Finding the Right Fit: Durable & Cost-Effective Soap Production Solutions for Your Business

For small to medium-sized businesses and entrepreneurs venturing into soap manufacturing, finding the right equipment is crucial. The challenge often lies in balancing the need for durable commercial machinery with budget constraints, especially when starting or expanding operations. The idea of sourcing used cheap soap making machine components might seem appealing, but reliability and longevity are paramount for consistent production. This is where exploring well-designed, new China small bar soap making machine options can offer a smarter path to profitability.

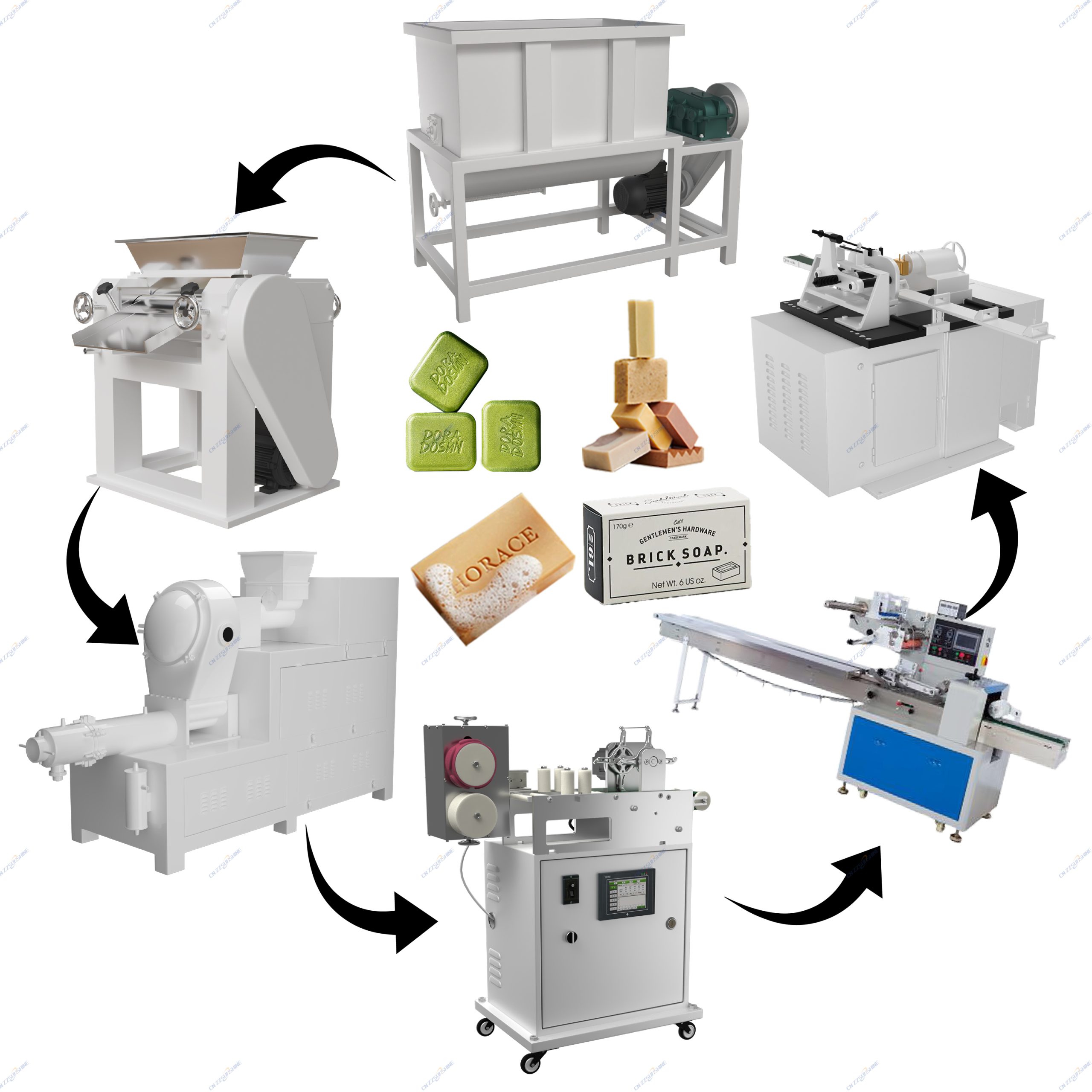

Whether you’re targeting the laundry soap market or diversifying into beauty bars, a well-chosen mini soap production line can be the cornerstone of your operation. Think of it as a scaled-down version of a full automatic soap production line, offering flexibility without the massive capital investment. A typical compact line for laundry bar soap production line or toilet soap finishing line needs might include core components like a robust soap mixer to ensure homogeneous blending of fats, oils, and caustic soda. This is often followed by a soap plodder machine for bar soap, typically a vacuum plodder, which removes air pockets and extrudes a smooth, dense soap noodle or log essential for quality bars.

The extruded soap log then requires precise sizing. This is where an automatic block cutter machine proves invaluable, consistently cutting the log into uniform blocks with minimal waste, far more efficiently than a manual cutting machine. For businesses ready to scale, upgrading to an electronic cutting machine or even a pneumatic cutting machine offers greater speed and automation. Finally, presentation matters. Integrating a soap stamping machine and potentially a film packaging machine completes the line, giving your bath soap making machine or laundry bars a professional finish ready for market.

For manufacturers seeking specific functionalities, options like a custom soap cutting machine or OEM three roller grinding mill (for processes requiring fine milling) can be integrated. The key is partnering with a knowledgeable supplier who understands your needs, whether you require a simple semi-automatic printer or a more comprehensive automatic soap production line. They can guide you towards the most cost-effective soap making production line configuration – robust enough for durable commercial use, yet optimized for your scale and budget. Don’t just look for “used cheap”; invest smartly in reliable equipment designed to grow with your beauty soap making line or laundry soap making line ambitions.