Crafting Quality Laundry Bars: Your Essential Equipment Guide

Producing consistent, high-quality laundry soap bars requires robust and reliable machinery. Investing in a durable laundry soap making line ensures efficiency and product integrity. At the heart of this process lie several key machines designed for soap making.

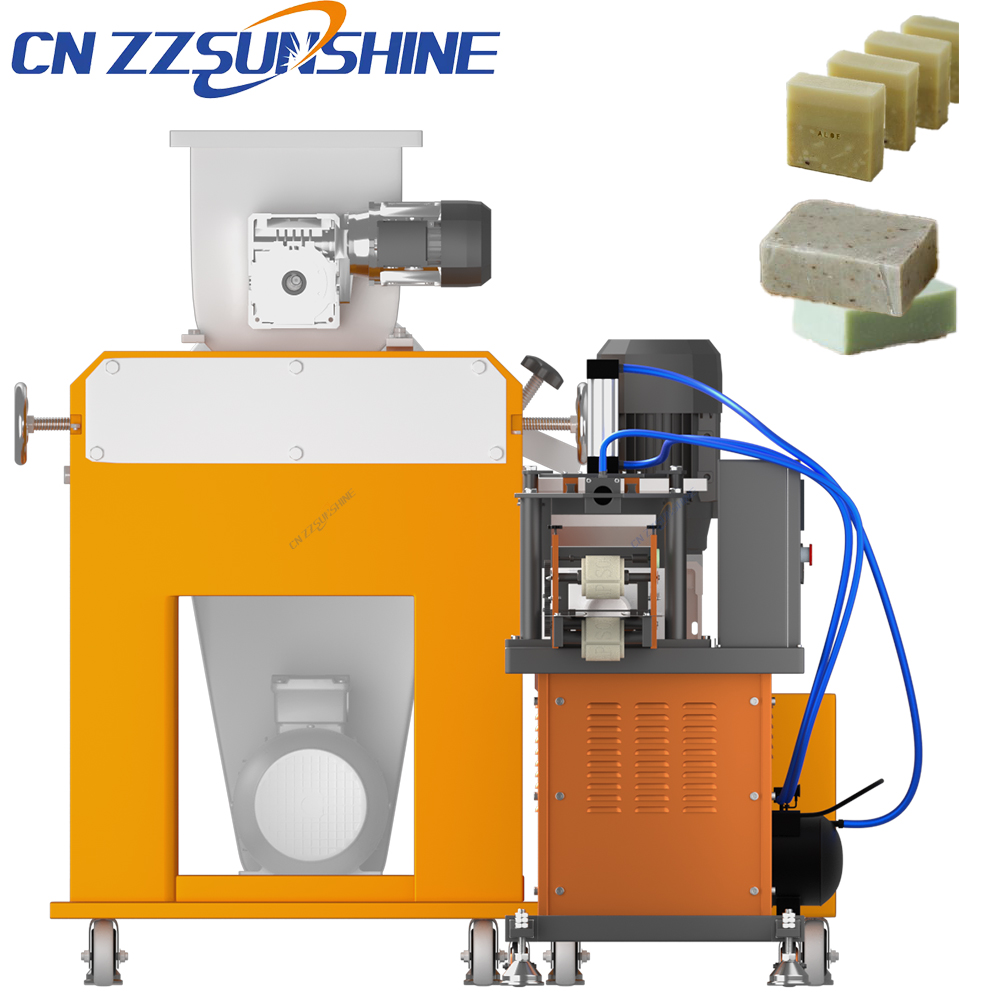

For thorough mixing and refining, a powerful soap mixer combines ingredients uniformly. Following mixing, the three roller mill is crucial for achieving the smooth texture and consistent color demanded by consumers, performing the essential grinding step. The soap plodder then takes this refined mass, compressing and extruding it into a continuous log ready for shaping.

While this trio – the soap mixer, three roller mill, and soap plodder – forms the core refining stage, a complete automatic soap production line integrates further equipment. This includes cutters for sizing the extruded log and stamping machines for branding. Choosing well-engineered, durable machinery, perhaps considering OEM options, provides a low cost path to long-term, efficient production of premium laundry bars.