Unlock Efficiency: The Power of Modern Soap Manufacturing Equipment

The soap industry, whether focused on laundry bars, luxurious toilet soaps, or beauty products, thrives on consistency, quality, and volume. Achieving these goals manually is not only laborious but also limits growth potential. This is where investing in a high-productivity soap making machine becomes essential. Modern automatic soap production line solutions transform raw materials into finished bars efficiently and reliably.

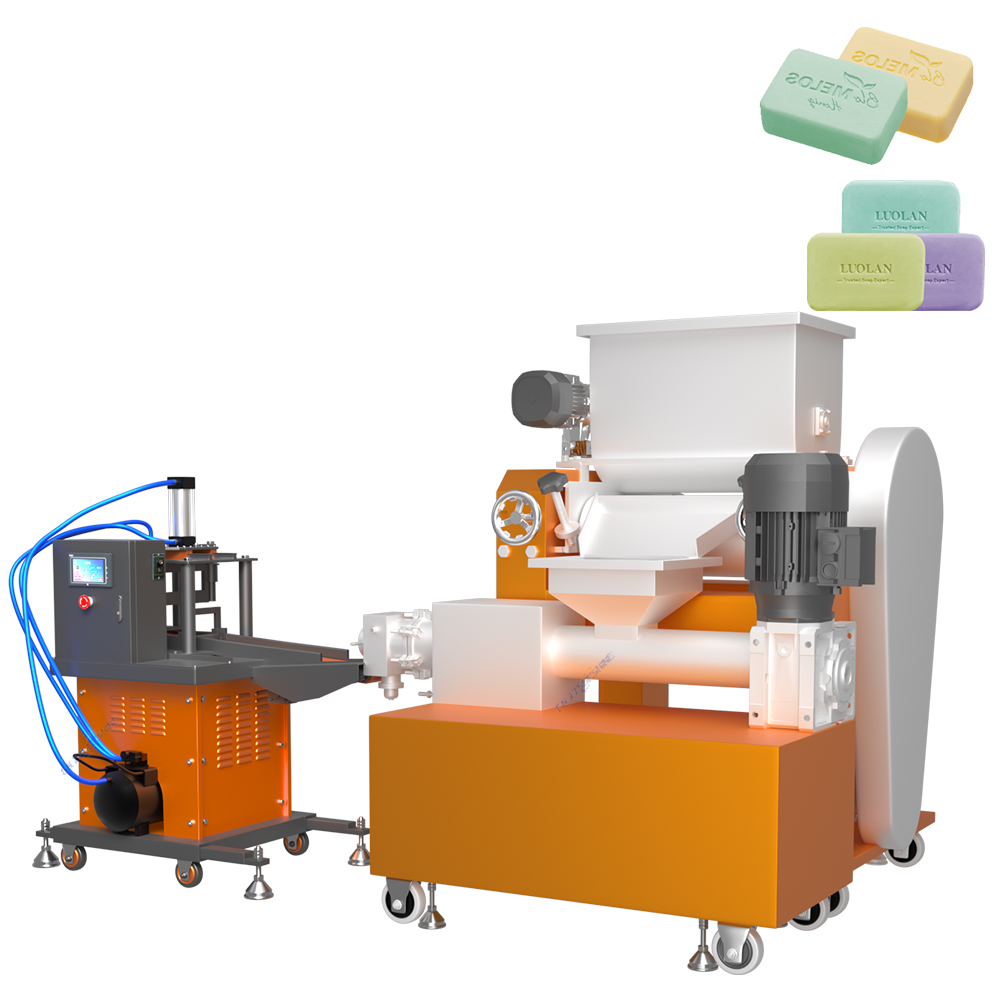

At the core of any robust soap making production line lies the processing equipment. A high-quality soap mixer or mixing machine ensures the saponified soap base, fragrances, colours, and additives are blended uniformly. For achieving the desired texture and removing air pockets, a vacuum plodder is indispensable. This soap plodder machine for bar soap kneads and compresses the soap mass under vacuum, resulting in a dense, smooth, homogenous noodle ready for forming. Further refining can be achieved using an OEM three roller grinding mill for ultra-fine consistency, particularly important for premium toilet soaps.

The formed soap noodles then move to the shaping stage. Automatic soap molding machinery takes centre stage here, precisely extruding the soap mass into continuous logs of the required shape and density. This is where the transition from raw material to recognizable bar happens efficiently. Following extrusion, precise cutting is critical. Automatic block cutter machine options abound, including electric washing soap cutter, pneumatic cutting machine, and electronic cutting machine variants. These custom soap cutting machine units slice the extruded logs into individual bars with minimal waste and consistent weight, far surpassing the capabilities of any manual cutting machine.

Finishing the bars requires branding and protection. A soap stamping machine imprints logos or designs onto the soap surface. Finally, packaging safeguards the product and enhances its shelf appeal. Film packaging machine units efficiently wrap individual bars or multipacks, completing the laundry soap making line or toilet soap finishing line. For liquid products, dedicated washing liquid production equipment would be integrated separately.

Whether you operate a large-scale laundry bar soap production line, a specialized bath soap making machine setup, or even a compact mini soap production line, automating key processes is the key to scaling up. Integrating components like a semi-automatic printer or automatic printer for labelling further streamlines operations. By embracing automatic soap production line technology, manufacturers significantly boost output, ensure product uniformity, reduce labour costs, and enhance overall operational efficiency. Explore the possibilities modern machinery offers and elevate your soap production today.