Unlock Efficiency: Your Guide to Competitive Automatic Soap Making Machines

The soap industry, encompassing everything from luxurious bath bars to essential laundry soaps, demands consistent quality and efficient production. For manufacturers, particularly small to medium-sized enterprises or those seeking to expand, investing in the right soap making machine is crucial. Finding equipment that offers competitive good price without compromising on performance or high quality output can be challenging. This is where modern automatic soap production line solutions, including versatile setups for toilet soap noodles producing machine and compact soap machine small making units, become invaluable assets.

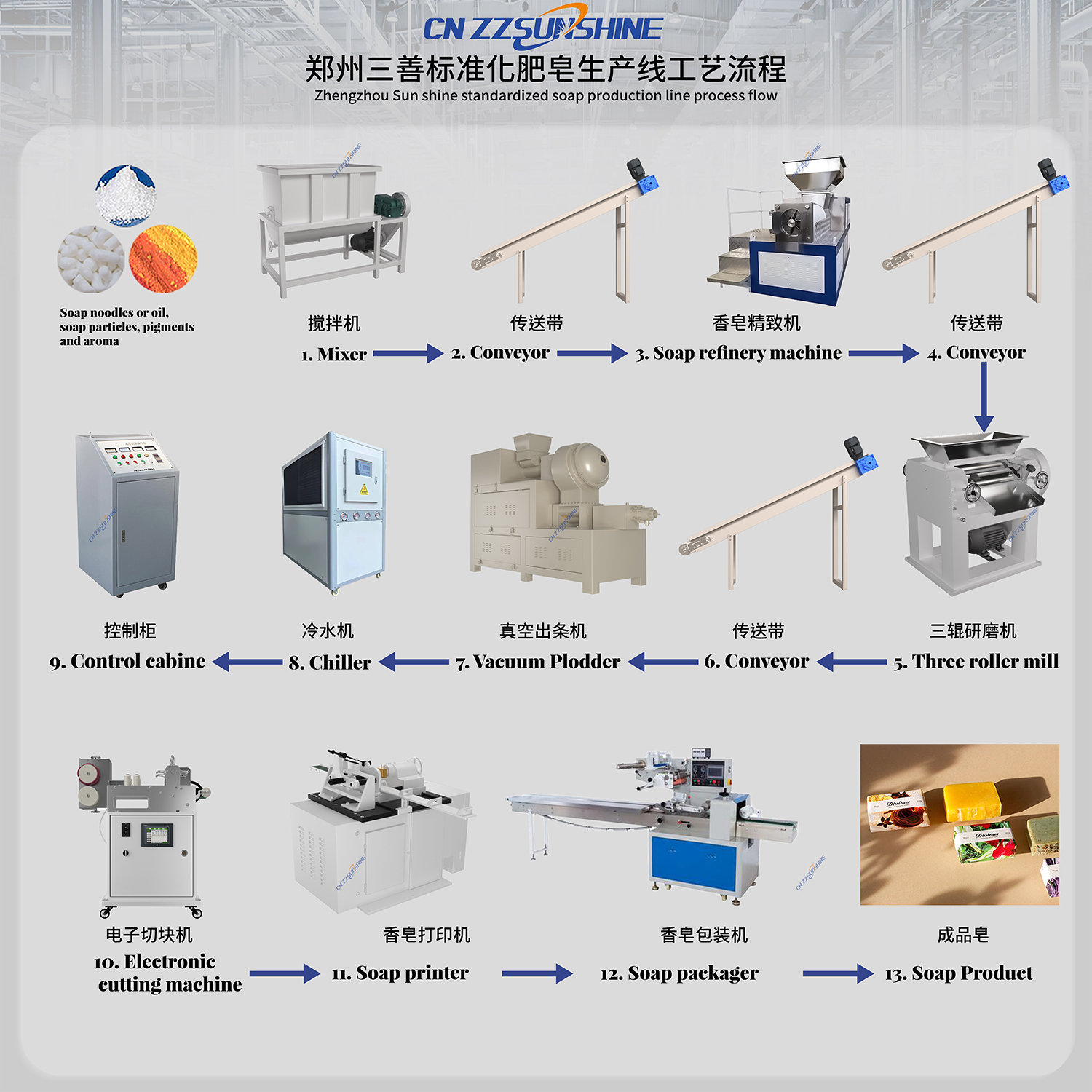

Modern soap making production lines are designed for streamlined operation, minimizing manual intervention and maximizing output. The core process typically involves several key stages, each facilitated by specialized machinery:

1. Mixing & Refining: The journey begins with the soap mixer or mixing machine, where raw materials (oils, fats, caustic soda, additives) are blended into a homogenous paste. For finer texture toilet soaps, an OEM three roller grinding mill is often employed to refine the soap base, ensuring a smooth consistency.

2. Plodding & Compression: The mixed soap is then fed into a soap plodder machine for bar soap. This critical component compresses the soap mass, removing air pockets and creating a dense, uniform extrudate (a continuous soap log). Vacuum plodder variants are particularly effective for high-end toilet soap finishing line and bath soap making machine applications, as the vacuum environment significantly enhances soap density and translucency.

3. Cutting: The continuous soap log exiting the plodder requires precise sizing. Here, an automatic block cutter machine shines, automating the process for high-volume lines. For smaller operations or specialized shapes, options range from manual cutting machine to pneumatic cutting machine or electronic cutting machine. Custom soap cutting machine solutions are also available for unique bar dimensions or shapes.

4. Stamping & Packaging: The cut soap bars move to a soap stamping machine for branding. Finally, a film packaging machine efficiently wraps the finished products, ready for distribution. Semi-automatic or automatic printer options can be integrated depending on the line’s automation level.

The beauty of today’s technology lies in its scalability. A comprehensive automatic soap production line integrates these stages seamlessly. However, manufacturers aren’t limited to massive setups. Mini soap production line configurations offer an excellent entry point, providing automation benefits at a more accessible scale. Similarly, semi-automatic options allow businesses to automate core processes like plodding and cutting (electric washing soap cutter) while retaining manual control for stamping or packaging, optimizing cost versus automation.

For businesses focusing specifically on laundry products, a dedicated laundry soap making line or laundry bar soap production line can be configured. Those specializing in premium or specialty bars might prioritize a sophisticated toilet soap finishing line or beauty soap making line, emphasizing refining and vacuum plodding. The versatility extends further; separate washing liquid production equipment can often be integrated into facilities producing both bar and liquid cleansers.

Why does this matter? Investing in well-designed soap making machinery translates directly to:

Enhanced Productivity: Automation speeds up production cycles significantly.

Consistent Quality: Precise machinery ensures uniformity in bar weight, density, and appearance – crucial for brand reputation, especially in competitive toilet soap and bath soap markets.

Cost Efficiency: Reduced labor dependency and minimized waste contribute to a healthier bottom line. Machines built for durability offer long-term value.

Scalability: Modular designs allow lines to grow alongside your business.

Choosing the right equipment supplier is paramount. Look for providers offering not just machines, but solutions – including custom soap cutting machine capabilities or OEM services for specific components like the three roller grinding mill. They should understand the nuances between a laundry bar soap production line and a beauty soap making line.

In conclusion, achieving efficient, high-quality soap production is within reach. By leveraging modern automatic soap production line technology, including compact soap machine small making units and specialized equipment like the vacuum plodder or automatic block cutter machine, manufacturers can produce competitively priced toilet soap, laundry soap, and bath soap that meets market demands. Careful selection based on your specific product focus and scale ensures optimal return on investment and positions your business for sustainable growth.