The Heart of Your Soap Production: Mastering Mixing, Plodding, and Cutting

In the competitive world of soap manufacturing, whether crafting luxurious toilet soaps, robust laundry bars, or specialty beauty soaps, the core of your operation hinges on the efficiency and quality delivered by your core machinery. Selecting the right soap making machine isn’t just about purchasing equipment; it’s about investing in the reliability, consistency, and scalability of your entire soap making production line. At the center of this process lie three critical components: the soap mixer, the soap plodder, and the cutting systems. Let’s delve into why these machines are paramount and how choosing high-quality versions impacts your bottom line.

The Foundation: High Yield Mixing with the Right Soap Mixer

Every exceptional bar of soap begins with a perfectly blended mass. A high-performance mixing machine, specifically designed for soap production, is non-negotiable. This isn’t just about combining ingredients; it’s about achieving a homogeneous blend of oils, fats, alkali, fragrances, colors, and additives under controlled conditions. Whether integrated into a comprehensive laundry soap making line or a specialized beauty soap making line, the mixer sets the stage for quality.

Why Quality Matters: Inferior mixing leads to inconsistencies – streaks, uneven saponification, or poorly distributed additives. This directly impacts the final bar’s appearance, fragrance throw, lathering properties, and skin feel. A high yield mixing machine ensures maximum output with minimal waste, processing large batches efficiently and uniformly. Look for robust construction, efficient motor systems, and designs that prevent dead zones where material can accumulate unmixed.

The Solid Particle Challenge: For processes involving dry additives like exfoliants or clays, a solid particle mixing mixer capability is essential. It must thoroughly incorporate these particles without breaking them down excessively or creating air pockets that lead to voids in the final extruded soap log.

