Crafting Excellence: Your Complete Soap Production Solution

In today’s competitive market, achieving consistent, high-quality soap requires more than just ingredients; it demands excellent electric soap making chemical equipment and a streamlined process. Whether you’re scaling a mini soap production line or upgrading to a fully automatic soap production line, the right machinery is paramount.

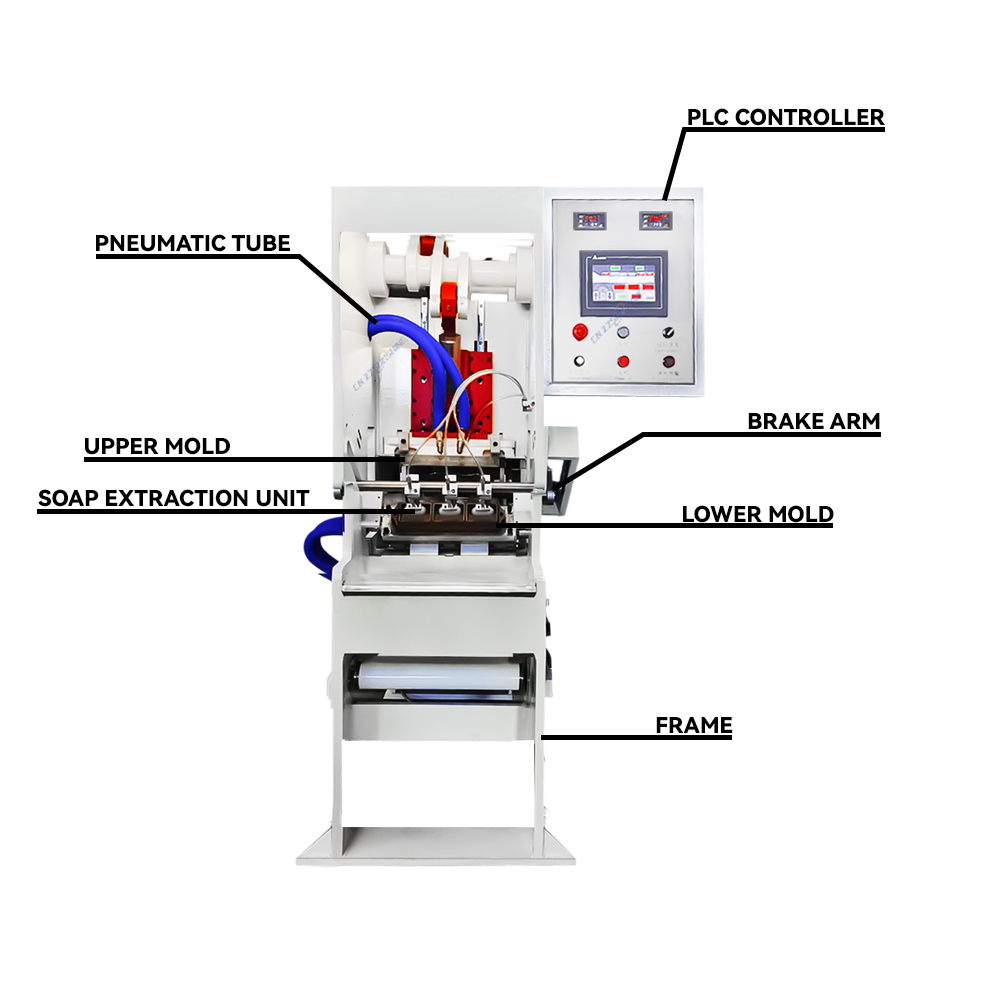

A complete toilet soap making machine setup, or a robust laundry bar soap production line, integrates key components seamlessly. Essential units like the soap mixer ensure homogenous blending of fats and lye. The vacuum plodder, crucial for both toilet soap finishing line and bath soap making machine operations, removes air bubbles to achieve superior density and texture. Precision cutting follows, with options ranging from manual cutting machines to high-speed automatic block cutter machines or pneumatic cutting machines. Finally, branding is applied efficiently using automatic printers or semi-automatic printers, and products are neatly presented with a reliable film packaging machine.

For specialized needs, custom soap cutting machine designs or OEM three roller grinding mill services offer tailored solutions. This integrated approach, from the soap plodder machine for bar soap to the final stamping and packaging, ensures efficiency and product excellence across diverse applications, including beauty soap making lines and laundry soap making lines.

Ready to elevate your soap manufacturing? Let’s talk about optimizing your soap making production line for peak performance.