Your Compact Powerhouse: Complete Solutions for Small-Scale Soap Manufacturing

For businesses looking to enter or expand their soap production capabilities efficiently, investing in a tailored, small-scale production line is a strategic move. Whether your focus is laundry bars, premium bath soaps, or beauty soap lines, the right equipment makes all the difference in quality and output.

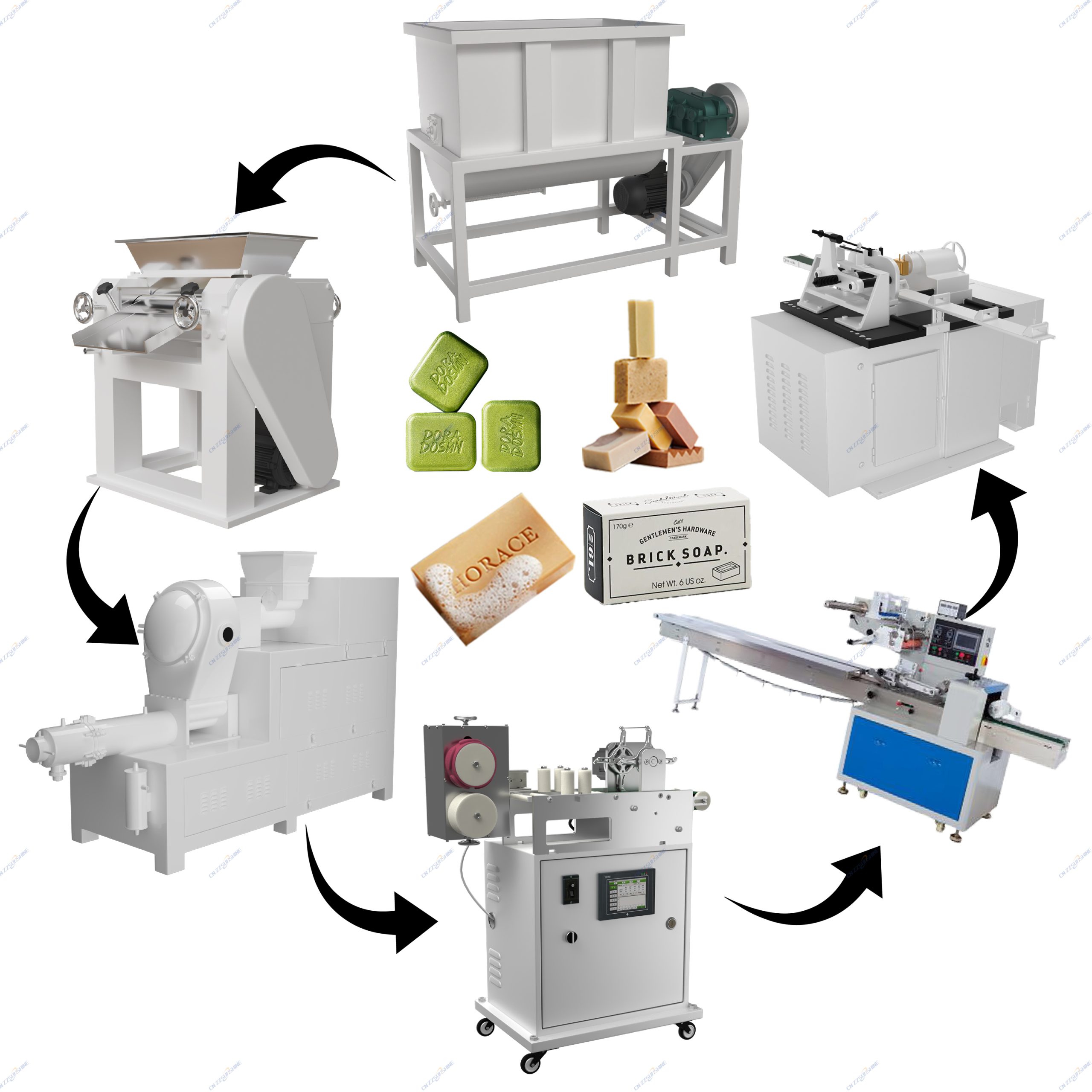

A Complete Solid Soap Making Machine setup, often referred to as a Mini Soap Production Line or Automatic Soap Making Machine Small Line, provides an integrated solution. It typically starts with a robust soap mixer or mixing machine, crucial for achieving the perfect blend of ingredients. This is followed by the core extrusion unit: a soap plodder machine for bar soap, frequently a Vacuum plodder, which compresses and homogenizes the soap mass under vacuum to remove air pockets, ensuring a dense, smooth bar.

Downstream, precision cutting is vital. Options range from Manual Cutting Machines to more advanced Automatic block cutter machines, Pneumatic Cutting Machines, or Electronic Cutting Machines – like the Electric washing soap cutter – each offering different levels of automation for sizing your bars. Finishing touches come from an Automatic Printer or Semi-automatic Printer for branding and a Soap Stamping Machine for final shaping and logo imprint. Packaging is streamlined with a Film Packaging Machine.

The beauty of a Complete Small Soap Production Line lies in its ability to streamline operations from mixing to packaging. These Automatic soap production line configurations enhance efficiency, reduce labor costs, and guarantee consistency in quality. Many manufacturers offer custom soap cutting machine solutions and OEM three roller grinding mill options, allowing you to tailor equipment like the soap plodder and other components to your specific recipe and production goals. This modularity makes them ideal for diverse needs, from laundry soap making line to toilet soap finishing line and bath soap making machine applications. Investing in the right small line is investing in scalable, professional production.