The Competitive Edge: Your 50-150 kg/h Toilet Soap Finishing Line Solution

For businesses seeking to establish or scale their toilet soap production, finding the right equipment balance between capacity, quality, automation, and cost is crucial. If your target output falls within the 50-150 kg/h range, investing in a dedicated toilet soap finishing line offers a significant competitive advantage. This focused approach ensures efficiency and hygiene specifically tailored for high-quality bar soap production.

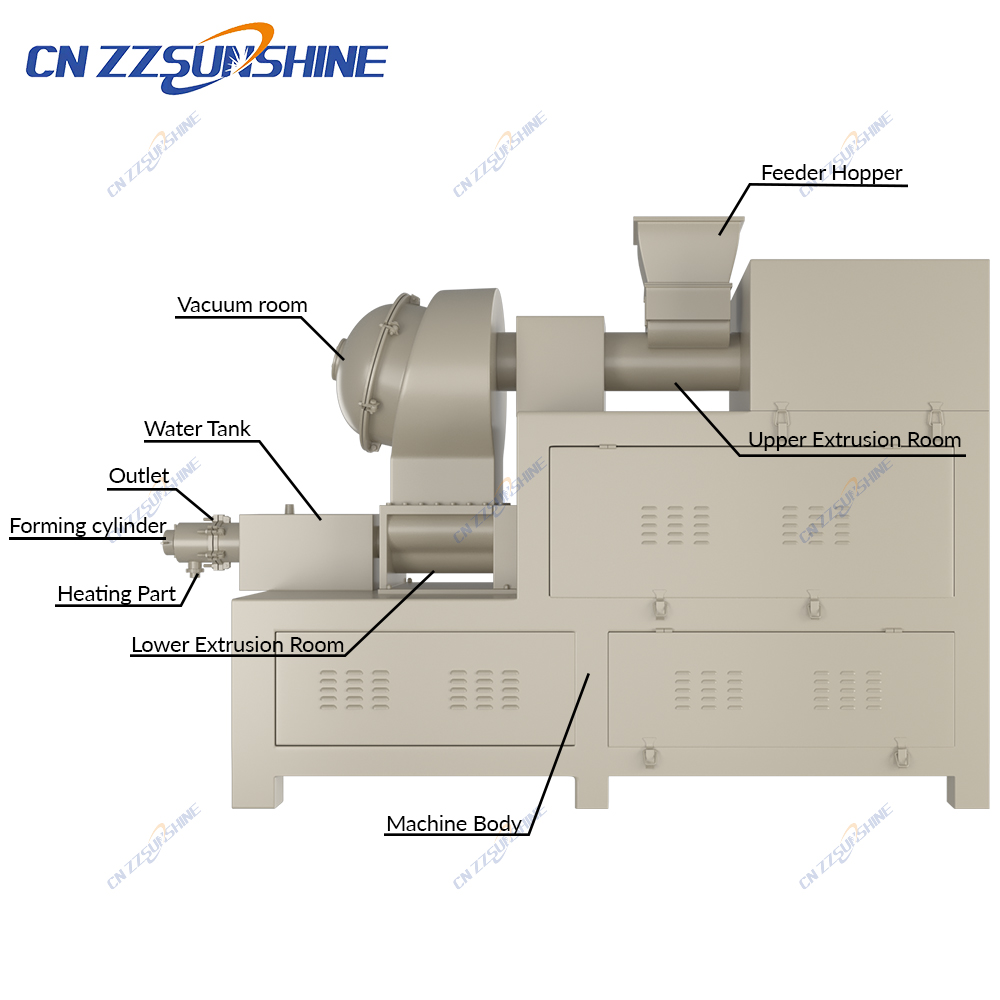

A well-designed toilet soap finishing line for this capacity integrates several key components. At its heart is often a robust soap plodder machine for bar soap, typically a vacuum plodder. This critical unit compresses, homogenizes, and extrudes the soap noodles into a continuous, dense bar, ensuring the final product has the desired texture, firmness, and lather properties. The vacuum function is essential for removing air pockets, resulting in a smoother, more durable bar.

Following extrusion, the continuous soap log moves to cutting. Here, an automatic block cutter machine takes over, precisely slicing the log into individual soap blanks. This automation ensures consistent size and weight for each bar, minimizing waste and maintaining product uniformity far more efficiently than a manual cutting machine. Options range from pneumatic cutting machines to electronic cutting machine variants, offering precision and reliability.

The cut blanks then proceed to stamping and branding. An automatic soap stamping machine imprints logos, designs, or information onto each bar, adding significant value and brand recognition. Finally, a film packaging machine efficiently wraps the finished bars, protecting them from moisture, dust, and damage during storage and transport, while also enhancing shelf appeal.

We offer comprehensive soap making production line solutions specifically configured for this 50-150 kg/h toilet soap segment. Our lines integrate these core units – the soap plodder, automatic block cutter machine, soap stamping machine, and film packaging machine – into a cohesive automatic soap production line. This integration streamlines operations, reduces labor costs, and maximizes hygiene.

The beauty of a dedicated toilet soap finishing line at this scale is achieving near automatic soap production line efficiency without the hefty investment of larger, more complex systems. It provides the perfect springboard for SMEs aiming to produce high-quality toilet soap competitively. Focus on your brand and formulations; let our efficient, cost-optimized finishing line handle the reliable production of beautiful, market-ready bars.