Unlock Small-Scale Success: Your Guide to Efficient Soap Production

Starting or scaling a soap business? For crafters, startups, and small manufacturers, finding efficient equipment that doesn’t compromise on quality is key. The quest for compact, reliable machinery often leads to one standout solution: the Fully Automatic Small Soap All-In-One Machine. This innovative equipment is rapidly becoming the Hot Selling Small Soap Equipment for good reason – it streamlines production without demanding a massive footprint or budget.

Why Choose a Small Soap Making Production Line?

Traditional large-scale soap making machines are powerful but often impractical for smaller operations. They require significant space, investment, and manpower. Enter the modern Mini Soap Production Line, designed specifically for lower volumes but higher flexibility. These systems allow businesses to produce professional-grade bar soaps – whether laundry bar soap, luxurious bath soap, or intricate beauty soap – with remarkable efficiency.

The Heart of Compact Production: The All-In-One Advantage

The Fully Automatic Small Soap All-In-One Machine typically integrates core functions. Think of it as a compact Automatic soap production line in one unit. Here’s what makes it so effective:

1. Integrated Mixing: A robust soap mixer or Mixing machine ensures consistent blending of oils, lye, fragrances, and additives. This foundational step is critical for soap quality.

2. Refining & Homogenizing: Many units incorporate refining stages similar to an OEM three roller grinding mill, creating a smooth, uniform soap paste. This step is vital for premium bar soaps.

3. Vacuum Plodding: A compact Vacuum plodder component removes air bubbles, resulting in a denser, longer-lasting bar. This feature is crucial for both toilet soap finishing line quality and laundry soap making line durability.

4. Precise Cutting: Instead of a bulky custom soap cutting machine or separate Manual Cutting Machine, these all-in-one units often feature integrated cutting mechanisms. Options might include Electric washing soap cutter, Electronic Cutting Machine, or Pneumatic Cutting Machine technology for clean, consistent bar sizes.

Beyond the All-In-One: Complementary Equipment for a Complete Line

While the all-in-one unit handles the core process, a truly efficient small soap making production line often benefits from a few additional pieces:

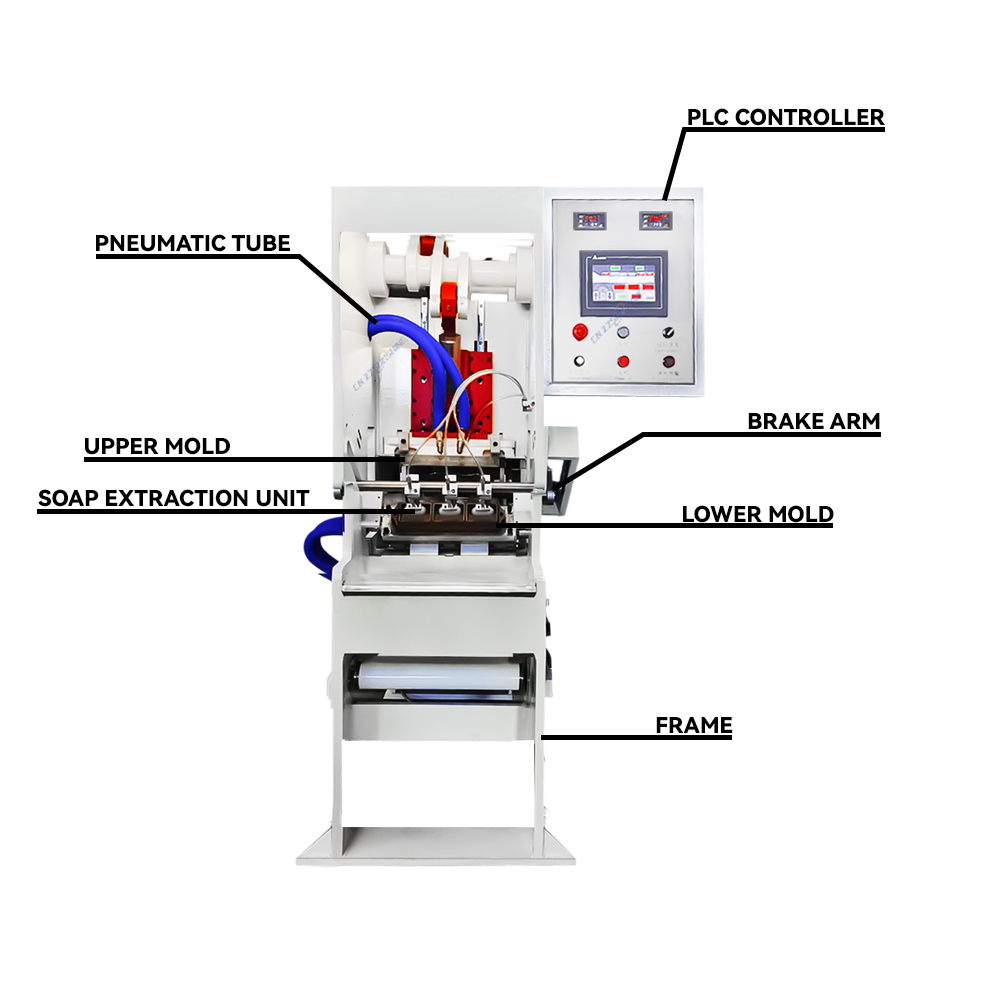

Stamping for Brand Identity: An Automatic Soap Stamping Machine or even a Semi-automatic Printer adds your unique logo or design, essential for branding.

Professional Packaging: A compact Film Packaging Machine protects the finished bars, enhances shelf appeal, and extends shelf life.

The Benefits: Efficiency, Quality, Scalability

Investing in the right Soap Machine Small Making solution brings tangible advantages:

Reduced Labor: Automation minimizes manual handling.

Consistent Quality: Precise machinery ensures every bar meets your standards.

Space Savings: Compact designs fit smaller workshops.

Scalability: Start small and add complementary machines like a dedicated soap plodder machine for bar soap or an automatic block cutter machine as demand grows.

Versatility: Produce a wide range of soap types effectively.

Finding Your Ideal Small Soap Equipment

Whether you’re setting up a dedicated laundry soap making line, a toilet soap finishing line, or a versatile operation producing both bath and beauty bars, the modern Hot Selling Small Soap Equipment like the Fully Automatic Small Soap All-In-One Machine offers a powerful, space-efficient solution. By combining core processes and offering compatibility with essential finishers like stampers and packagers, it empowers small producers to compete effectively with professional-grade products. Explore your options and take your small-scale soap production to the next level.