Optimizing Your Soap Manufacturing: From Saponification to Finished Bar

For manufacturers seeking robust, industrial used soap making machine solutions, understanding the core processes is key. The journey begins with the Manufacturer soap saponification machine, the critical unit where fats and alkalis react under controlled conditions to form soap base. This stage sets the foundation for quality.

Efficient production hinges on seamless integration. A Full automatic laundry soap making small line exemplifies this, incorporating advanced components like a soap plodder machine for bar soap to homogenize and extrude the paste, followed by precise cutting equipment. Modern lines often feature automatic block cutter machine units or custom soap cutting machine options (Electric washing soap cutter, Pneumatic Cutting Machine) to achieve consistent bar sizes with minimal waste.

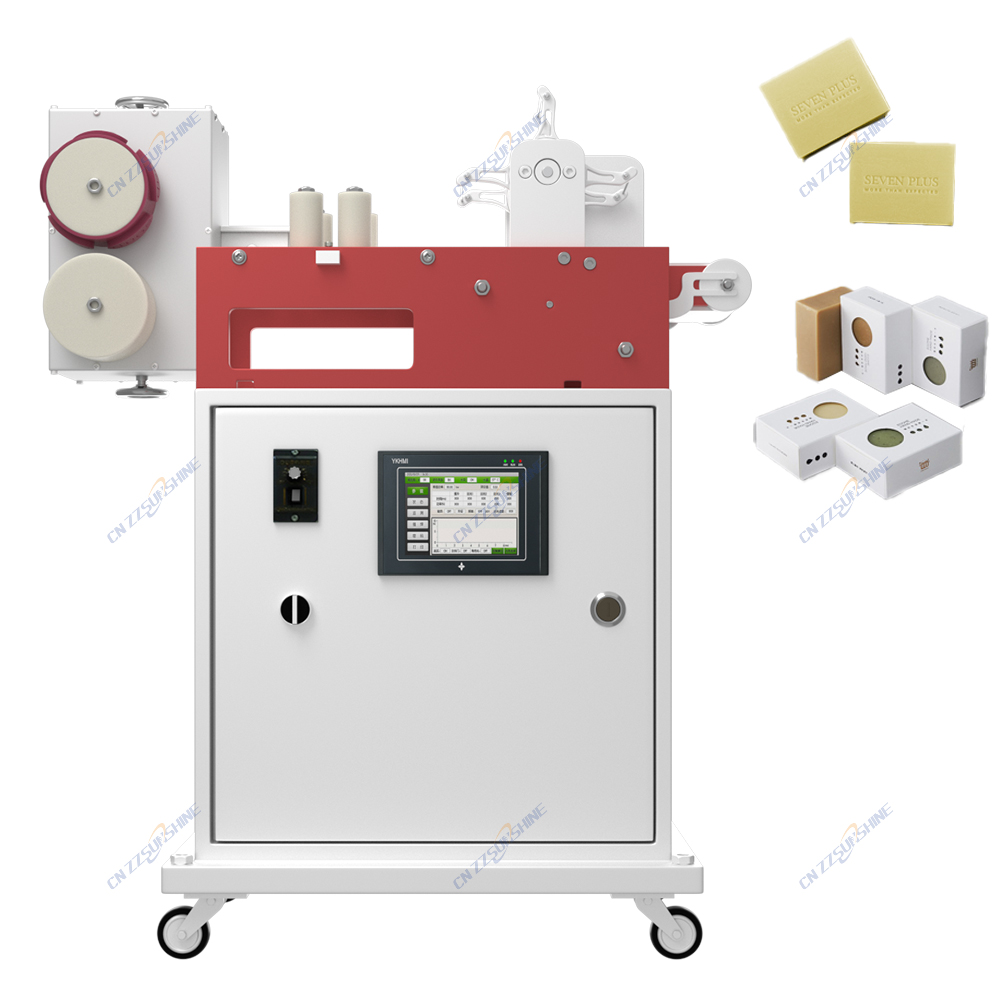

Beyond laundry bars, similar principles apply to toilet soap finishing line or beauty soap making line operations. Key equipment like the Vacuum plodder ensures dense texture, while OEM three roller grinding mill units refine the soap for premium finishes. Downstream, Automatic Printer and Soap Stamping Machine units brand the final product before Film Packaging Machine secures it.

Whether investing in a complete Automatic soap production line or a Mini soap production line, selecting reliable machinery – from the essential soap mixer and Mixing machine to the final cutter – streamlines production, enhances product consistency, and boosts overall output for laundry or toilet soap applications.