Unlock Efficiency: Your Guide to Modern Solid Soap Production Equipment

The demand for high-quality bar soaps, encompassing laundry, toilet, and specialty beauty bars, continues to thrive. Meeting this demand efficiently requires robust and reliable machinery. Investing in the right soap making production line is paramount for manufacturers aiming to scale operations, ensure consistency, and maintain product integrity. Let’s explore the essential machinery powering today’s successful soap factories.

At the heart of any laundry bar soap production line or toilet soap finishing line lies the soap mixer, also known as a mixing machine. This critical component, often constructed from durable stainless steel, ensures the homogeneous blending of saponified paste, fragrances, colors, and additives. Following thorough mixing, the paste moves to a soap plodder, typically a vacuum plodder which removes air pockets and compresses the mixture into a uniform, dense extrudate ready for forming. The soap plodder machine for bar soap is vital for achieving the desired bar hardness and smooth finish.

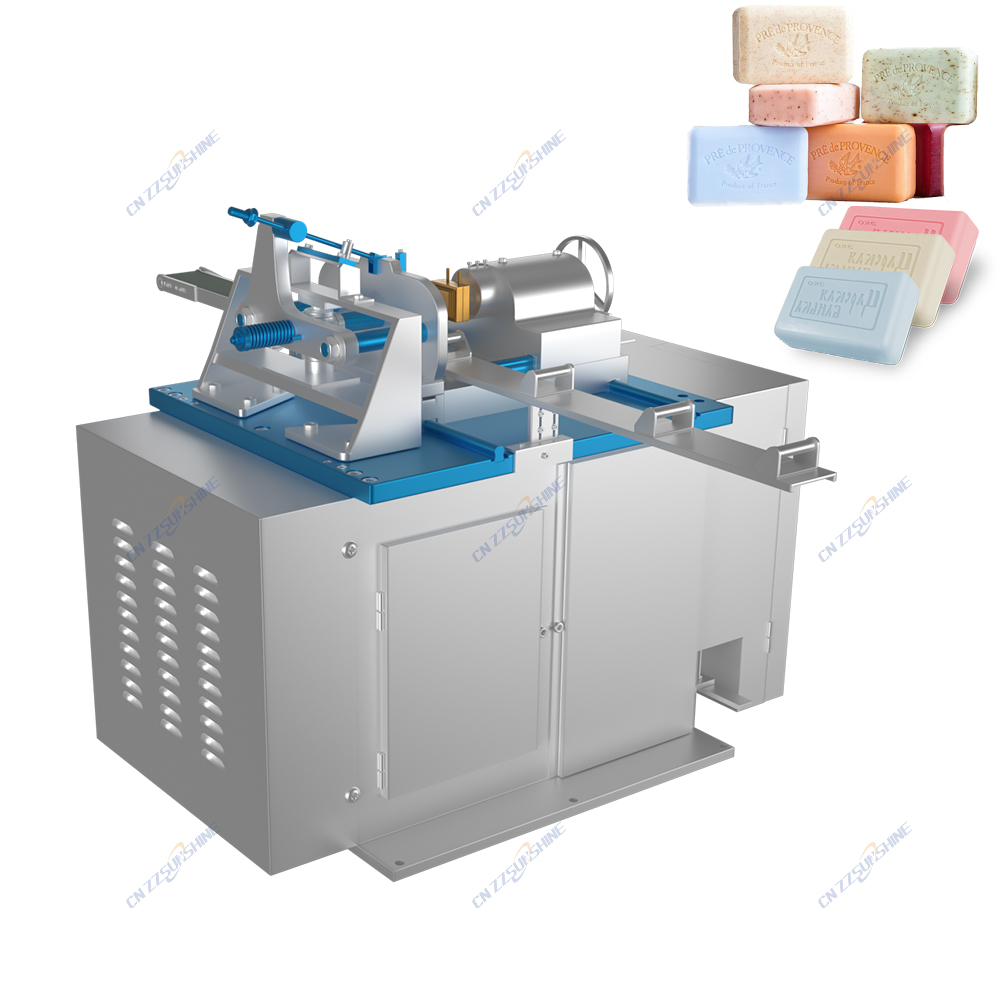

Once extruded, the continuous soap log requires precise sizing. This is where cutting technology comes in. Options range from manual cutting machines for lower volumes to highly efficient automatic block cutter machines. For manufacturers seeking versatility and precision, custom soap cutting machines, pneumatic cutting machines, or electronic cutting machines offer tailored solutions. Electric washing soap cutters are also popular choices for specific applications. The cut soap bars then proceed to shaping and stamping using specialized soap stamping machines, which can be semi-automatic printers or fully automatic printers, imprinting logos and designs.

Finishing the automatic soap production line involves packaging. Film packaging machines efficiently wrap individual bars for retail. For smaller operations or specialized products like beauty soap making lines, a mini soap production line might integrate core components like the mixer, soap plodder, and cutter in a more compact footprint. Additional equipment, such as an OEM three roller grinding mill, might be incorporated for specific refining processes, while washing liquid production equipment caters to diversifying product ranges.

Choosing the right soap making machine combination depends on your specific product type (laundry, toilet, beauty), desired output, and level of automation (from semi-automatic to fully automatic soap production line). Key considerations include the equipment’s construction (stainless steel is preferred), efficiency, ease of cleaning, and the ability to handle your formulations. Partnering with an experienced manufacturer ensures access to reliable custom soap cutting machine solutions, OEM options, and comprehensive support for your soap production line, maximizing your return on investment. Elevate your soap manufacturing capabilities today. Request a quote for your ideal setup!