Crafting Excellence: The Heart of Soap Production Machinery

In today’s demanding market, producing high-quality soap – whether laundry bars, beauty soaps, or toilet soaps – requires more than just good ingredients; it demands precision machinery. The backbone of any successful soap making production line lies in its core equipment: efficient mixers, reliable plodders, and accurate cutting and stamping units.

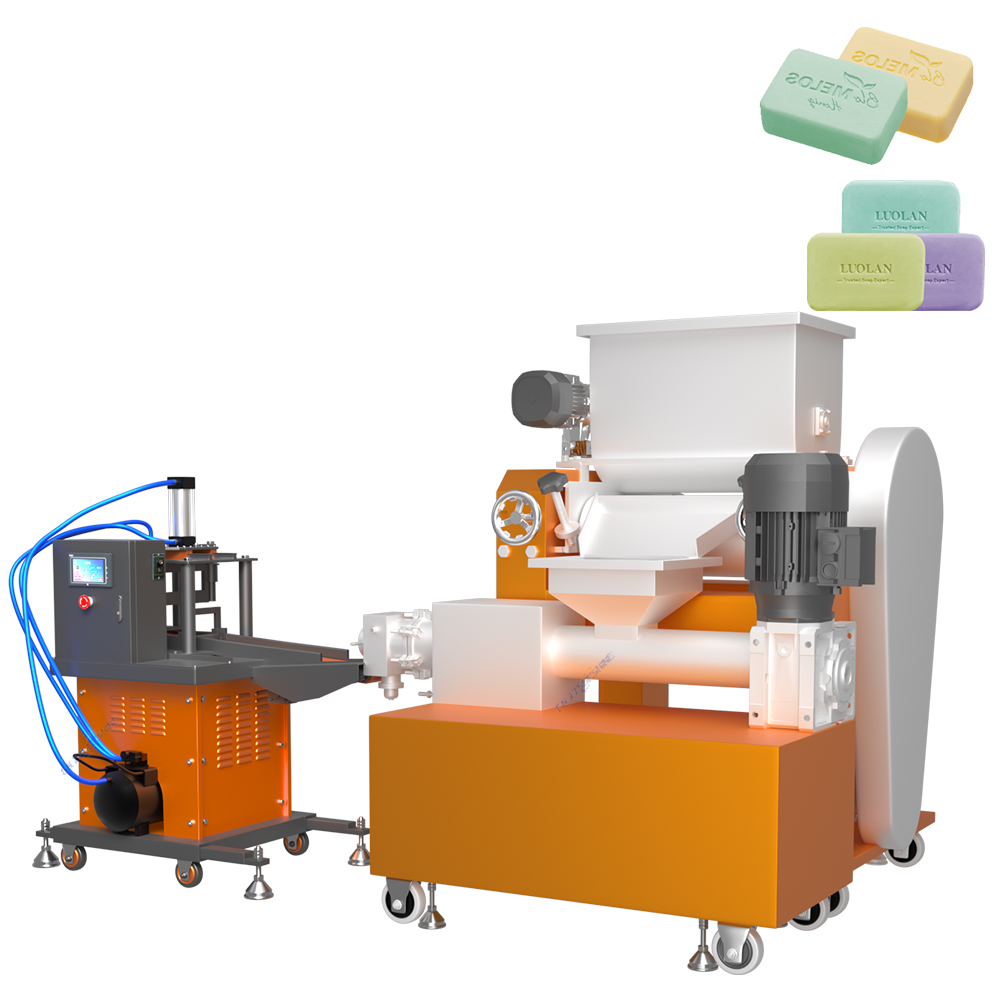

Consider the crucial blending stage. A robust soap mixer ensures homogeneous mixing of fats, oils, and additives, creating the perfect soap noodle base. This mixture is then fed into a soap plodder machine for bar soap, often a vacuum plodder, which compresses, homogenizes, and extrudes the soap mass into a continuous bar. For premium laundry soap, a specialized laundry soap making line incorporates a soap noodle grinding machine to refine texture, while a green soap making machine washing clothes might emphasize specific environmental features.

Downstream, the extruded soap log meets cutting precision. Options range from manual cutting machines to sophisticated automatic block cutter machines or pneumatic cutting machines. Each cut bar then moves to stamping, where an automatic printer or soap stamping machine imprints branding with consistency. Finally, a film packaging machine ensures the finished product is protected and shelf-ready.

Whether you need a compact mini soap production line, a semi-automatic printer, or a fully integrated automatic soap production line, selecting the right combination – like a high-performance OEM three roller grinding mill or a custom soap cutting machine – is paramount. From bath soap making machines to washing liquid production equipment, investing in quality machinery tailored to your specific needs is the key to efficient, high-output, and superior soap manufacturing. What will your next production upgrade be?