Beyond Suds: The Engine Behind Your Brand – High-Efficiency Laundry & Solid Soap Production

The soap market thrives on consistency and quality. Whether it’s robust laundry bars for tough stains or elegantly finished beauty soaps, the backbone of any successful brand lies in reliable, efficient production. Investing in a well-designed soap making production line is not just about machinery; it’s about securing the future of your product line. This is where robust solutions like the Durable Complete Laundry Soap Making Machine or the comprehensive ZZSS Laundry Soap Production Line come into play, transforming raw materials into market-ready goods with precision and speed.

At the heart of any effective laundry bar soap production line or toilet soap finishing line is the synergy between specialized equipment. The journey begins with blending. A high-capacity soap mixer ensures uniform distribution of fats, oils, alkalis, and additives, creating a homogenous base crucial for consistent quality. For formulations requiring finer texture or incorporation of delicate ingredients, an OEM three roller grinding mill provides the necessary refinement, achieving the smoothness expected in premium products.

The mixed soap mass then moves to the refining stage. Here, the soap plodder machine for bar soap takes centre stage. A Vacuum plodder is particularly vital, working under reduced pressure to eliminate air bubbles. This step is critical for producing dense, long-lasting bars that won’t crumble during use. The plodded soap emerges as a continuous, solid log, ready for shaping.

Cutting this log into precise, individual bars requires accuracy and efficiency. An automatic block cutter machine excels here, delivering uniform blocks with minimal waste. For manufacturers seeking flexibility, custom soap cutting machine options are available, tailored to specific size and shape requirements, whether utilizing Electronic Cutting Machine, Pneumatic Cutting Machine, or Manual Cutting Machine solutions for different production scales. An Electric washing soap cutter is often integrated specifically within laundry soap making lines to handle the denser nature of these bars.

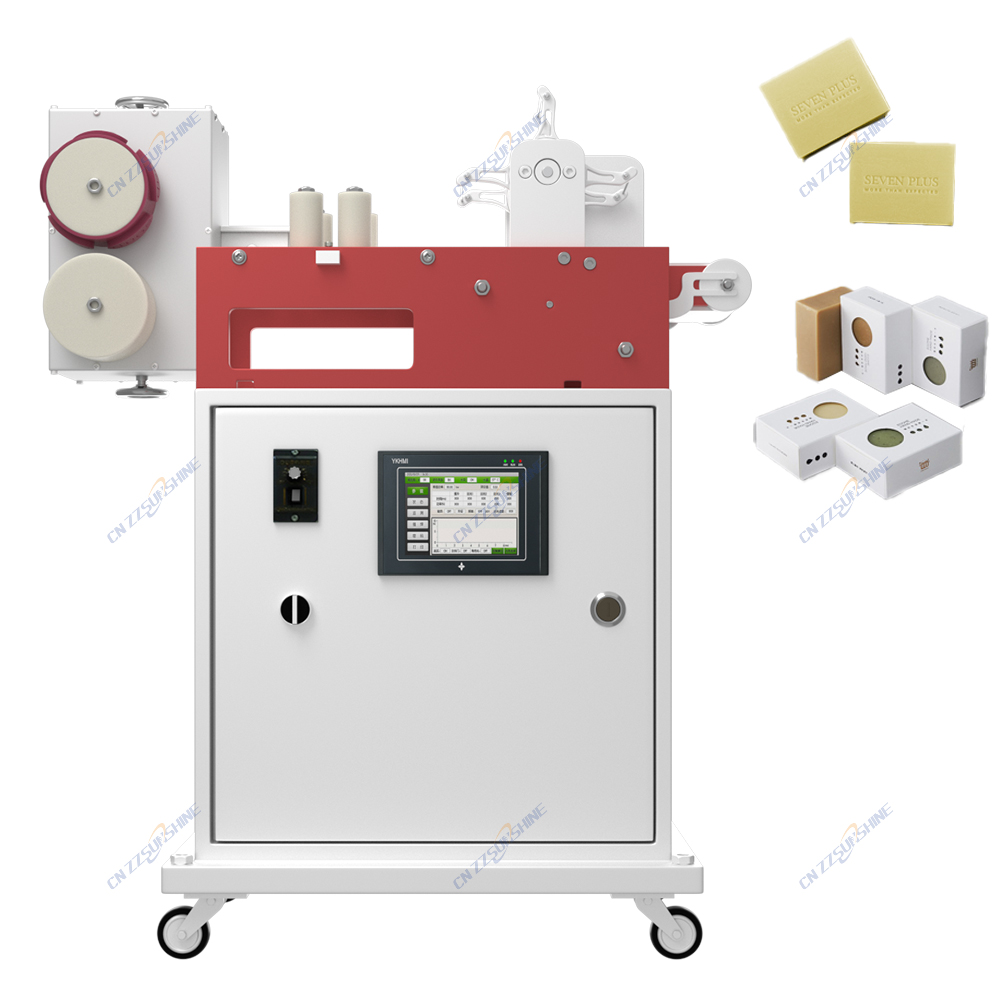

Shaping the brand identity happens next. An Automatic Soap Stamping Machine imparts logos, designs, or product information onto each bar with consistent pressure and clarity. This step transforms a simple block into a recognizable, branded product. For higher volume needs, Automatic Printer systems offer rapid stamping capabilities, while Semi-automatic Printer options provide versatility for smaller batches or intricate designs.

Finally, protecting the finished product is paramount. A reliable Film Packaging Machine ensures bars are sealed hygienically, safeguarding against moisture and damage during transit and storage. This completes the journey from raw materials to a packaged product ready for consumers.

For businesses focused on laundry bars, a dedicated laundry soap making line integrates these components seamlessly, optimized for the specific density and formulation of detergent bars. Conversely, a beauty soap making line or bath soap making machine setup might emphasize finer milling and delicate stamping for premium toilet soaps. The beauty of modern Automatic soap production line solutions lies in their adaptability. Whether you need a full-scale Complete Solid Soap Making Machine installation, a Mini Soap Production Line for niche markets, or specialized Washing Liquid Production Equipment, the machinery can be configured to match your exact output goals and product specifications.

Choosing the right soap making machine partner is an investment in your brand’s reputation and efficiency. Look for providers offering durable equipment, comprehensive solutions from mixing through to packaging, and the flexibility for customization (OEM). A high-performance production line minimizes downtime, maximizes output consistency, reduces waste, and ultimately boosts your bottom line. It’s the silent, powerful engine driving the success of your soap products in a competitive marketplace.