Your Compact Powerhouse: High Quality Mini Soap Finishing Line Equipment for Small Bar Soap Making Success

The dream of crafting beautiful, high-quality bar soap – whether luxurious toilet soaps, reliable laundry bars, or niche beauty products – is a compelling one. But for small-scale producers, startups, or businesses looking to expand their offerings without massive capital investment, the scale and cost of full industrial soap making production lines can seem daunting. That’s where the right mini soap production line becomes not just an option, but a strategic game-changer. Specifically designed for efficiency and affordability, a well-chosen small bar soap making machine setup empowers you to produce professional-grade products consistently.

Why a Mini Soap Finishing Line Makes Perfect Sense

Investing in a compact soap finishing line offers distinct advantages:

1. Lower Capital Investment: Significantly more affordable upfront than large-scale industrial automatic soap production line systems.

2. Reduced Footprint: Perfect for smaller workshops, boutique operations, or businesses where space is at a premium.

3. Flexibility & Scalability: Ideal for producing smaller batches, testing new formulas (like specialized beauty soap making line products), or gradually scaling up production as demand grows.

4. Targeted Production: Focuses resources on the essential finishing stages – refining, extruding, cutting, and stamping – ensuring a polished final product ready for market. This is especially crucial for both toilet soap finishing line and laundry bar soap production line outputs.

5. Easier Operation & Maintenance: Often designed with user-friendliness in mind, requiring less specialized training than complex, fully automated systems.

