Competitive High Quality Laundry Soap Making Machine/Soap Cutter Cutting Machine/Good Texture Both Soap Producing Machine: Elevating Your Production

In the demanding world of soap manufacturing, achieving consistent high quality and efficiency requires robust, reliable equipment. Whether you’re focusing on laundry bars or bath soaps, the foundation lies in a well-designed soap making production line. Investing in superior machinery is critical to achieving that competitive edge.

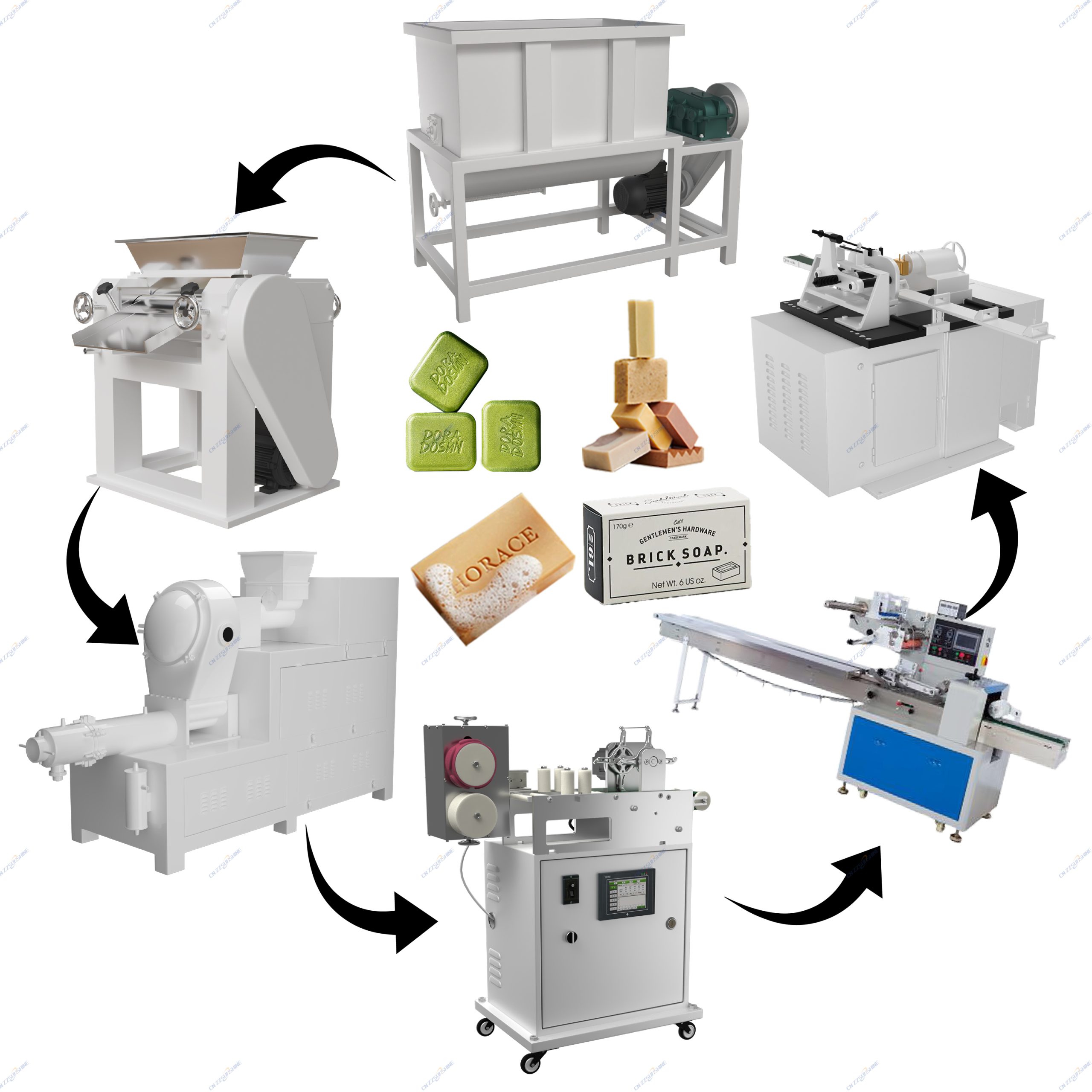

At the core of any successful laundry bar soap production line or toilet soap finishing line are key components like the soap plodder machine for bar soap and the automatic block cutter machine. A high-performance vacuum plodder is essential. It meticulously homogenizes and extrudes the soap base, creating a dense, smooth texture that consumers demand. This extrusion quality directly impacts the final bar’s feel and longevity. Following extrusion, precision cutting is paramount. Advanced soap cutter cutting machines – be they electronic cutting machine, pneumatic cutting machine, or sophisticated automatic block cutter machine variants – deliver clean, uniform cuts with minimal waste, ensuring consistent bar size and weight crucial for branding and packaging.

Furthermore, achieving the good texture both soap producing machine capability often necessitates customization. A custom soap cutting machine can be tailored to specific bar dimensions or complex shapes. Working with experienced suppliers offering OEM solutions for components like three roller grinding mills ensures your soap making machine setup aligns perfectly with your unique product requirements and desired throughput. From the soap mixer and mixing machine stages through extrusion, cutting, and final soap stamping machine application, every piece of equipment, including downstream film packaging machine units, contributes to a seamless automatic soap production line capable of producing top-tier laundry and beauty soaps efficiently.