Unlock Sustainable Soap Production: Smart, Affordable Machines for Small Businesses

The demand for eco-conscious personal care products is soaring. Consumers increasingly seek out bath soaps, laundry bars, and beauty soaps made with transparency and sustainability in mind. For small to medium-sized manufacturers, entering this profitable market requires efficient, cost-effective equipment that doesn’t compromise on quality or environmental responsibility. Investing in the right soap making production line is key to achieving this balance.

Essential Equipment for Small-Scale Success

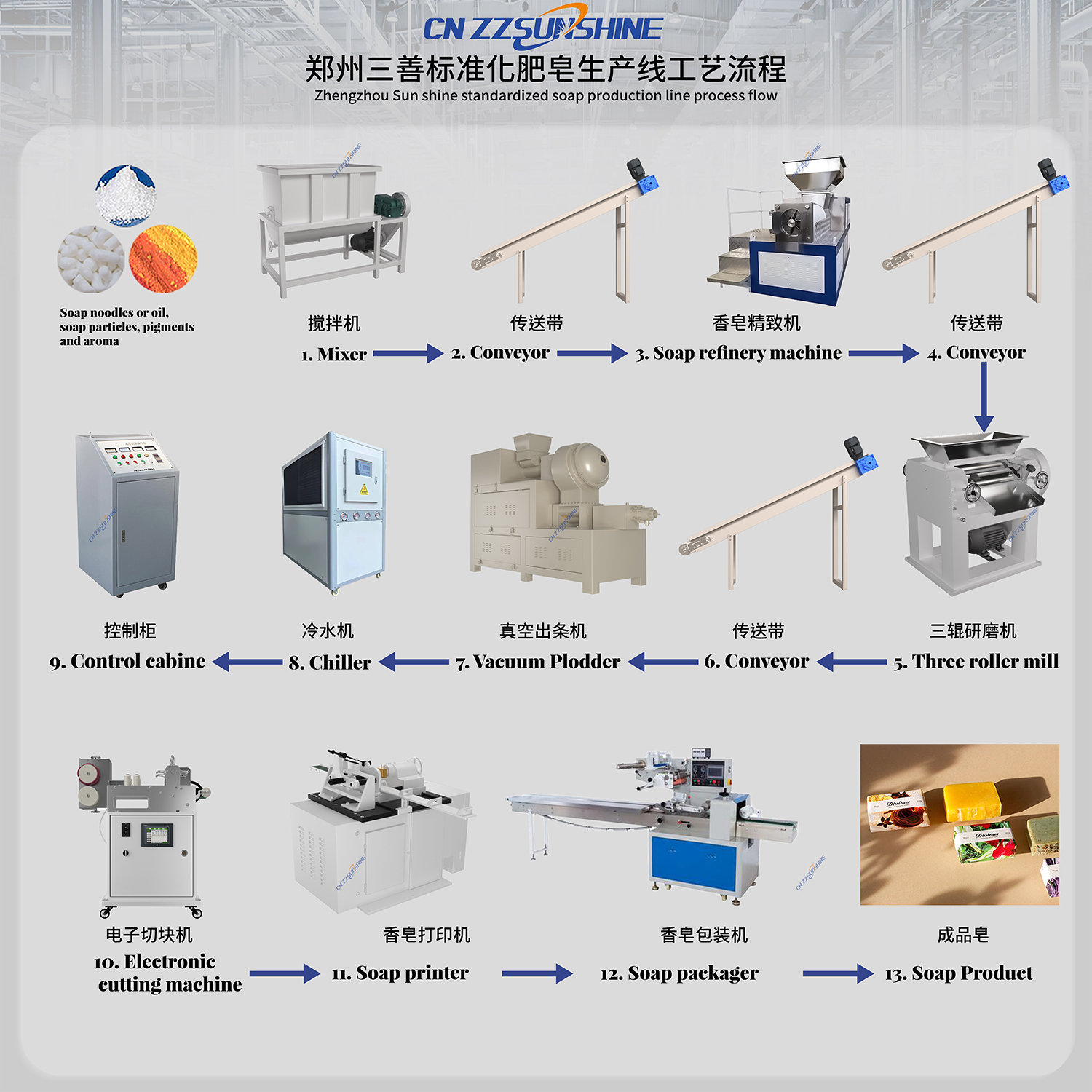

A streamlined operation for high-quality bar soap starts with core machinery designed for versatility and reliability:

1. The Heart of Production: Mixing & Refining: A robust soap mixer is fundamental for thoroughly combining oils, lye, and additives. For achieving the smooth texture consumers expect, especially in toilet soap finishing lines or beauty soap making lines, integrating an OEM three roller grinding mill is crucial. This equipment refines the soap mixture, ensuring a homogenous blend and premium feel.

2. Forming the Bar: Vacuum Plodding: The soap plodder machine for bar soap, particularly a Vacuum plodder, plays a vital role. It compacts the mixed soap base under vacuum, removing air pockets to create a dense, consistent extruded log. This step is essential for both laundry bar soap production line outputs and premium bath soap making machine operations, preventing crumbling and ensuring bar integrity. The soap plodder stage directly impacts the final product’s quality and longevity.

3. Precision Cutting: Efficiency & Consistency: Transforming extruded soap logs into individual bars requires accurate cutting. An automatic block cutter machine offers significant advantages over manual cutting machine options. Options like an Electric washing soap cutter, Pneumatic Cutting Machine, or Electronic Cutting Machine deliver uniform sizing and clean edges with minimal waste, boosting productivity. Whether you need a standard soap cutting machine or a custom soap cutting machine for unique bar shapes, precision cutting is non-negotiable for professional results. This cutter stage is vital in any laundry soap making line or bath soap making machine setup.

Why Choose an Eco-Friendly, Economical Production Line?

Modern soap making machines designed for smaller scales offer compelling benefits:

Lower Initial Investment: Compared to large industrial lines, a Mini Soap Production Line or semi-automatic setups significantly reduce capital expenditure.

Reduced Operating Costs: Efficient machines consume less energy and raw materials. Automatic soap production line components, like an Automatic Printer or Semi-automatic Printer, minimize labor needs.

Enhanced Sustainability: Efficient processes reduce waste. Machines designed for smaller batches allow for easier integration of eco-friendly ingredients and packaging solutions (like those compatible with a Film Packaging Machine). A well-designed Automatic Soap Production Line optimizes resource use.

Quality & Flexibility: Equipment like a soap stamping machine allows for professional branding, while versatile soap plodder and cutting options enable production of diverse soap types – from simple laundry bars to intricate beauty soaps – on the same core line. This flexibility is key for beauty soap making line success.

Building Your Sustainable Soap Business

For entrepreneurs and small manufacturers aiming to produce high-quality, eco-friendly bath soaps or laundry bars profitably, selecting the right machinery is paramount. A thoughtfully assembled line, featuring a reliable soap mixer, efficient Vacuum plodder, and precise automatic block cutter machine, forms the foundation. By opting for soap making machines that balance economic price points with robust performance and environmental considerations, small businesses can effectively compete in the growing market for sustainable soaps. Explore scalable solutions like the Mini Soap Production Line to start your journey towards efficient and responsible soap manufacturing. Partner with equipment suppliers who understand the needs of smaller scale laundry soap making line and toilet soap finishing line operations.