Unlock Efficiency: Your Guide to Modern Soap Making Machinery

The soap industry thrives on quality and efficiency. Whether crafting luxurious beauty bars, robust laundry soaps, or specialty products, the right soap making production line is paramount. Modern soap making machine technology elevates production from artisanal batches to high-volume outputs while maintaining superior quality. This guide explores key equipment, focusing on core components like the soap plodder machine for bar soap and essential finishing tools such as the high quality bar soap cutting machine cutter.

The Heart of Production: Mixing, Refining, and Extrusion

Every great bar starts with a well-mixed paste. A reliable soap mixer (or mixing machine) ensures uniform blending of fats, oils, lye, and additives. For achieving the desired smoothness and texture, refining mills are crucial. An OEM three roller grinding mill provides exceptional shearing action, refining the soap mass to eliminate grit and create a homogenous blend before extrusion.

The extrusion stage is where the soap base truly takes shape. The soap plodder, particularly a vacuum plodder, is a cornerstone of both laundry soap making line and toilet soap finishing line operations. This machine compacts the refined soap under vacuum conditions, removing trapped air that could cause imperfections. It then extrudes a continuous, dense log of soap, ready for the next stages. This extrusion is vital for producing bars with consistent density and a smooth finish, whether for a large-scale automatic soap production line or a more compact mini soap production line.

Precision Cutting: From Log to Bar

The extruded soap log must be precisely cut into individual bars. This is where cutting machines become indispensable. Moving beyond basic manual cutting machine options, automated solutions offer significant advantages in speed, consistency, and safety.

An automatic block cutter machine is engineered for high-volume production. It slices the soap log into uniform blocks or billets with minimal waste. For operations requiring flexibility or smaller batches, options like a pneumatic cutting machine or electronic cutting machine provide excellent precision with user-friendly operation. The choice between an electric washing soap cutter or other variants often depends on the specific soap type (e.g., hard laundry bars vs. softer beauty soaps) and the desired output volume. A custom soap cutting machine can also be developed to meet unique size or shape requirements.

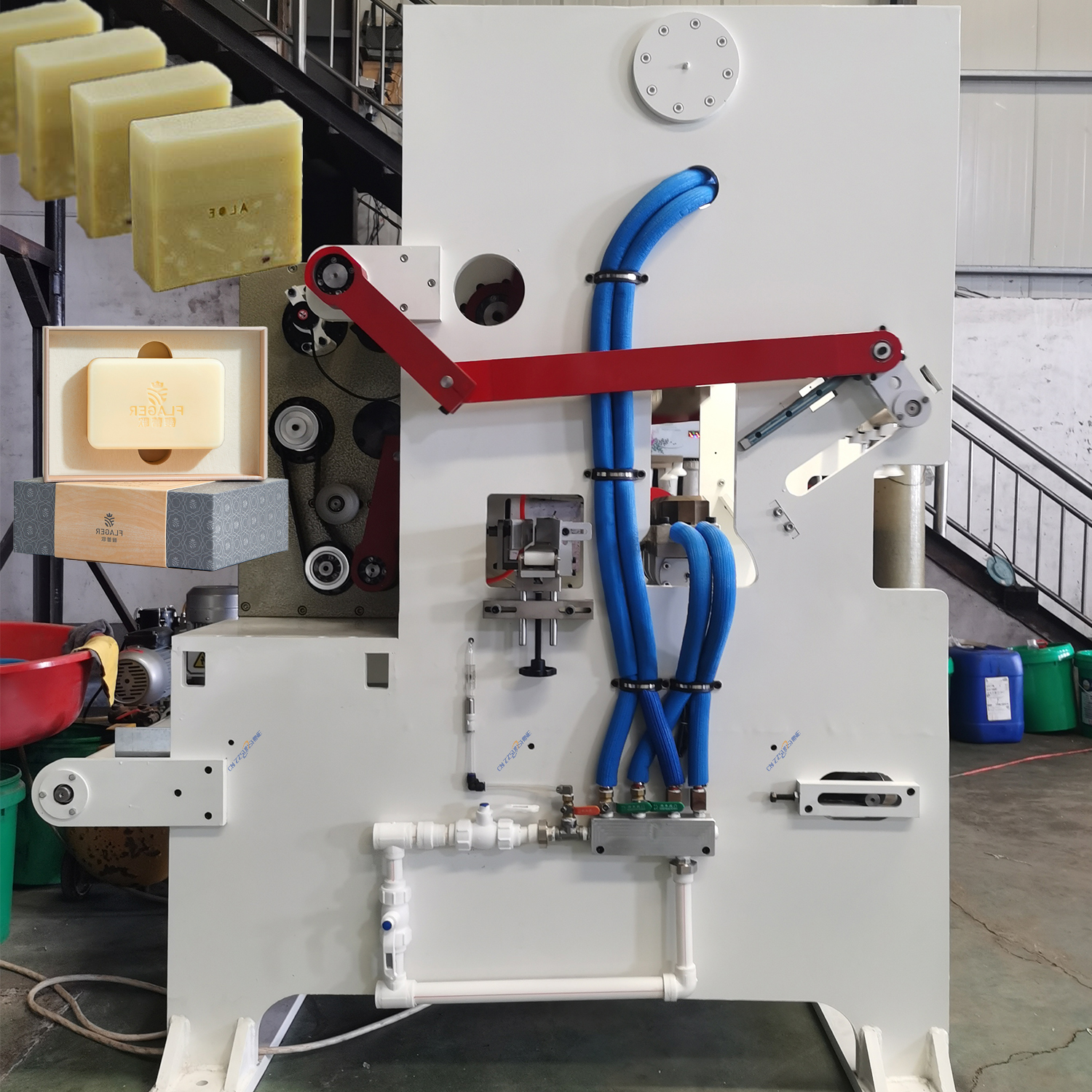

Finishing Touches: Stamping and Packaging

After cutting, bars typically undergo stamping and packaging. A soap stamping machine imprints logos, brand names, or designs onto the bar surface. Automation levels vary, from semi-automatic printer units requiring manual bar feeding to fully automatic printer systems integrated seamlessly into the line.

Finally, protecting the finished product is key. A film packaging machine efficiently wraps individual bars or groups in protective film, ensuring hygiene and presentation during storage and transport. This completes the journey within a comprehensive laundry bar soap production line or a specialized beauty soap making line.

Choosing the Right Equipment for Your Needs

Selecting the optimal soap making plant involves assessing your production goals (volume, soap types), available space, and budget. Key considerations include:

Scale: A mini soap production line might suffice for startups, while established brands benefit from a full automatic soap production line.

Automation Level: Balance between manual intervention and full automation impacts labor costs and throughput.

Soap Type: Equipment specifications (like plodder pressure or cutter blade type) vary for bath soap making machine setups versus washing liquid production equipment.

Customization: Custom soap cutting machine solutions or tailored mill configurations can address unique formulations or bar shapes.

Investing in high-quality machinery – from the essential soap plodder and cutter to refinishing mills and packaging units – is an investment in product consistency, operational efficiency, and brand reputation. By understanding the roles of each component, manufacturers can build or upgrade their soap making production line to achieve superior results.