Unlock Efficiency & Customization: The Future of Soap Production

The demand for unique, tailored soap products is surging. Whether it’s bespoke laundry bars for eco-conscious consumers, specialized formulations for hotels seeking brand identity, or innovative beauty soaps, the ability to customize is key. Meeting this demand requires smart, efficient production solutions. Enter the modern soap making machine – the cornerstone of adaptable, high-quality manufacturing.

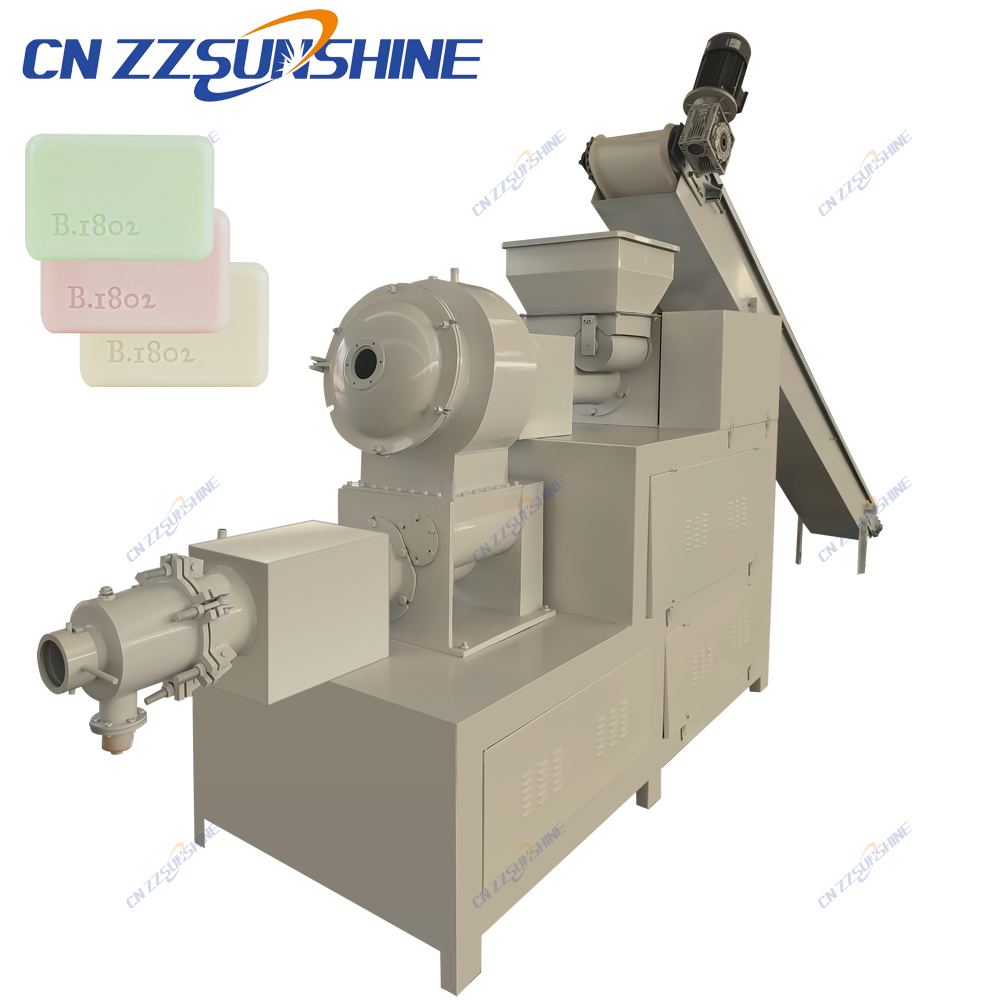

For businesses focusing on laundry soap making lines, efficiency and consistency are paramount. A green customized laundry soap making machine empowers producers to create specific formulations with minimal waste. These systems often integrate seamlessly with automatic block cutter machines and soap plodder machines for bar soap, ensuring a smooth transition from raw materials to finished bars. The heart of many setups, the soap plodder, particularly models like the Vacuum plodder, plays a critical role in refining texture and density, crucial for both laundry and toilet soap quality. Pairing this with a robust soap mixer or automatic soap noodles mixing machine guarantees uniform blending of ingredients, laying the foundation for superior product consistency.

Customization extends beyond just the formula. Shape, size, and branding are vital differentiators. A custom soap cutting machine, such as an Electric washing soap cutter, Pneumatic Cutting Machine, or Electronic Cutting Machine, provides precise control over bar dimensions. For intricate designs or specific hotel branding, an Automatic Soap Stamping Machine adds that final, professional touch. Integrating a Film Packaging Machine completes the automatic soap production line, offering streamlined, attractive wrapping. This level of automation, achievable even with a Mini Soap Production Line or Semi-automatic Printer, allows smaller producers to compete effectively.

The toilet soap finishing line demands similar precision and flexibility. Achieving the desired smoothness and sheen often involves equipment like the OEM three roller grinding mill, essential for refining paste before extrusion in the soap plodder machine. Whether producing bath soap or beauty bars, the integration of Mixing machines, efficient cutters, and reliable plodders ensures a premium finish. For businesses scaling up, a comprehensive Automatic Soap Production Line or laundry bar soap production line incorporates all these elements – from mixing and refining in the soap plodder to cutting, stamping, and packaging – maximizing throughput while maintaining quality.

For ventures focused on liquid products, Washing Liquid Production Equipment offers parallel capabilities for diversification. The choice between a Manual Cutting Machine for smaller batches or a fully Automatic Printer for high-volume output depends on scale, but the goal remains the same: efficient, adaptable production.

Investing in the right soap making production line technology is an investment in your brand’s future. Whether you require a sophisticated Automatic soap production line for large-scale laundry bar manufacturing or a bath soap making machine setup for boutique beauty soaps, modern equipment delivers the precision, flexibility, and efficiency needed to thrive in a competitive market. Embrace customization, enhance quality, and streamline operations with the advanced machinery powering today’s innovative soap producers.