Refining the Texture: The Critical Role of the Soap Plodder

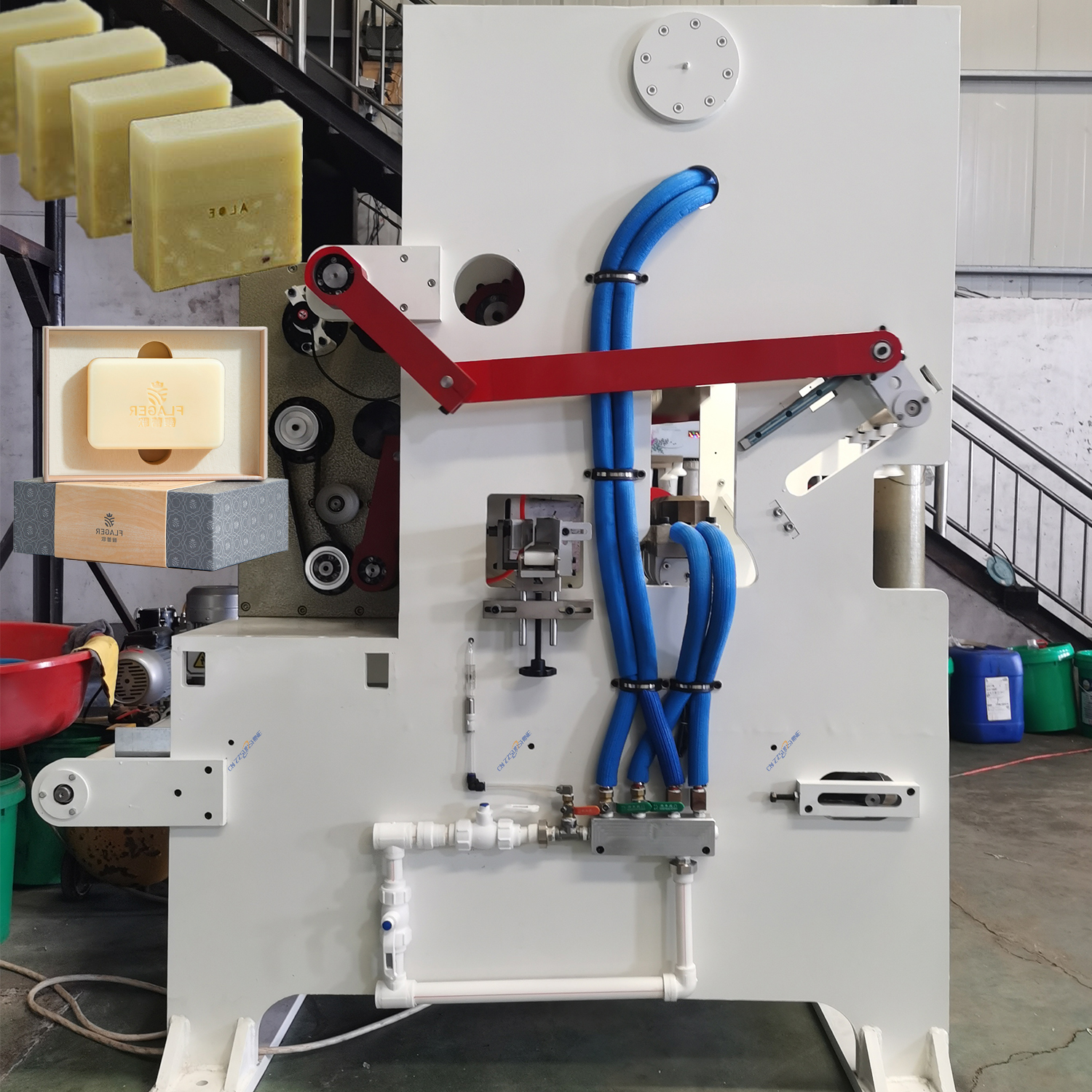

Once mixed, the soap base undergoes refining and compaction in the soap plodder machine for bar soap. This machine is the workhorse responsible for creating the dense, smooth, and uniform texture characteristic of a quality bar. Plodders work by forcing the soap mass through a series of screens or under vacuum conditions.

Vacuum Plodder Advantage: A vacuum plodder is often the gold standard, especially for high-quality toilet and beauty soaps. Operating under vacuum removes trapped air bubbles from the mixed mass. This is crucial because air bubbles lead to pitting, cracking, or a rough finish in the final stamped bar. The result is a significantly denser, smoother, and more visually appealing soap log ready for cutting.

Plodding Efficiency: The efficiency of your plodder directly affects throughput. A high-quality plodder ensures consistent extrusion pressure and log formation, minimizing downtime and maximizing the output of your automatic soap production line.

Precision Cutting: From Log to Bar

The final step before stamping and packaging is cutting the continuous extruded soap log into individual bar-sized pieces. Precision here is vital for weight accuracy, appearance, and minimizing waste. Cutting systems range from manual cutting machine options for smaller or artisanal setups to highly sophisticated automatic block cutter machine units integrated into full automatic soap production lines.

Accuracy is Key: Whether it’s a pneumatic cutting machine, electronic cutting machine, or specifically an electric washing soap cutter, the system must deliver clean, consistent cuts with minimal residue (“soap fines”). Weight control is critical for meeting regulatory standards and customer expectations. A custom soap cutting machine might be necessary for unique bar shapes or sizes beyond standard offerings.

Integration: In a fully automated line, the cutter works seamlessly with the plodder and downstream equipment like the soap stamping machine and film packaging machine, ensuring a smooth, continuous flow with minimal manual handling.

Building Your Optimal Line: Customization and Support

No two soap factories are identical. Your production volume, target market (toilet soap, laundry bar, beauty soap), and specific product characteristics (ingredients, shape, size) dictate the ideal configuration. This is where partnering with a knowledgeable equipment manufacturer becomes invaluable.

Tailored Solutions: Look for suppliers offering custom soap cutting machine options or the ability to integrate specific components like an OEM three roller grinding mill if your process requires additional refining before plodding. Whether you need a compact mini soap production line or a sprawling laundry bar soap production line, flexibility in design is key.

Comprehensive Support: From the initial soap mixer selection to the final soap stamping machine integration, expert guidance ensures each component works harmoniously. Consider the availability of parts, technical support, and training for your operators.

Conclusion: Investing in Core Performance

While auxiliary equipment like washing liquid production equipment, semi-automatic printers, or automatic printers play their roles, the triumvirate of the high yield mixing machine, the soap plodder, and the precision cutter forms the undeniable heart of your soap making machine operations. Investing in high-quality, reliable, and appropriately specified core machinery – be it a robust soap mixer, an efficient vacuum plodder, or an accurate automatic block cutter machine – translates directly into superior product quality, increased production yields, reduced waste, and ultimately, a stronger competitive position in the demanding soap market. Choose your core equipment wisely; it’s the foundation upon which your soap-making success is built.