The Smart Choice: High Efficiency Small Bar Soap Production Lines

For entrepreneurs and small to medium-sized businesses entering the soap market, finding the right equipment can be daunting. You need machines that are efficient, space-conscious, and versatile enough to handle diverse product lines – from luxurious bath soaps to robust laundry bars. This is where a High Efficiency Small Bar Soap Production Line shines. Combining compact design with robust capabilities, these lines offer a powerful solution without the footprint of large industrial setups.

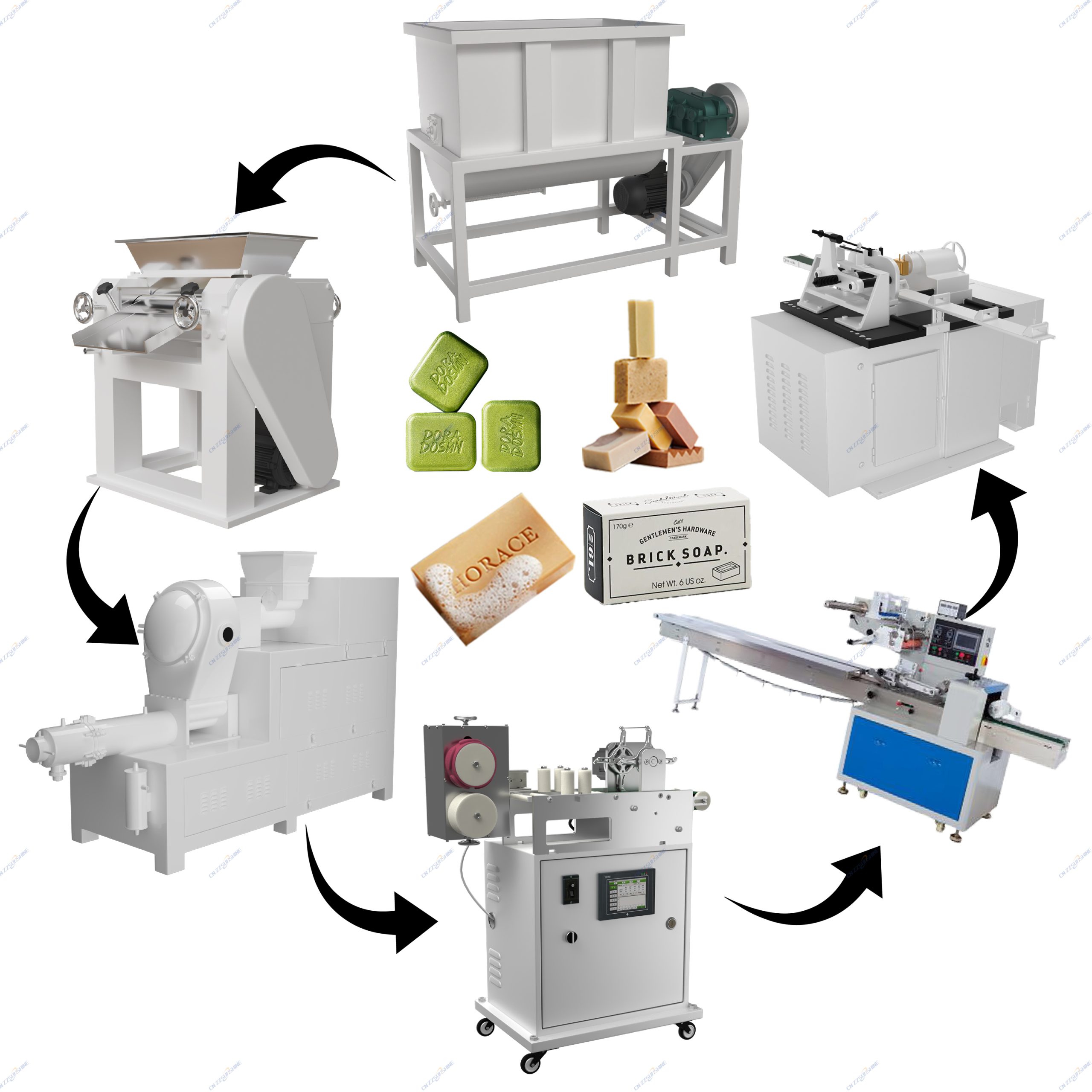

At the heart of such a line lies the soap plodder machine for bar soap, specifically the Vacuum plodder. This critical component refines the soap base, removing air pockets and moisture under vacuum conditions. The result? A denser, smoother, and longer-lasting bar soap with superior lather and quality. Paired with a reliable soap mixer or Mixing machine, you ensure consistent blending of ingredients, whether creating simple laundry soap bases or complex beauty soap formulations for a dedicated beauty soap making line.

Processing the mixed soap mass efficiently is key. An automatic block cutter machine or custom soap cutting machine streamlines this step. Options range from Manual Cutting Machines for ultimate flexibility to Electronic Cutting Machines or Pneumatic Cutting Machines for higher throughput and precision. Following cutting, the Soap Stamping Machine becomes essential. This is where branding magic happens – whether using a Semi-automatic Printer or a fully Automatic Printer to press your unique LOGO onto each bar, instantly elevating your product’s professionalism and market appeal.

For businesses focusing on laundry soap, a dedicated laundry soap making line or laundry bar soap production line within this compact framework ensures efficient production of high-demand products. Conversely, a toilet soap finishing line or bath soap making machine setup caters to the premium end of the market, emphasizing refinement and aesthetics.

Completing the line, a Film Packaging Machine provides neat, protective wrapping, readying bars for sale. The beauty of these small-scale soap making production lines is their adaptability. They can integrate OEM three roller grinding mill units for specific refining needs or connect seamlessly to Washing Liquid Production Equipment for diversified offerings.

In essence, investing in a High Efficiency Small Bar Soap Production Line / Soap Mould Machine and Equipment Press LOGO Manual Soap setup is an investment in flexibility, quality, and branding power. It allows smaller producers to compete effectively by delivering professional-grade products with efficient, scalable machinery. Whether starting out or looking to optimize existing production, this focused approach to soap making machine technology offers a compelling path to success.