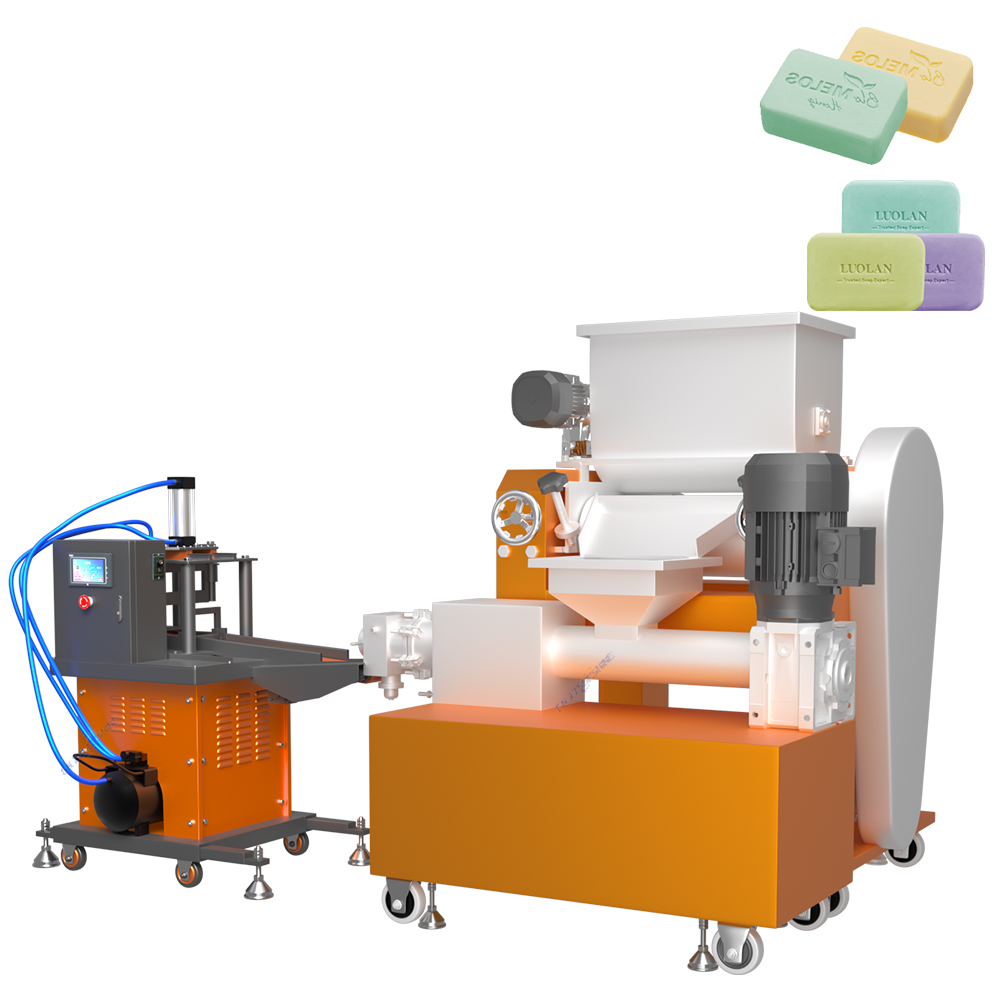

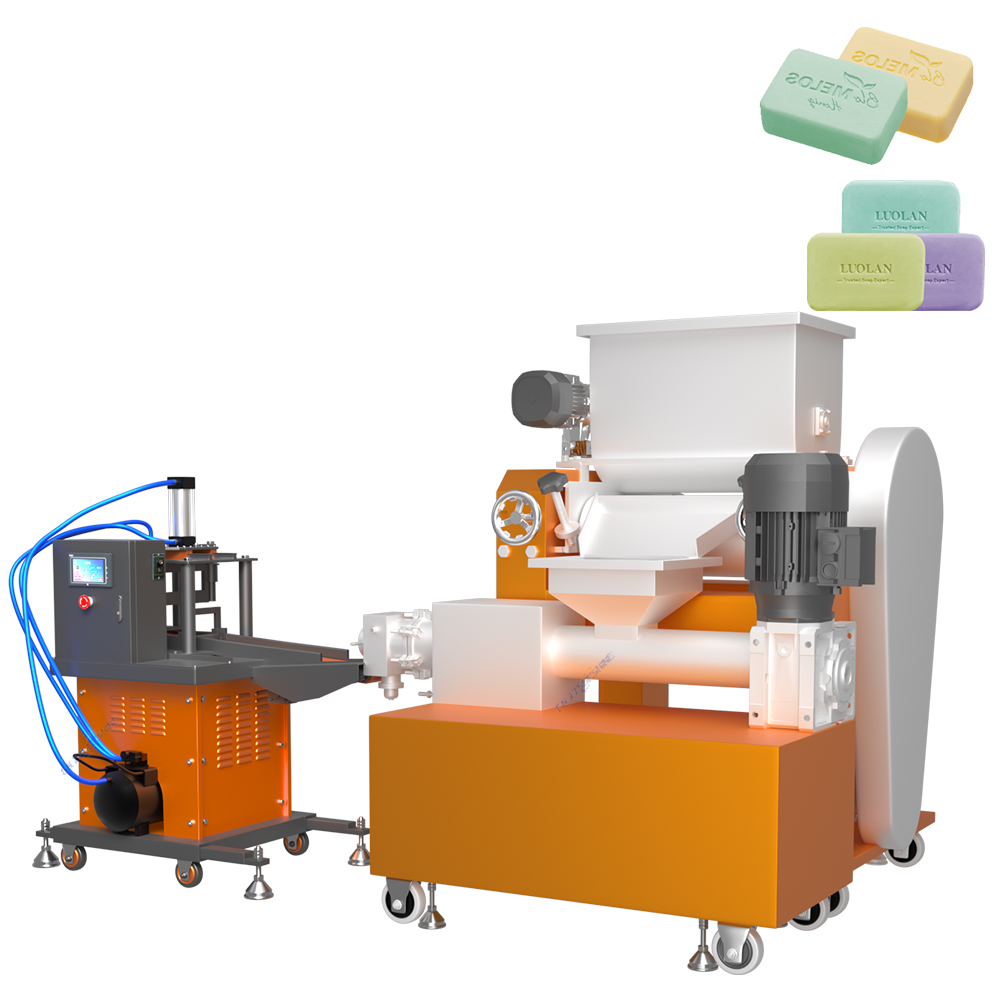

The automatic soap production line has transformed soap manufacturing by integrating advanced machinery for seamless, high-output operations. At its core, the soap plodder machine, especially the vacuum plodder, compresses and refines soap mixtures to eliminate air bubbles, ensuring dense, uniform bars ideal for laundry soap making line or toilet soap finishing line applications. This is paired with an industrial mixer for chemical processing, which homogenizes ingredients like oils and lye efficiently, preventing separation and enhancing bar soap quality. For precise sizing, the electric washing soap cutter offers automated slicing, reducing waste and labor costs, while custom soap cutting machines can be tailored for unique shapes in bath soap making machine setups. To maintain optimal temperatures, an industrial chiller for machinery cools components during continuous runs, preventing overheating and extending equipment life. The line also incorporates a three roller mill for cosmetics-grade soap bases, refining textures for luxury products. Finally, an automatic packing machine for food-grade sealing ensures hygiene and speed in packaging, completing the process. These innovations boost productivity by up to 50%, cut operational expenses, and support diverse outputs like laundry bar soap production line or beauty soap making line variants. By adopting such automated systems, manufacturers achieve scalable, reliable solutions with minimal downtime, making them essential for competitive markets.

Innovations in Automatic Soap Production Line Technology

Innovations in Automatic Soap Production Line Technology

Posted Date:

By:

If you’re interested in our soap manufacturing equipment or would like to learn more about customized solutions tailored to your specific production needs, please fill out the inquiry form below with details such as your required capacity, soap type, level of automation, etc. As a professional manufacturer of soap machinery, we’re ready to provide you with comprehensive information and a competitive quotation—welcome to contact us!