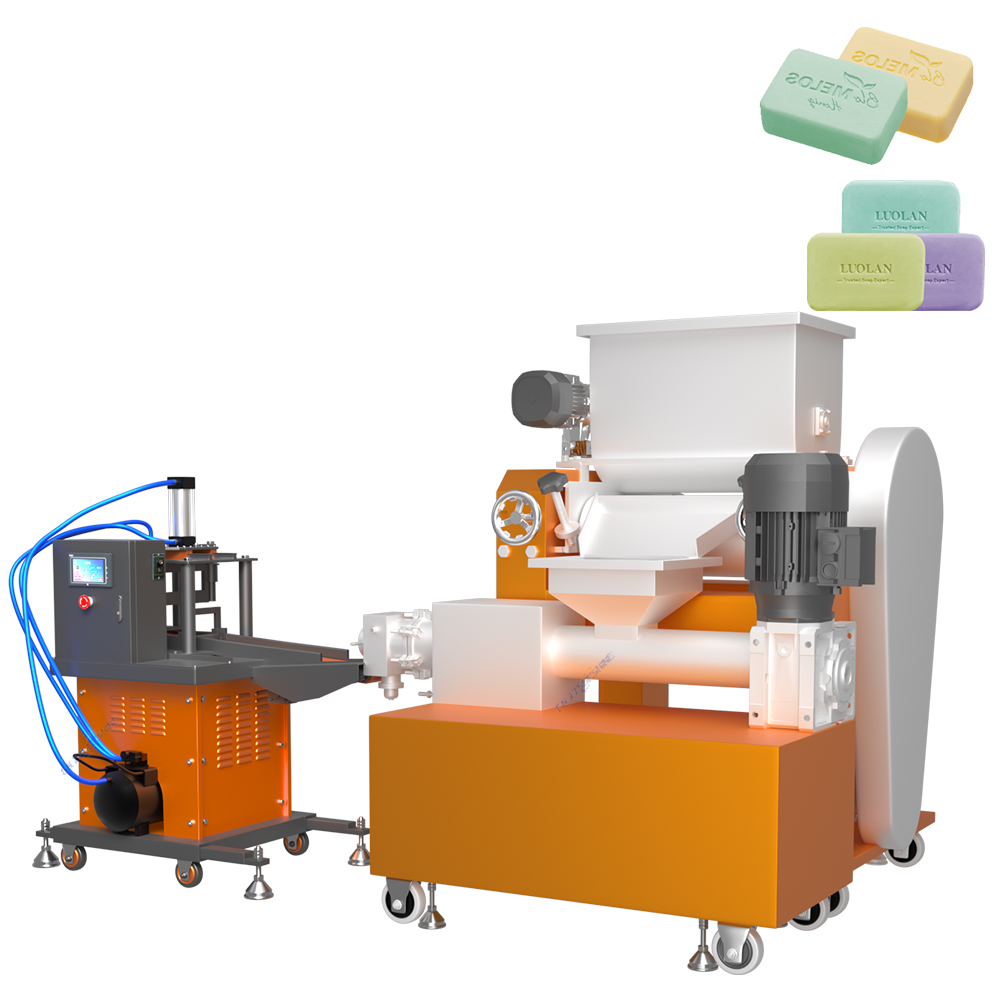

Core Components of a High-Performing Mini Soap Line

A truly effective mini soap production line isn’t just about being small; it’s about smart integration of key machinery designed to work together seamlessly. Let’s break down the typical components you’ll find in a quality setup:

1. The Mixing Machine Foundation: Before anything else, consistent soap base quality starts here. While your line might start with pre-made noodles, a robust soap mixer or mixing machine is crucial if you’re compounding from scratch or refining base stock. This ensures uniform incorporation of fragrances, colors, and additives – the bedrock of quality.

2. Refining & Homogenizing: This is where texture and quality are significantly enhanced. An OEM three roller grinding mill is often the workhorse here, meticulously refining the soap mass, removing air pockets, and creating a smooth, dense consistency essential for premium bars. This step is vital for both laundry soap making line durability and toilet soap finishing line luxury feel.

3. The Heart of Extrusion: The Soap Plodder: This is arguably the most critical piece for bar quality. A vacuum plodder is the gold standard, even in mini lines. Why? It continuously extrudes the soap under vacuum pressure, eliminating air bubbles that cause crumbling and ensuring a solid, long-lasting bar. Look for reliable soap plodder machine for bar soap options designed for smaller throughput but uncompromised on vacuum performance. The soap plodder delivers the continuous log ready for cutting.

4. Precision Cutting: The Soap Cutting Cutter: Transforming the extruded log into individual bars requires accuracy and consistency. This is where your soap cutting cutter comes in. Options range from manual cutting machines (simple but labor-intensive) to electronic cutting machine or pneumatic cutting machine models offering greater speed and precision. An automatic block cutter machine integrated into the line can significantly boost output and uniformity. Choosing the right custom soap cutting machine depends heavily on your desired volume and automation level. Electric washing soap cutter variants are also popular for their efficiency.

5. Branding & Finishing Touches: Giving your bars a professional identity is key. A soap stamping machine, potentially a semi-automatic printer or automatic printer, imprints your logo or design onto each bar. For wrapping, a compact film packaging machine efficiently seals and protects the finished product.

Finding Value: Small Bar Soap Making Machine at Savon Factory Price

The term “savon factory price” signifies the goal: acquiring industrial-grade reliability and performance at a price point accessible to smaller manufacturers. Reputable suppliers understand the needs of this market segment. They offer these high quality mini soap finishing line equipment packages, often allowing for some customization (like specific cutter types or plodder configurations) to best suit your product type (beauty soap vs. laundry bar) and budget.

Maximizing Your Mini Line Investment

To get the most from your small bar soap making machine setup:

Define Your Needs: Clearly outline your target products (toilet, laundry, beauty), batch sizes, and desired output.

Prioritize Quality: Don’t compromise on core components like the vacuum plodder or refining mill. These directly impact bar quality and longevity.

Consider Future-Proofing: If growth is part of the plan, discuss modular options or machines that can handle slightly higher capacities.

Supplier Support: Choose a supplier offering reliable installation guidance, training, and accessible spare parts. Good support is invaluable.

Focus on Process: Even with great equipment, consistent results rely on mastering the soap making process itself – temperatures, formulations, curing times.

Conclusion: Empowerment Through Smart Machinery

A high quality mini soap finishing line equipment package is far more than just a collection of machines; it’s a strategic investment in your small-scale soap making future. By incorporating essential elements like a robust soap plodder machine for bar soap, a precise soap cutting cutter, and efficient refining and finishing tools, you gain the capability to produce professional, market-ready bars efficiently and cost-effectively. Explore options designed to deliver true savon factory price value, empowering you to turn your soap making vision into a thriving, scalable reality with your dedicated mini soap production line.