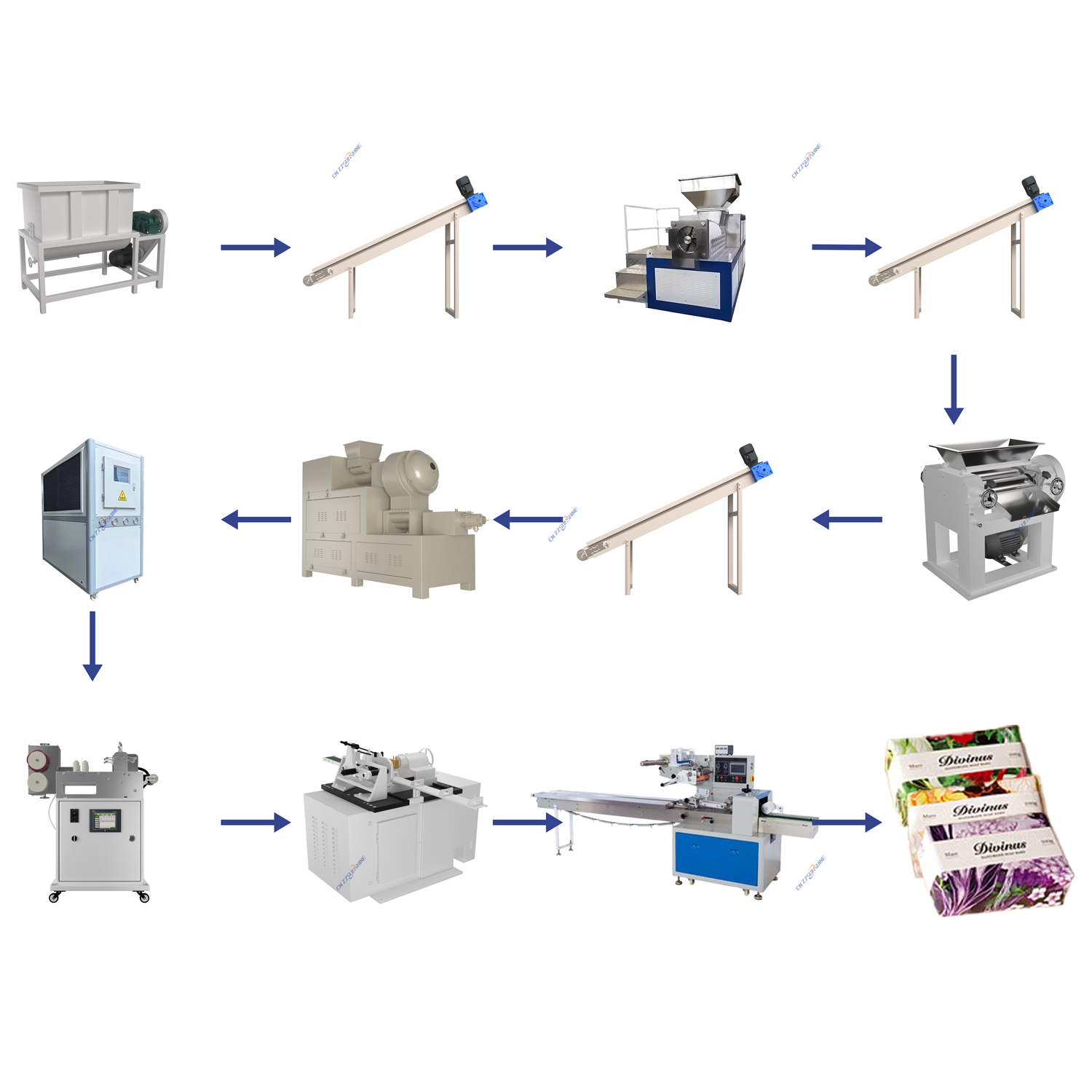

In today’s competitive soap manufacturing industry, efficiency and consistency are critical for success. A modern soap making machine serves as the backbone of any high-output facility, integrating multiple components to streamline operations. For example, the process begins with a soap mixer, which thoroughly blends raw materials like oils and lye to ensure uniform consistency and prevent batch variations. This initial step is essential for producing high-quality bar soaps without costly rework.

Next, the vacuum plodder plays a pivotal role in extruding the mixed soap under controlled conditions, eliminating air bubbles and enhancing texture for a smoother finish. This is particularly beneficial for applications in laundry soap making lines, where durability and user appeal are paramount. Following extrusion, a soap plodder machine shapes the soap into logs, preparing it for precise cutting. Here, a custom soap cutting machine allows manufacturers to achieve exact dimensions tailored to specific products, such as those in toilet soap finishing lines, ensuring minimal waste and optimal aesthetics.

Integrating these elements into an automatic soap production line reduces labor costs and human error, boosting throughput by up to 50%. Technologies like an electric washing soap cutter further improve hygiene and safety, especially in environments handling sensitive bath soaps. For larger-scale operations, a laundry bar soap production line or bath soap making machine can be customized to handle diverse formulations, from industrial-grade detergents to luxury beauty soaps. This adaptability not only cuts production time but also enhances scalability, allowing factories to meet fluctuating market demands without compromising quality.

Ultimately, investing in reliable soap making machinery, including vacuum plodders and automated cutters, translates to significant long-term savings and higher profit margins. By adopting these innovations, manufacturers can maintain stringent quality standards while accelerating output, positioning themselves as leaders in a rapidly evolving industry.