The Engine Room: Understanding the Vital Role of Mixer Tanks in Compact Soap Production Lines

For entrepreneurs and small-scale manufacturers entering the soap industry, navigating the array of equipment can be daunting. While automatic soap production lines often grab attention with their sophisticated automatic printers, soap stamping machines, and high-speed film packaging machines, the true heart of the process often lies in the foundational stages. Specifically, for those seeking efficient mini soap production line solutions, the soap mixer, particularly the critical oil and caustic soda mixer tank, is paramount for both quality and safety.

The initial chemical reaction that transforms oils and fats into soap, known as saponification, is meticulously managed within this specialized vessel. In a typical laundry bar soap production line or a beauty soap making line, precise blending of caustic soda (lye) with oils is non-negotiable. An inadequate mix leads to incomplete saponification, resulting in subpar soap with excess alkali or unreacted oils – problematic for both performance and skin safety. Therefore, a robust and well-designed mixing machine is indispensable.

Modern soap making machines designed for smaller operations, such as those offered by experienced China factory suppliers, often integrate compact yet highly efficient mixer tanks. These units are engineered for thorough agitation, ensuring homogenous distribution of lye within the oil blend. This precision is crucial regardless of whether the subsequent process involves a soap plodder machine for bar soap in a toilet soap finishing line, or simpler manual methods. For operators focusing on laundry soap making lines where consistent alkali content is vital for cleaning efficacy, the reliability of the oil and caustic soda mixer tank directly impacts the final product’s quality.

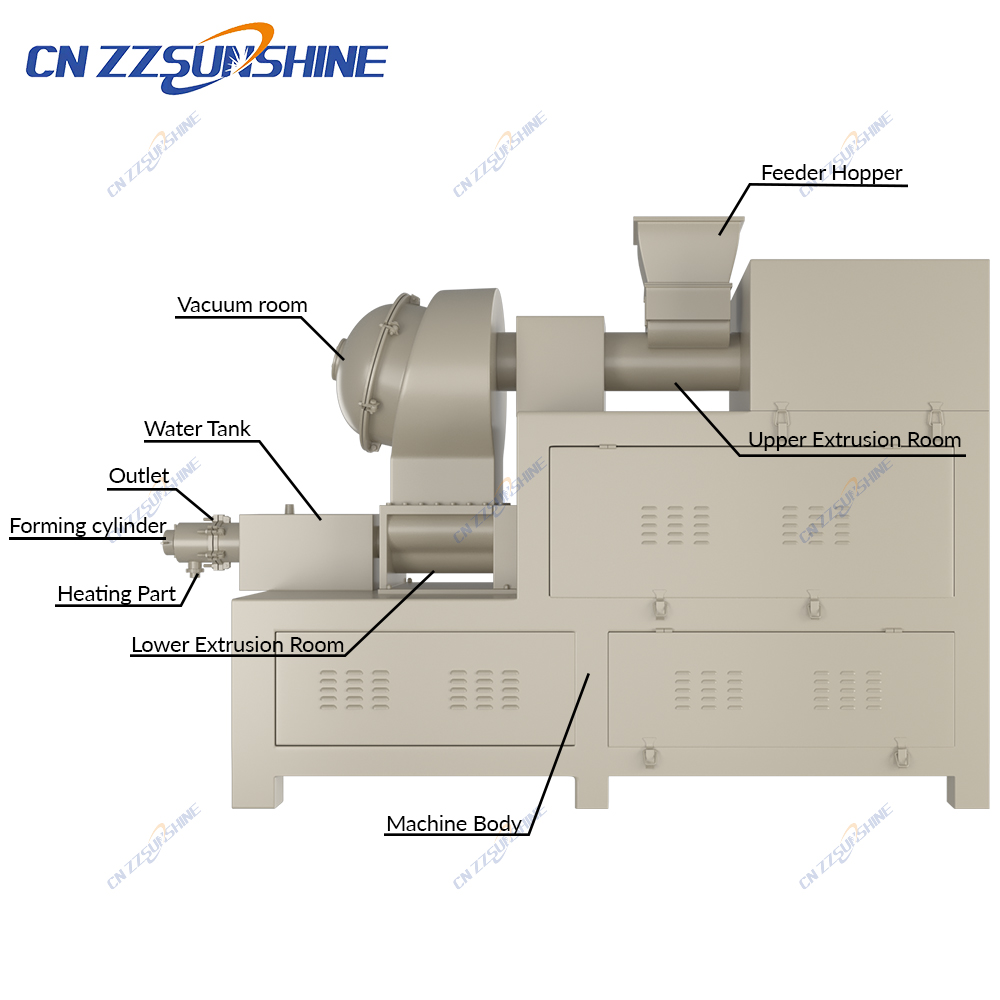

Following the mixing stage, the saponified paste (or neat soap) progresses through the line. Here, equipment choices vary based on scale and automation level. Larger automatic soap production lines might incorporate a vacuum plodder to homogenize and extrude the soap base under vacuum, removing air for a denser bar. Smaller lines, perhaps a semi-automatic printer setup, might utilize a simpler soap plodder. The extruded soap log is then cut into individual bars. Cutting methods range from manual cutting machines suitable for very low volumes to pneumatic cutting machines, electric washing soap cutters, or sophisticated electronic cutting machines for precise, automated sizing. Custom soap cutting machines can also be developed to meet specific bar dimensions or shapes.

For milling processes to refine texture, OEM three roller grinding mills are commonly employed. Downstream, automatic block cutter machines efficiently divide large extruded blocks into manageable units before final stamping and packaging.

Investing in a well-designed small soap line, particularly one centered around a dependable soap making machine mini configuration with a proficient mixer, offers significant advantages. Chinese manufacturers specializing in soap making production lines and washing liquid production equipment provide solutions balancing cost-effectiveness with essential functionality. This allows smaller producers to achieve consistent, high-quality soap batches, focusing on either bath soap making machines for premium products or robust laundry soap making lines. Ultimately, the oil and caustic soda mixer tank serves as the cornerstone, ensuring the foundational chemical process is executed flawlessly, paving the way for success in the competitive soap market.