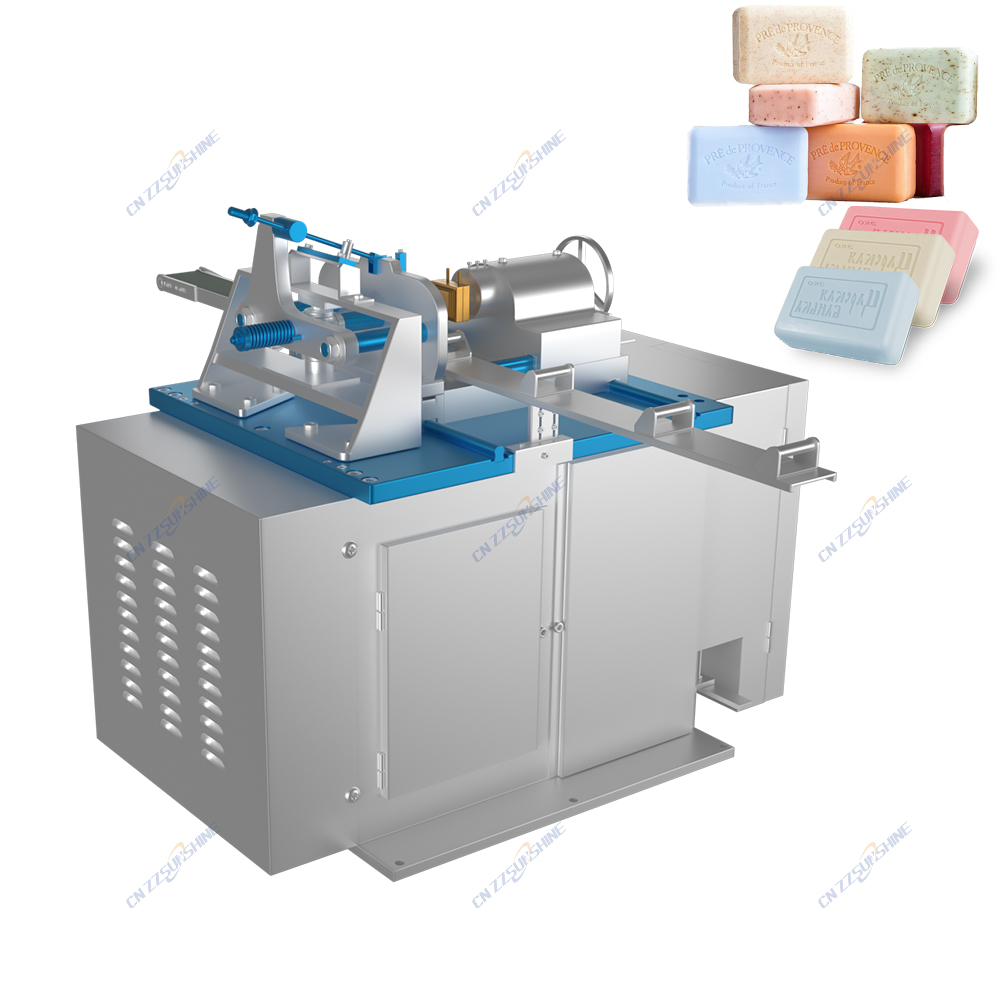

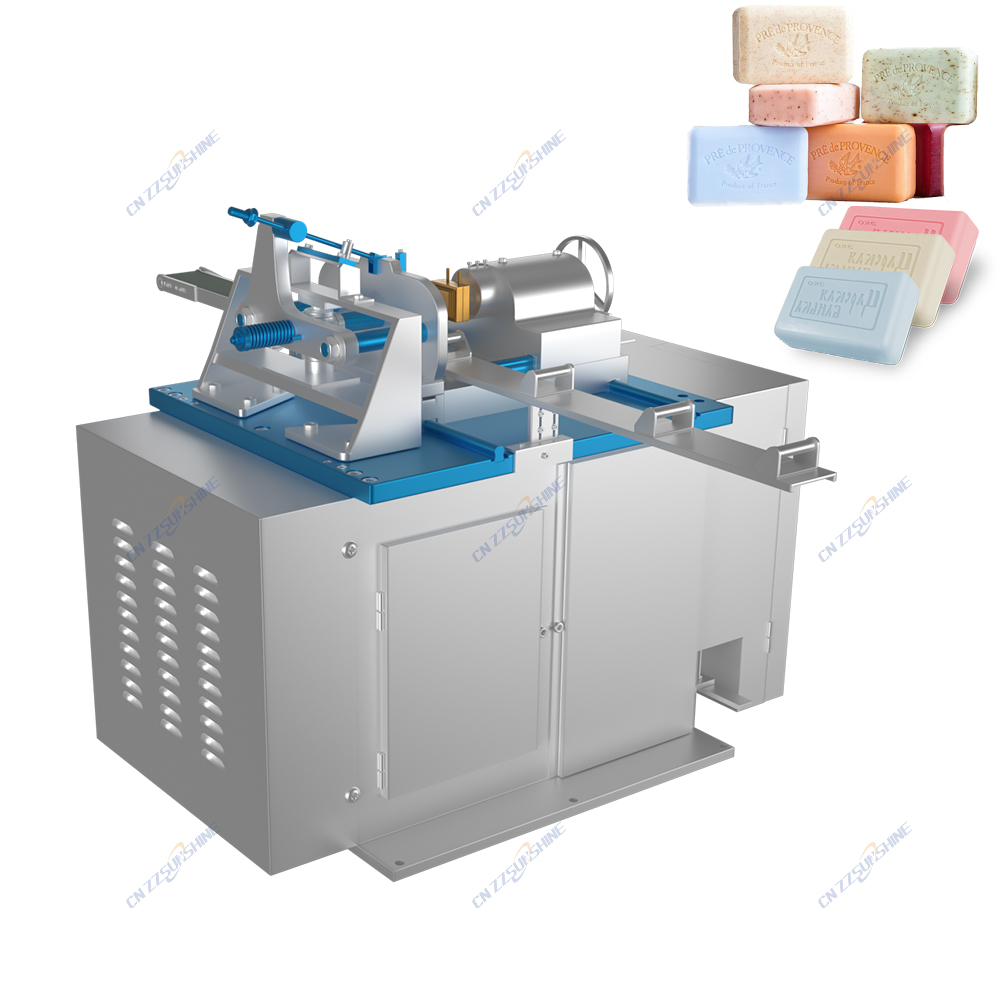

In today’s competitive manufacturing landscape, a robust soap making production line is indispensable for factories aiming to scale operations while maintaining high standards. This integrated system typically includes key components like a vacuum plodder, which eliminates air pockets to produce dense, uniform bars, ensuring consistent texture and longevity. Complementing this is a high-performance soap mixer that facilitates thorough blending of ingredients, preventing separation and enhancing product stability. For precise sizing, an automatic soap cutter delivers clean, accurate cuts with minimal waste, crucial for both laundry bar soap production line and beauty soap making line applications. These elements work seamlessly to boost output, reduce manual labor, and improve overall quality—ideal for everything from toilet soap finishing line setups to bath soap making machine implementations. By investing in such automation, manufacturers can achieve significant cost savings and faster turnaround times. For instance, incorporating an electric washing soap cutter or custom soap cutting machine allows for tailored solutions that meet specific market demands, driving higher profitability. Ultimately, a well-designed automatic soap production line not only streamlines workflows but also supports sustainable practices by minimizing resource consumption and errors.

Innovative Soap Making Production Line for Enhanced Efficiency

Innovative Soap Making Production Line for Enhanced Efficiency

Posted Date:

By:

If you’re interested in our soap manufacturing equipment or would like to learn more about customized solutions tailored to your specific production needs, please fill out the inquiry form below with details such as your required capacity, soap type, level of automation, etc. As a professional manufacturer of soap machinery, we’re ready to provide you with comprehensive information and a competitive quotation—welcome to contact us!