Crafting Beauty: Essential Machines for Premium Soap Production

The demand for beautifully presented, high-quality soaps – from luxurious beauty bars to functional laundry blocks – is ever-growing. Meeting this demand efficiently requires reliable, precise machinery. Whether you’re upgrading an existing soap making production line or establishing a new mini soap production line, selecting the right equipment is paramount for quality and productivity.

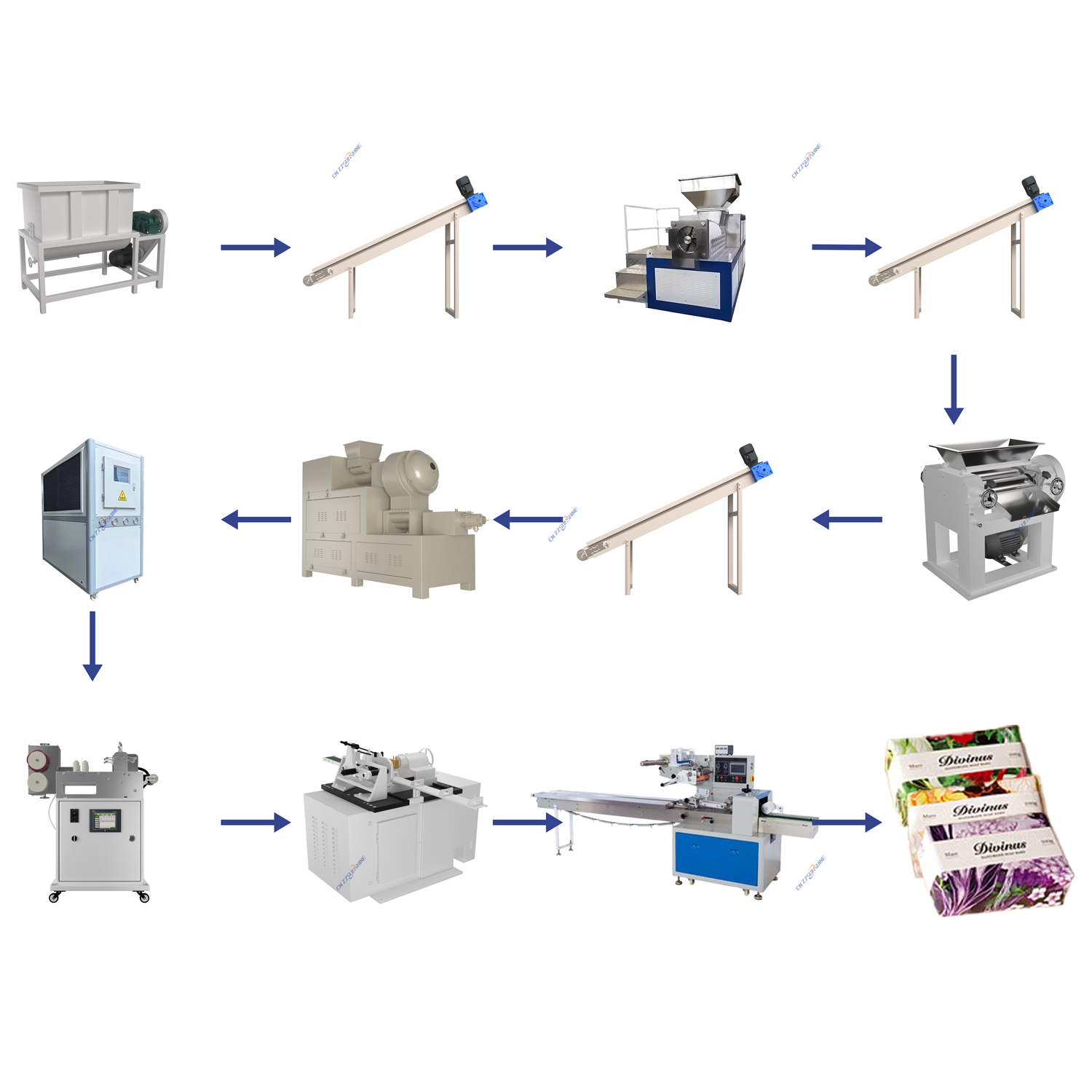

At the heart of soap manufacturing lie core workhorses. The soap mixer or mixing machine ensures consistent amalgamation of ingredients. Following this, the soap plodder, particularly a vacuum plodder, is crucial. It refines the soap mass, removing air pockets for a denser, smoother bar suitable for intricate beauty soap making line products. For grinding and refining, an OEM three roller grinding mill provides the necessary precision.

Cutting accuracy is non-negotiable. Moving beyond basic manual cutting machines, modern solutions like the automatic block cutter machine or pneumatic cutting machine deliver uniform sizing with minimal waste. An electronic cutting machine or electric washing soap cutter offers programmable precision, essential for maintaining brand consistency, especially when paired with a soap stamping machine for branding. This is where a high quality soap cutter cutting machine proves its value.

Finishing touches elevate the product. A beauty logo press printing making machine allows for elegant, custom branding directly onto bars. Finally, efficient wrapping is handled by a film packaging machine, completing the toilet soap finishing line or laundry bar soap production line.

Partnering with a knowledgeable factory direct soap product machine manufacturer ensures access to robust soap making machines, including custom soap cutting machine options. They can provide integrated solutions, from a semi-automatic printer to a fully automatic soap production line, streamlining operations. Investing in the right soap plodder machine for bar soap, efficient cutters, and precise finishers is key to producing beautiful, market-ready soap products effortlessly.