Optimizing Your Soap Manufacturing: Essential Equipment for Quality & Efficiency

For businesses aiming to deliver premium laundry bars, elegant toilet soaps, or specialized beauty soaps, investing in the right soap making production line is paramount. This equipment directly impacts product quality, consistency, and operational efficiency, giving you a competitive edge.

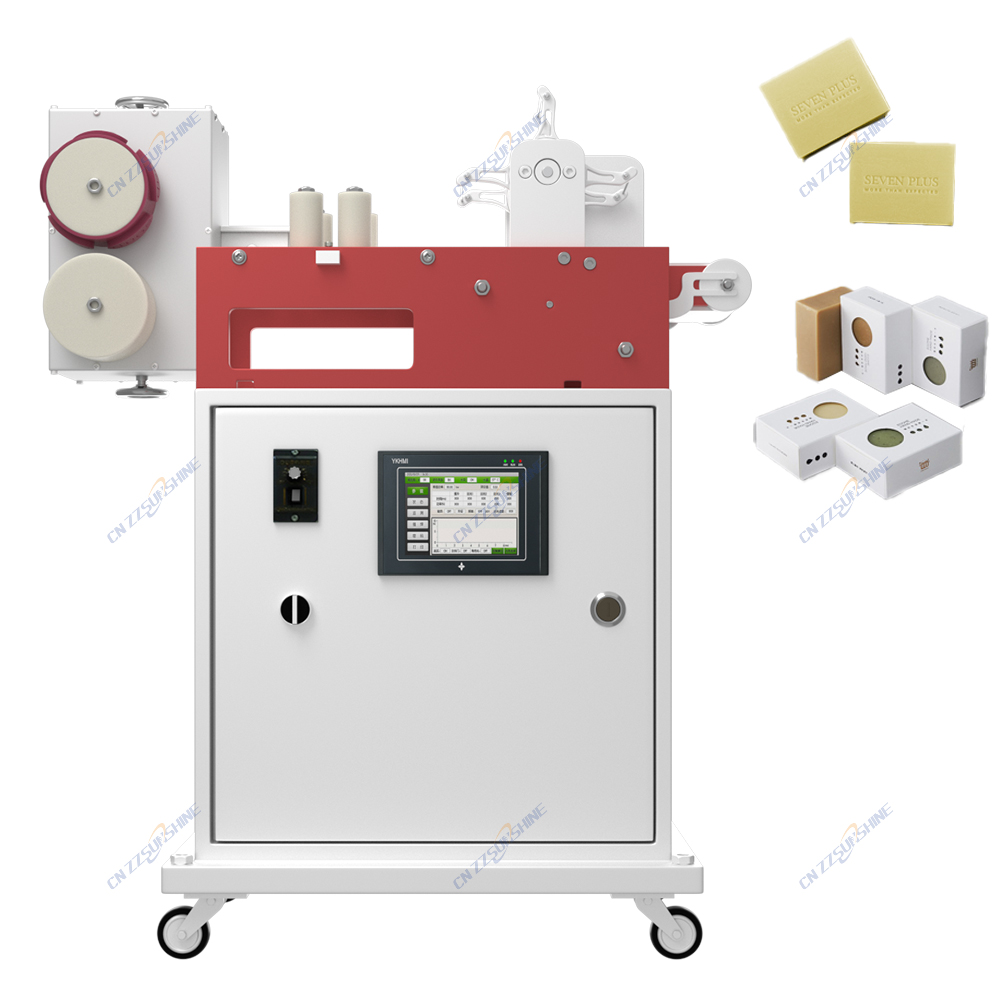

A robust laundry soap making line or toilet soap finishing line integrates several key components. It begins with efficient mixing machines and soap mixers to blend raw materials uniformly. For bar soap, a soap plodder machine, especially a vacuum plodder, is crucial for high-pressure extrusion, removing air pockets, and forming a dense, homogenous soap noodle. This ensures the final bar’s durability and lather. Following extrusion, precise cutting is achieved using an automatic block cutter machine or custom soap cutting machine, available as electronic cutting machines, pneumatic cutting machines, or manual cutting machines, depending on automation needs. Further refinement might involve an OEM three roller grinding mill for specific textures. Finally, soap stamping machines and film packaging machines add branding and protection.

Whether you require a comprehensive automatic soap production line or a modular mini soap production line, selecting reliable soap making machinery – including high-performance soap plodders, cutters, and finishing units – is essential. Partner with experienced manufacturers to source equipment that meets your specific production volume and quality goals for laundry bar soap production or premium beauty soap making.