Good Quality Small Integrated Soap Manufacturing Production Plant Make Machine Line for Soap Production

For entrepreneurs and small-scale manufacturers venturing into the soap industry, finding efficient and reliable production equipment is paramount. The dream of producing high-quality bar soaps – whether luxurious bath bars, functional laundry soaps, or specialized beauty soaps – can become a reality with the right soap making production line. Investing in a well-designed, compact, and integrated system offers a significant competitive edge, balancing cost-effectiveness with consistent output.

A typical, good quality mini soap production line or semi-automatic soap production line integrates several key machines, each playing a vital role in transforming raw materials into finished, market-ready bars. The journey begins with the soap mixer or mixing machine, where fats, oils, alkali, and additives are combined into a homogenous paste. For formulations requiring ultra-fine texture and smoothness, such as high-end toilet soaps or exfoliating bars, an OEM three roller grinding mill is essential. This equipment refines the soap mixture to a silky consistency through precise micron-level grinding.

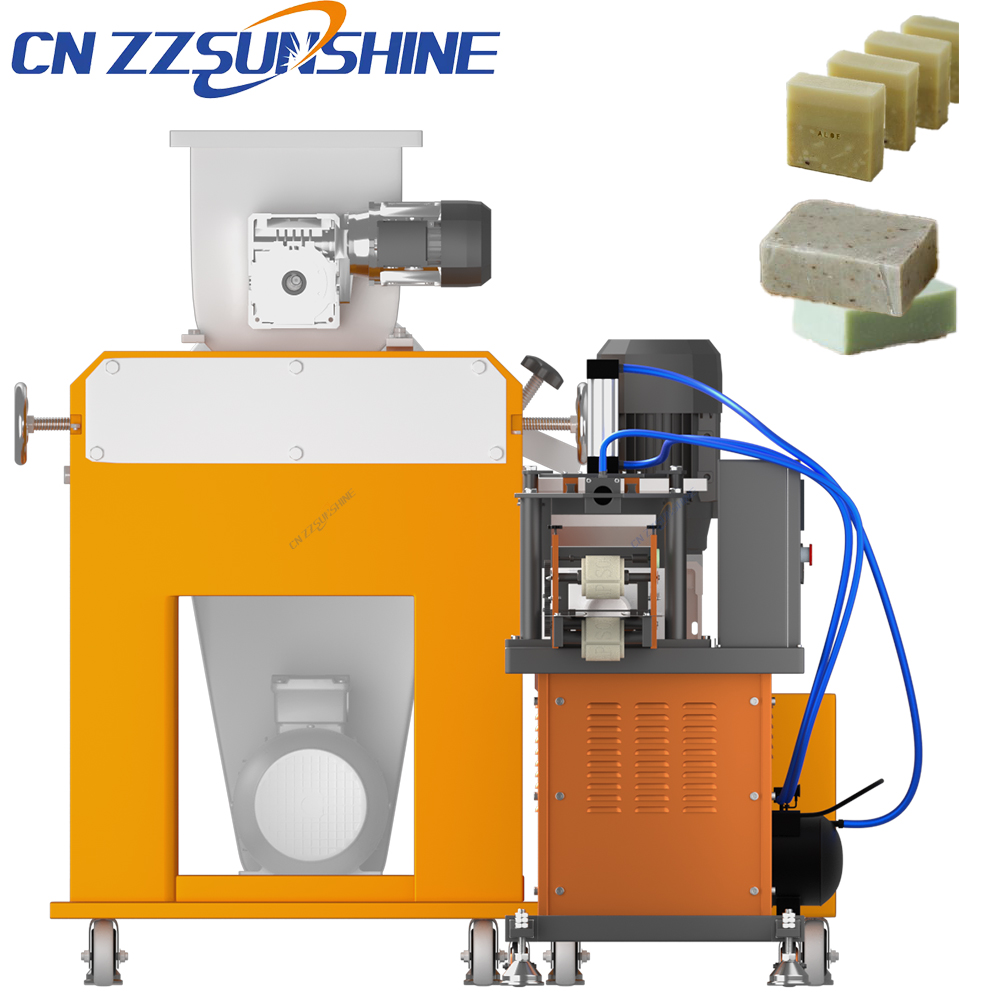

The heart of shaping the soap lies in the soap plodder machine for bar soap, often a vacuum plodder. This critical component compresses the mixed soap, removing air pockets (ensuring density and longer-lasting bars) and extruding a continuous, solid log of soap. The vacuum function is particularly crucial for producing premium, bubble-free toilet soap finishing line products. Following extrusion, the soap log moves to cutting. Here, options range from manual cutting machines for very low volume or artisanal setups to highly efficient automatic block cutter machines. For enhanced precision and hygiene, pneumatic cutting machines or electronic cutting machines offer excellent control and speed, producing uniformly sized soap blanks.

Finally, branding and packaging add the finishing touches. An automatic printer or semi-automatic printer imprints logos or designs onto each soap bar. The line often culminates with a film packaging machine, wrapping the soaps individually or in sets for protection and presentation. Whether setting up a laundry bar soap production line, a beauty soap making line, or a versatile bath soap operation, the integration of these components – soap plodder, cutter, printer, packager – creates a seamless workflow.

Choosing a custom soap cutting machine or seeking OEM options allows tailoring the line to specific bar sizes, shapes, and production volumes. A good quality small integrated soap manufacturing production plant make machine line provides the foundation for efficient, scalable, and profitable soap production, enabling smaller players to deliver professional-grade products consistently to their customers.