Crafting Quality Soap Efficiently: Your Path to Affordable Production

Entering the soap manufacturing market or scaling your existing operation demands reliable, cost-effective equipment without compromising on quality. Finding machinery that balances performance, affordability, and customization is key. This is where solutions like our Low Price Bath Soap Making Machine, Cheap Laundry Soap Machine, and customizable Face Soap Making Production Line come into play, designed to empower businesses of all sizes.

Whether you’re producing luxurious bath soap, robust laundry bar soap, or specialized beauty soap, a streamlined production process is essential. Modern soap making production lines integrate various specialized machines to handle each stage efficiently, from raw material preparation to finished, packaged bars. Key components include:

Mixing & Refining: A robust soap mixer or mixing machine ensures homogeneous blending of fats, oils, alkalis, and additives. For finer texture, especially in high-quality toilet or facial soaps, an OEM three roller grinding mill is indispensable for refining the soap paste.

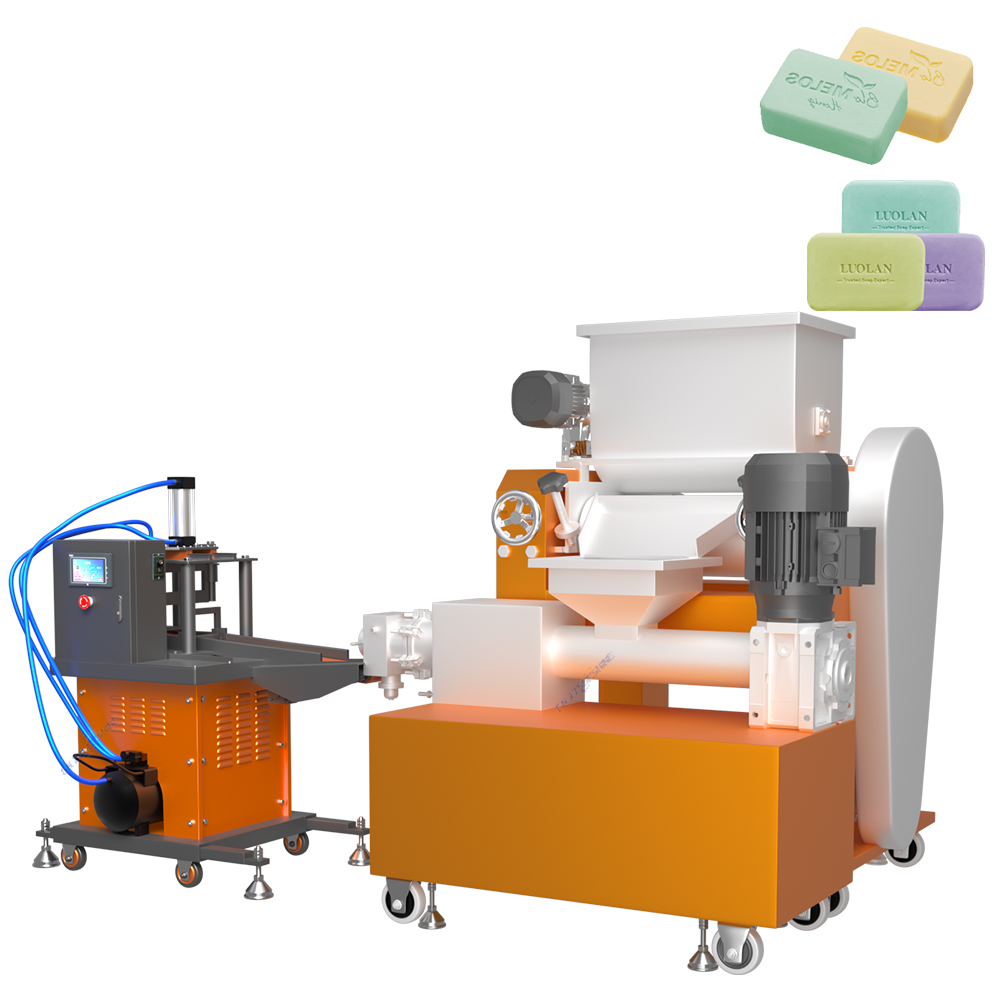

Extrusion & Shaping: The heart of bar soap production lies in the soap plodder. A vacuum plodder is crucial, as it removes air pockets, resulting in a denser, smoother bar with superior lather and longevity. This step is vital for both toilet soap finishing lines and laundry bar soap production lines.

Cutting: Precision cutting transforms continuous soap extruders into individual bars. Options range from manual cutting machines for smaller batches to automatic block cutter machines for high-volume output. Electric washing soap cutters, pneumatic cutting machines, or electronic cutting machines offer varying levels of automation and precision for different needs and budgets. A custom soap cutting machine ensures your bars meet exact size specifications.

Stamping & Packaging: Branding is achieved with a soap stamping machine, imprinting logos or designs. Finally, a film packaging machine protects the finished soap, whether for individual bars or multipacks.

For businesses seeking automation, a comprehensive automatic soap production line integrates these components seamlessly, minimizing labor and maximizing consistency. Conversely, a mini soap production line or semi-automatic setups (featuring components like a semi-automatic printer or manual cutting machine) offer excellent entry points or solutions for niche products.

Why Choose Our Solutions?

Our focus is on delivering soap making machines and production lines that offer exceptional value. We understand that “low cost” should never mean “low quality.” Our machinery, including the essential soap plodder machine for bar soap, is engineered for durability and consistent performance. Crucially, we offer extensive customization – not just in machinery configuration (custom soap cutting machine, specific soap plodder setups) but also enabling you to add your customized logo directly onto the bars using integrated stamping or dedicated automatic printer units. This transforms your production line into a powerful branding tool.

Embrace Efficiency & Brand Identity

Investing in the right soap making machine or complete line – be it for laundry soap making, bath soap production, or specialized beauty soap – is an investment in your brand’s future. Our affordable, reliable, and customizable solutions, from individual machines like the OEM three roller grinding mill to turnkey automatic soap production lines, are designed to help you produce excellent soap efficiently while proudly displaying your customized logo. Explore how our cheap laundry soap machine or low price bath soap making machine can elevate your production today. Let us help you turn your brand vision into tangible products.