementing existing setups where space is limited, such as in hotel amenities production or small-scale beauty soap making lines. Automation features reduce manual handling, ensuring consistent output quality crucial for brand reputation. The refined soap paste it produces feeds seamlessly into downstream equipment like a Vacuum plodder and Soap Stamping Machine, guaranteeing bars with an impeccable feel and appearance.

Whether you’re running a dedicated toilet soap finishing line, a laundry bar soap production line, or a versatile bath soap making machine setup, incorporating a purpose-built roller grinder is a smart investment. It enhances the efficiency of your Automatic soap production line, improves product quality, and allows smaller operations to achieve professional-grade soap finishing, proving that mighty results can indeed come in small packages. Explore how this essential component can elevate your soap crafting process.